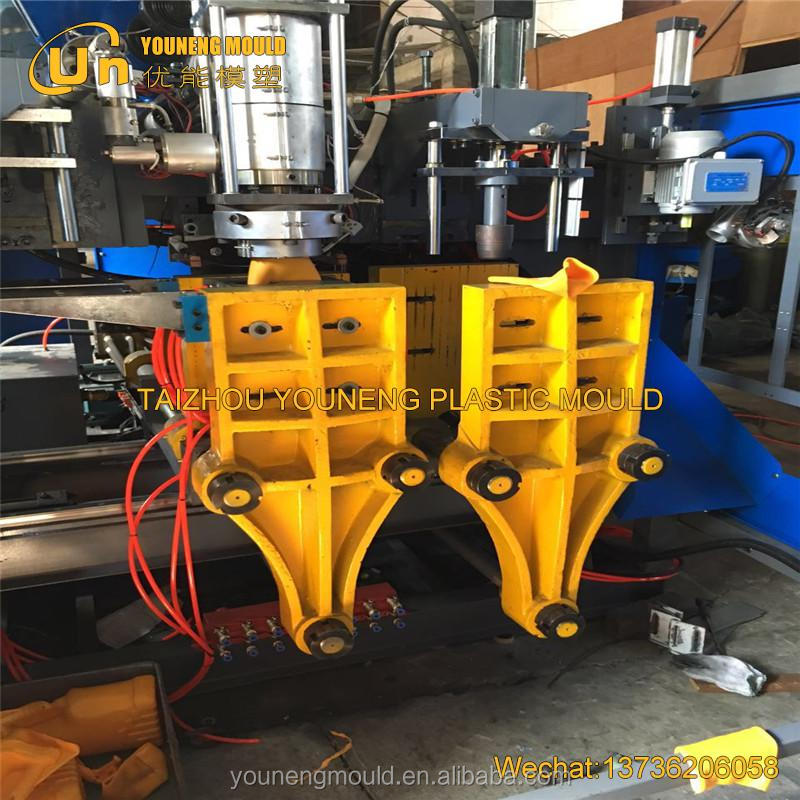

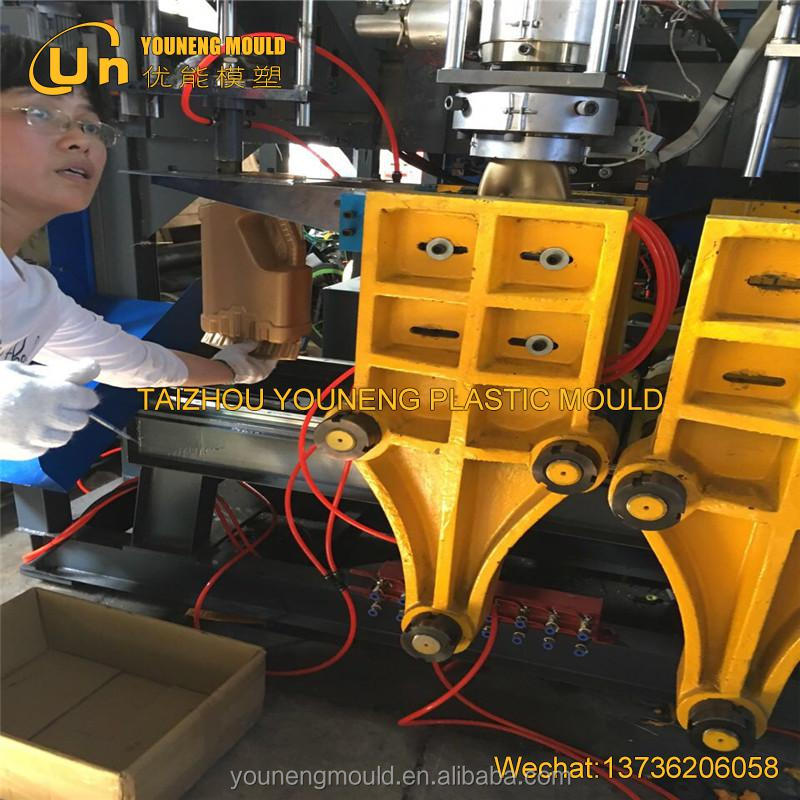

2016 new hollow blow molding machine plastic extruder

- $5000.00 / 1 - 1 sets

$4800.00 / >=2 sets - 1 set

- Taizhou Youneng Plastic Mould Co., Ltd.

- Zhejiang, China

- Ms Ms Vicky

| Certification: | ISO9001 | Main selling points: | multifunctional |

| After warranty service: | spare parts | Core components: | pressure vessel |

| Video shipment inspection: | if | Packaging Details: | wooden box |

| Power (watts): | 7.5 kW | Plastic processing: | pet |

| Power (kW): | 240 | Supply capacity: | 300 sets per year |

| application: | bottle | port: | Ningbo |

| payment terms: | T/T, Western Union | place of origin; place of origin: | Zhejiang, China |

| Voltage: | 220V | Applicable industries: | manufacturing plant |

| Core component warranty: | 1 year | Blow molding type: | blow mold |

| After-sales service provided: | Engineers available overseas to service machinery, on-site maintenance and repair services | brand: | friendship |

| automation: | automatic | Dimensions (L*W*H): | 5.9*3.4*3.9m |

| Warranty: | 1 year | weight: | 800 kg |

| State of health: | new | Showroom location: | not any |

| Local service location: | not any | Mechanical test report: | if |

| Weight (kg): | 100 | Marketing Type: | 2019 Hot Products |

| model: | 001 | automatic: | No |

Specification

benefit:

1. Low failure rate in the first 5 years. The life span is more than 15 years.

2. With safety light curtain. Ensure the safety of workers without affecting the automatic operation of the machine.

3. Equipped with stainless steel blowpipe. In order to prevent the blowpipe from being cooled and rusted to block the water pipe.

4. Equipped with thickened linear rolling guide rail with 65mm guide rod for mold station movement. Compared with the 45-50mm guide rod used by other manufacturers, this machine has a longer life.

5. The automatic lubrication control system is an innovative design, which can renew the lubricating oil. Pump a certain amount of lubricating oil to each point. Collect used oil for cleanliness and environmental protection, while extending the life of the machine.

6. Precise secondary filtration system for hydraulic oil, with detector and indicator. Keep the hydraulic oil clean and ensure the long life of the hydraulic system.

7. Hydraulic oil precision secondary filtration system with detector and indicator. Keep the hydraulic oil clean and ensure the long life of the hydraulic system.

8. The movement of the mold station is equipped with servo valves and high-precision electronic calipers, and PQ closed-loop control. Make the movement of the mold station more stable and energy-saving

9. The structure of the blowpipe rack and mold table is more stable, and there is no hook to resist the external force of the blowpipe.

10. Equipped with energy storage air compressor and water, oil and dust separation system, which makes the pneumatic system more stable and has a longer life.

11. Equipped with a large hard tooth surface extrusion machine to ensure high efficiency, energy saving and long life.

12. Thickened high-quality chrome-plated guide rod, high efficiency and energy saving, long life.

13. Digitally produced accessories ensure that we can replace it as long as it is the same.

| technical specifications | ||

| Maximum container capacity | large | 30 |

| Screw diameter | mm | 85 |

| Screw aspect ratio | aspect ratio | 24/1 |

| Extruder driving power | kilowatt | 30 |

| Number of heating zones | Area | 4 |

| Screw heating power | kilowatt | 8.4~9.6 |

| Mold heating zone | Area | 3 |

| Mold heating power | kilowatt | 5~7 |

| capacity | large | 3.5 |

| Maximum needle diameter | mm | 350 |

| Oil pump driving power | kilowatt | 18.5 |

| clamping force | KN | 200 |

| Platen distance | mm | 400~1000 |

| Maximum mold size (WxH) | mm | 650x750 |

| blowing pressure | MPa | 1 |

| The amount of compressed air used | cubic meter/hour | 0.8 |

| Cooling water consumption | cubic meter/hour | 0.3 |

| cooling water pressure | MPa | 0.4 |

| Machine Dimensions (LxWxH) | rice | 4.2x2.7x3.5 |

| machine weight | Ton | 11 |

Thank you for reading and trying our products, if you have any other questions, please feel free to contact us through the information below, thank you!

Mr Vicky

sales Manager

---------------------------------------------------- ----------------------------------