Biscuit make machine small

- $11000.00 /set

- 1 set

- Jinan Delon Machinery & Equipment Co., Ltd

- Shandong, China

- Mr Jack Su

| Packaging Detail: | Wooden Cases; | Raw material: | Wheat Flour and soya cake,Milk,Corn,Fruit,Wheat,Nuts,Soybean,Flour,Vegetables,Water; |

| Local Service Location: | None; | Port: | Qingdao port; |

| Application: | Biscuit processing; | stainless steel: | ss304/202/316; |

| Weight: | 3500kg; | Power: | 29kw/118KW; |

| Key Selling Points: | Automatic; | Voltage: | 220V/380V/415V/440V 50HZ/60H; |

| Warranty: | 1 Year; | Showroom Location: | None; |

| Application fields: | Snack food factory,Bisciut making; | Usage: | bisciut making; |

| Place of Origin: | Shandong, China; | electrical equipment: | ABB(or customized; |

| Material: | Stainless Steel; | Type: | Fully Automatic; |

| Product name: | Cookie Making Machine; | Output product name: | biscuit; |

| Condition: | New,New; | Function: | making biscuit; |

| Applicable Industries: | Food & Beverage Factory,Food & Beverage Shops,biscuit or cookie factory; | Dimension(L*W*H): | 17m*0.6m*1.34m; |

| Package Preview: | ; | Certification: | ISO/CE; |

| Machinery Function: | biscuit making; | Brand Name: | DELON; |

| Supply Ability: | 20 Sets per Quarter Biscuit make machine small; | After-sales Service Provided: | Field installation, commissioning and training; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Payment Terms: | L/C,T/T,Western Union,MoneyGram; |

Biscuit make machine small

Biscuit can be divided into soft biscuit and hard biscuit ,according to recipe,process,different molding methods.Soft biscuit through the roller machine can be molding.Hard biscuit need to go through three pressure roll,and then through the mold roll forming, scrap on the back to feeding bucket.

This small integrated machine for soft biscuit and hard biscuit can meet your demand of making soft biscuit and hard biscuit bothly.

Different dough roll width meets different productivity capacity. So please provide as much detail as possible so that we can provide more professional advice.

1.The kinds of biscuit you will produce. You can provide the sample pictures.

2.The production capacity you need. Different model meets different productivity capacity.

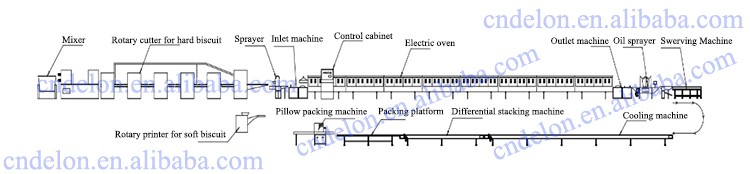

Biscuit make machine small of powder-mixer,peel-fold machine,candy-filling machine, molding machine,egg-brushing grain-scatter machine,tunnel stove ,swerve machine , oil-sprayer,cooling transmission,suger/salt-pouring machine and so on.

Biscuit make machine small is the company digestion and absorption of Japanese technology, novel design, compact structure, high degree of automation equipment, from feed rolling, molding, waste recycling, drying, fuel injection, cooling automatic one-time completed, the company, to provide users with hundreds of mould and dozens of technological formula, by changing the mould and process recipe can produce market popular all kinds of high-grade cookies, such as butter cookies, biscuit, thin biscuit, soda biscuit, multi-dimensional animal crackers, cookies, vegetables, cookies, etc.

Layout for biscuit make machine small

Parameters of biscuit make machine small

Sample for biscuit make machine small

Main Features for biscuit make machine small

1> Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2> Inspect the machine before leaving the factory.

3> Oversea install and debug the equipment.

4> Train the first-line operator.

5> Provide the basic formula

How are biscuits made in a factory

The production of biscuits in a factory include the steps of mixing, molding, baking and cooling. These are the four primary stages of biscuit production.

The first step involves feeding the ingredients – flour, sugar, fat and so on – into the mixers to prepare the dough. The mixing phase is usually done more than once with different speeds, but flour characteristics also play a role.

The next step requires the dough to be laminated and transferred to gauge rollers. It is in this stage that biscuits receive their shapes, either through cutting or molding.

The third stage has the biscuits baking inside of the oven where radiation, convection and conduction give the biscuits the correct color and volume. The biscuits are carried into the oven on a wire mesh band.

In the cooling stage, biscuits are placed onto 300- to 400-foot cooling conveyors to cool at room temperature. According to Delon, natural cooling is preferred over forced cooling in order to maintain the texture quality of the biscuits.

The biscuits are then feed into packaging machines to be inserted into slug packs, pouch packs or family packs to be shipped to retailers. Industry and regulatory standards require that quality control checks be performed at every step of production.

Mixer

Function:Kneading flour machine is stirring machine which crumples up folur powder and water into dough or other materials and is independently used with other machines.

Power: 0.75kw

Dimension: 1280*1280*620mm

Rotary cutter for hard biscuit

After putting stirring flour powder into the machine, they are one time shaped into unripe biscuit, all kinds of middle and high grade biscuit and thin biscuit through three stages roller and roll cutting molds.

Rotary printer for soft biscuit.

Put the mixed flour into the machine, and roll it into a biscuit raw embryo, and make various medium and high-grade biscuits into the oven.

Oven

Function: Unripebiscuit is processed with long time baking system under lower temperature after it enters into infrared ray baking fumace transmitted by belt in order to make biscuit ripe.

Dimension: 2*0.51*0.9m (For one)

Power: 20.5kw

Sandwich machine. Optional

This machine is used to make sandwich biscuit.

Oil spray machine

Undry biscuit out of baking out of baking furnace immediateiy enters into oil-spraying machine, which is necessary for production of high-grade biscuit, to better improve grades and colors of biscuit.

Cooling machine

This machine used to cool the biscuit before the biscuits are delivered to the packaging machine to ensure the quality of the biscuits after packaging and to extend the shelf life.

Packing machine.

This model is suitable for packaging biscuits. The utility model has the advantages of novel structure, beautiful appearance, low noise, stable operation, low failure rate and convenient maintenance.

Pre-Sales Service

a). Supplier should trial run whole line at supplier's factory before shipment;

b). Supplier has to run the machine at least 1hour for each product;

c).Twin screw extruder All raw materials for that trial run to be arranged by supplier at their cost.

After-Sales Service

a). Free consultation service before, during, and after sales;

b). Free project planning and design services;

c). Free debugging of equipment until everything is functional;

d). Free management of equipments long distance shipping;

e). Free training of equipment maintenance and operating personally;

f ). Free new production techniques and formulas;

g). Provide 1 year complete warrantee and life-time maintance service.

| Size | |

| Weight | |

Jinan Delon Machinery & Equipment Co., Ltd. is a high and new technology enterprise integrating technology, manufacture and trade. We have devoted ourselves to developing, manufacturing and trading double/single screw extruders, snack production lines, breakfast cereal/corn flake production lines, soya meat production lines, pasta/macaroni production lines, pet food production lines, etc. for more than 10 years.

Q:Are you manufacturer?

A: Yes, we are manufacturer, welcome to visit our factory and check the machines.

Q: Can you design new mold for us if we have good idea?

A: Yes,we can design new mold for you according to your original market needs.

Q:Can you help us to design the whole line if we provide the layout of our factory?

A:Yes,we can provide you machine layout at your factory after get your factory details.

Q: What information should I provide, if I want a quotation?

A:┅The kind of machine you choose, or offer me the kinds of food you will produce.

--- Your production capacity requirement.

---Provide us your production details, then we give professional suggestion to you.

Q: Why choose us?

A: --- Professional technology, we have been engaged in manufacturing food processing machine for many years, accumul ating rich experience and enjoying high reputation.

┅Fast delivery and good service.

┅All the machines are strictly inspected before making shipment.

---Alibaba assessed supplier.

---Provide basic formula.