China carbon graphite vacuum pump blade vt 4.8

- $20.00 / 4 - 49 pieces

$15.00 / 50 - 199 pieces

$10.00 / 200 - 999 pieces

$5.00 / >=1000 pieces - 4 pieces

- Zhenjiang Ecigar Machinery Co., Ltd.

- Jiangsu, China

- Mr DAVID QIN

| application: | Vacuum pump/air pump/vane pump | brand: | Eka |

| Ash content: | ≤100PPM | Bulk density: | 1.8-2.1 g/cm3 |

| Material: | High purity graphite | model: | ZYBW/ZBW/YBW/TPL/VFT/DFT |

| hardness: | 85 Shore | Origin: | Jiangsu, China |

| chemical composition: | carbon | payment terms: | wire transfer |

| grade: | Similar to EK60 | sample: | free (in stock) |

| Porosity: | ≤21% | Specific resistance: | ≤15μΩ-m |

| Maximum applicable temperature: | 200℃ | Compressive strength: | ≥80Mpa |

Product Description:

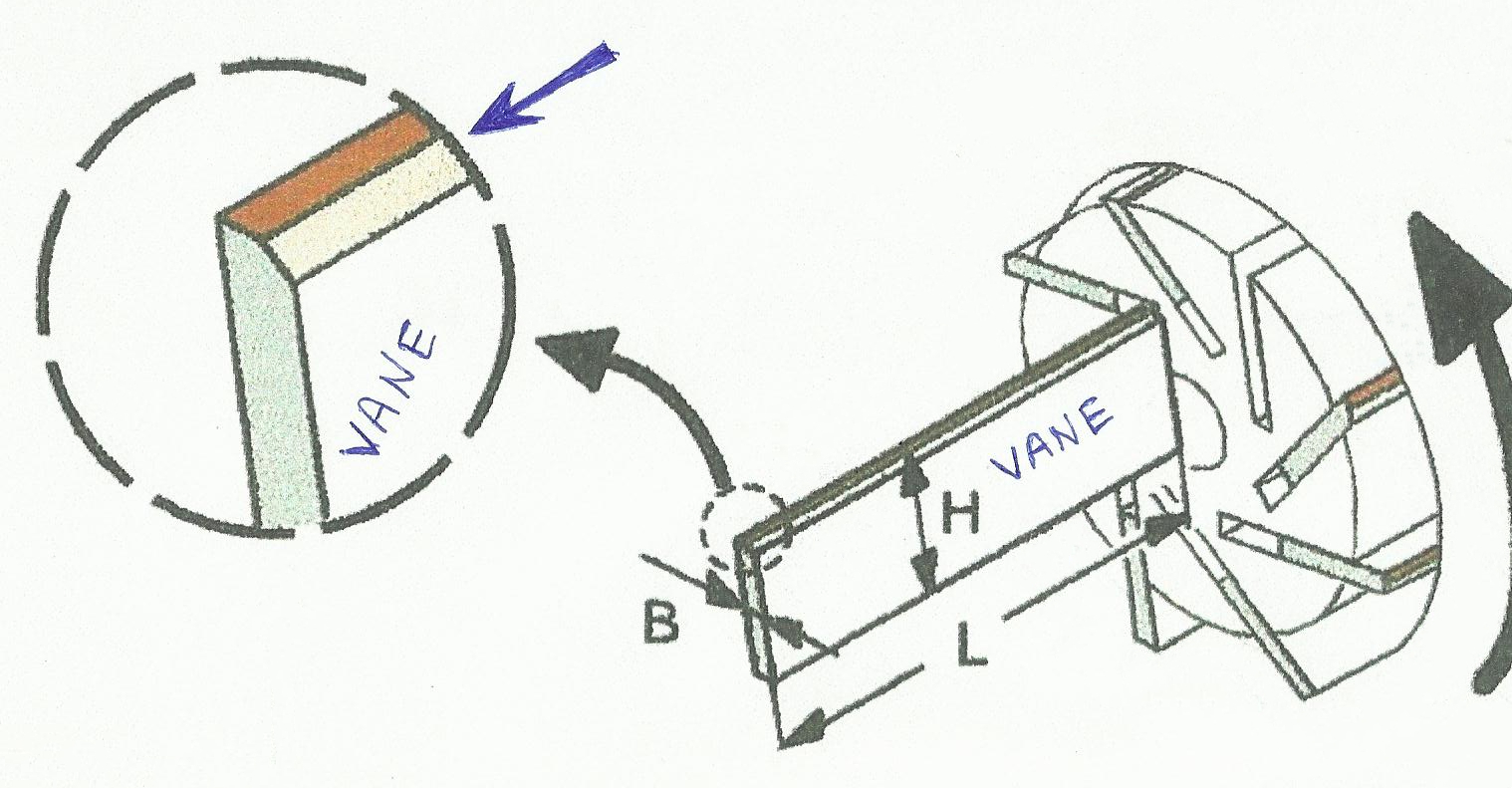

We can specialize in the manufacture of various sizes of carbon graphite blades for oil-free vacuum pumps and compressors. As one of the core components of the pump, the carbon vane has strict requirements in terms of material properties, machine size and shape and position tolerances. At the same time, as a vacuum pump manufacturer, the quality of carbon blades has been widely verified and recognized in the long-term use of vacuum pumps. We provide carbon leaf matching for many domestic pump manufacturers, distributors and users. Our pumps, components and carbon vanes have been exported to more than 40 countries and regions.

How to get the carbon blade size you need?

1, Show the nameplate of your pump.

2. To measure, measure its length, width and thickness. But if you measure old blades, the width is not accurate because the blades are worn and shorter than original. At this point the depth of the rotor slot can be measured to obtain the width of the blade.

3. Determine the number of each group: the number of rotor slots is the number of blades in each group.

Tips for using carbon leaf:

1. When using a new pump, pay attention to the direction of the motor, and do not connect it backwards. Prolonged reverse rotation of the pump can cause damage to the vanes.

2. There is too much dust in the working environment of the water pump, and incomplete air filtration will accelerate the wear of the blades and reduce the service life of the blades.

3. Humid environment will cause corrosion of blades and rotor slot walls. When the air pump is started, the blades cannot be thrown out of the position, and the blades are damaged due to uneven force. In this case, first check the blades and clean them up.

4. When using the air pump, frequent switching will increase the number of throwing impacts of the blades and reduce the service life of the blades, which should be avoided as much as possible.

5. Poor quality blades will cause the performance of the air pump to decline or damage the inner wall of the cylinder, so they should be avoided.

How to replace new carbon blades:

Caron blades are consumable materials, and wear to a certain extent will affect the performance of the air pump and eventually damage it. At this point you must replace the blades with new ones.

1. Before replacing new blades, clean the rotor groove, air pump cylinder wall, cooling pipe and filter air bag with compressed air.

2. Check whether the cylinder wall is worn (too hard material blades will wear the cylinder wall). If the cylinder wall is damaged, the air pump will generate noise when it is running, and the blades will be easily damaged.

3. When installing the blade, pay attention that the slope direction of the blade is consistent with the arc of the rotor groove (or the low point and high point of the slideway width are consistent with the low point and high point of the rotor groove depth). If the blade is installed upside down, the blade will get stuck and break.

wind vane plot.png

4. After replacing the blades, first unplug the connecting air pipe, start the air pump, discharge the residual graphite debris and dust in the air pump, and then take over the pipe for use.

Commonly used models for reference:

Chinese model:

F models: ZYBW60F, ZYBW80F, ZYBW100F, ZYBW140F, ZYBW250F

E models: ZYBW60E, ZYBW80E, ZYBW100E, ZYBW140E, ZYBW250E

Model B: ZYBW60B, ZYBW80B, CLFT101DV, ZYBW140B, ZYBW160B;

G model: ZYBW25G, ZYBW40G, ZYBW60G, ZYBW80G, ZYBW100G, ZYBW140G

Others: ZBW10B, ZYBW25, ZYBW40; TPL8V, TPL16V; VFT40, VFT60, VFT80, VFT100

German models:

KTA50, KTA60, KTA80, KTA100, KTA140; DTA140; VTA60, VTA80, VTA100, VTA140, VTA140; DTE3, DTE6, DTE8, DTE10; VLT10, VLT15, VLT25, VLT40, VLT60; DLT10, DLT15, DLT25, DLT40 ,DLT60; KTA50, KTA60, KTA80, KTA100, KTA140; DTA140; VTA60, VTA80, VTA100, VTA140, VTA140; CLFT61DV, CLFT81DV, CLFT101DV, CLFT141DV

DVT2.60, DVT3.60, DVT2.80, DVT3.80, DVT2.100, DVT3.100, DVT2.140, DVT3.140; DVFLT250, TLF260.KVT3.100, KDT3.100, KVT3.80, KDT3. 80, KVT-3.60, KDT3.60. VT3.10, VT3.16, VT3.25, VT3.40; DT3.16, DT4. 40; VT3.3, VT3.6, VT4.8, VT4.10, VT4.16, VT4.25, VT4.40;

Japanese model:

KRX-1, KRX-3, KRX-5, KRX-6, KRX-7A, KRA-8, KRA-10, KRA-12; CBX-15, CBX-25, CBX-40, CBX-62

Common size for reference:

| 32*16*3 | 63*43*4 | 120*40*4 | 160*29*5 | 190*38*4 | 240*40*4 |

| 40*24*3 | 66*39*4 | 120*40*5 | 160*37*4 | 200*29*5 | 240*48*4 |

| 41*18.5*3 | 85*39*4 | 130*40*4.8 | 160*40*5 | 200*34*4 | 240*48*5 |

| 45*18.5*3 | 85*47*4 | 130*45*5 | 162*50*7 | 200*36*5 | 240*55*6 |

| 48*24*3.5 | 95*38*5 | 130*52*4 | 170*35.5*4 | 200*40*4 | 250*39*4 |

| 55*27*3 | 95*43*4 | 130*52*5 | 170*35.5*5 | 215*52*5 | 250*42*5 |

| 55*39*4 | 95*47*4 | 147*48*7 | 170*39*4 | 220*88*6 | 260*52*5 |

| 60*31*4 | 95*59*6 | 147*58*7 | 180*40*5 | 228*73*8 | 265*45*4 |

| 62*31*4 | 100*52*5 | 150*27*4 | 180*55*5 | 230*40*5 | 280*87*8 |

| 63*34*4 | 110*29*5 | 150*38*4 | 185*55*5 | 230*47*4 | 285*62*4 |

| 63*36*4 | 120*27*4 | 155*38*5 | 190*27*4 | 239.5*36*4 | 355*65*5 |

Other Products

-

Cost Price Becker kvt 3.140 Vanes for Carbon Arrows$5.00 - $20.00 / piece

Cost Price Becker kvt 3.140 Vanes for Carbon Arrows$5.00 - $20.00 / piece