Hqd Gdk125-18-24z/5.5 380v Stone Engraving 5.5kw Water Cooled Spindle for Metal Stone Engraving

- $350.00 /piece

- 1 piece

- Jinan Hongyang Cnc Machinery Co., Ltd.

- Shandong, China

- Ms Tiny Li

| model: | GDK125-18-24Z 5.5kw | Video outbound inspection: | if |

| Model: | 5.5kw metal engraving spindle motor | strength: | 5.5kW |

| application: | Milling, drilling | brand: | high quality development |

| drive: | motor,motor | Certification: | not any |

| Sales unit: | Single product | Running speed: | 24000rpm,6000-24000rpm |

| origin: | Chinese mainland | Single piece packaging size: | 45X35X28 cm |

| current: | 11A | Gross weight of single piece: | 25.000kg |

| Warranty: | 6 months | Core components: | engine |

| Maximum torque: | 2.39 nautical miles | speed: | 18000-24000 rpm |

| Applicable industries: | Machine repair shop | Health status: | new |

| Weight (kg): | 25 | Marketing type: | normal product |

| Place of origin: | Jiangsu, China | Showroom location: | United States, France, Germany, Philippines, Saudi Arabia, Indonesia, Pakistan, Spain, Morocco, Kenya, Chile |

| Mechanical test report: | if |

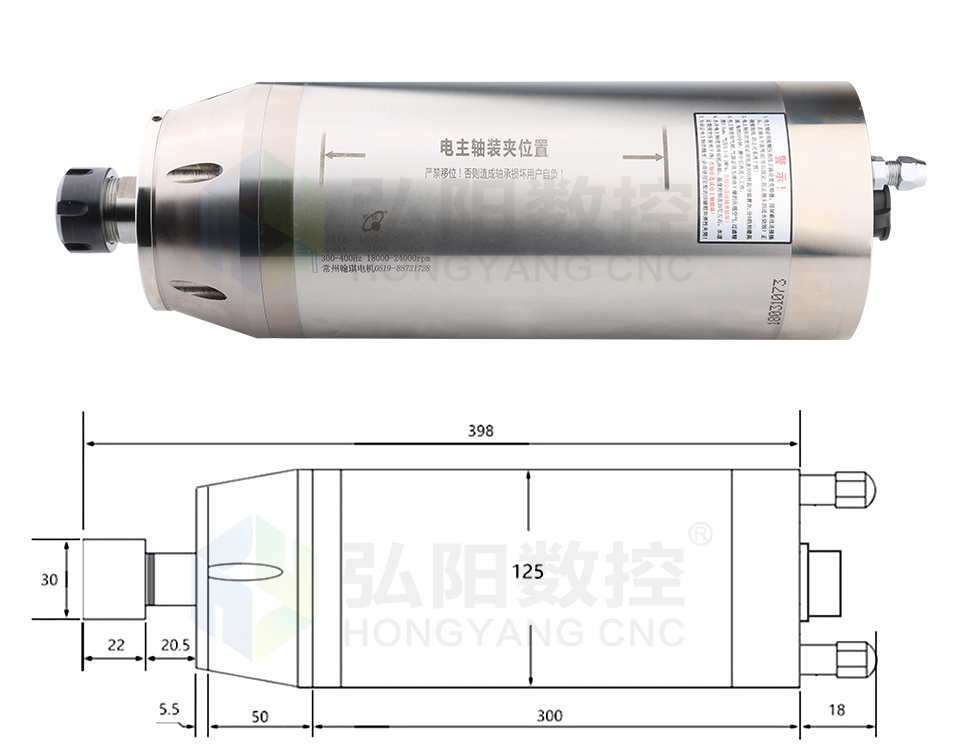

Model: GDK125-18-24Z/5.5kw

Model: GDK125-18-24Z/5.5kw

Size: 125x415mm (body diameter: 125mm x length: 415mm)

Speed regulation method: three-phase output frequency converter, changing the spindle speed by changing the frequency of the frequency converter.

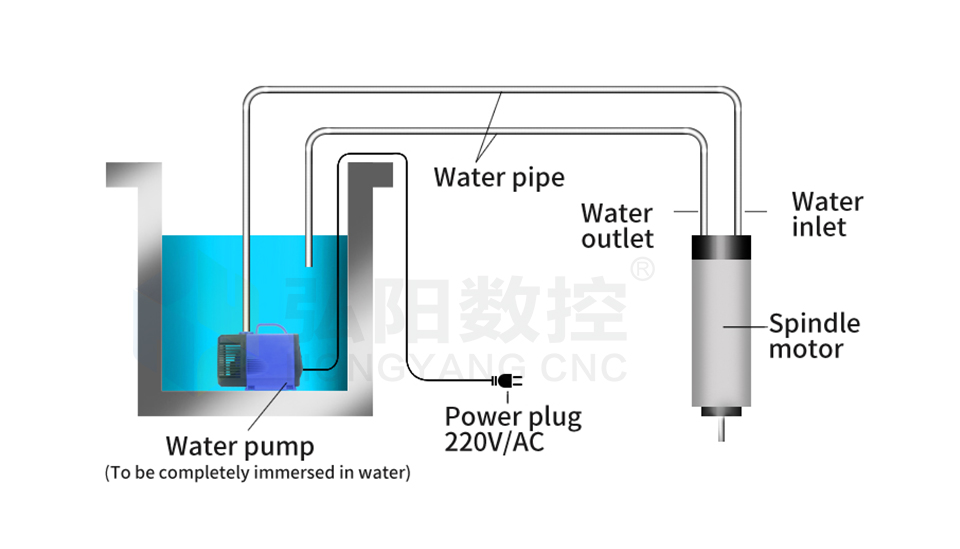

Cooling method: water cooling

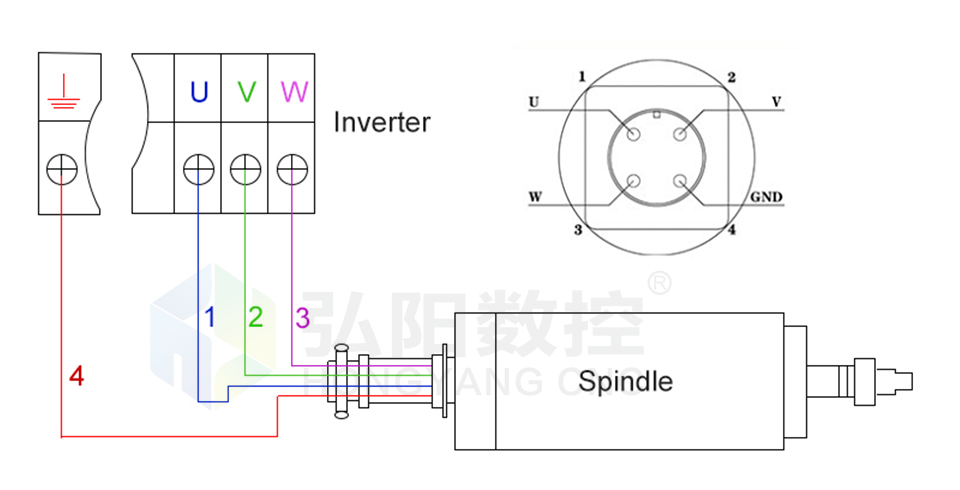

Power interface: optional 4-pin waterproof aviation plug. The aviation plugs marked "1", "2", "3", "4", "1", "2", "3" have been connected to the inverter (U, V, W), 4 of them have Connect to inverter equipment ground.

Power: 5.5kw

Voltage: 380V

Current: 11A

Frequency: 300-400Hz

Speed: 18000-24000rpm

Taper hole: 2UM

Diameter (mm): 125

4 fully sealed angular contact ceramic bearings

Chuck: ER25

Grease lubrication

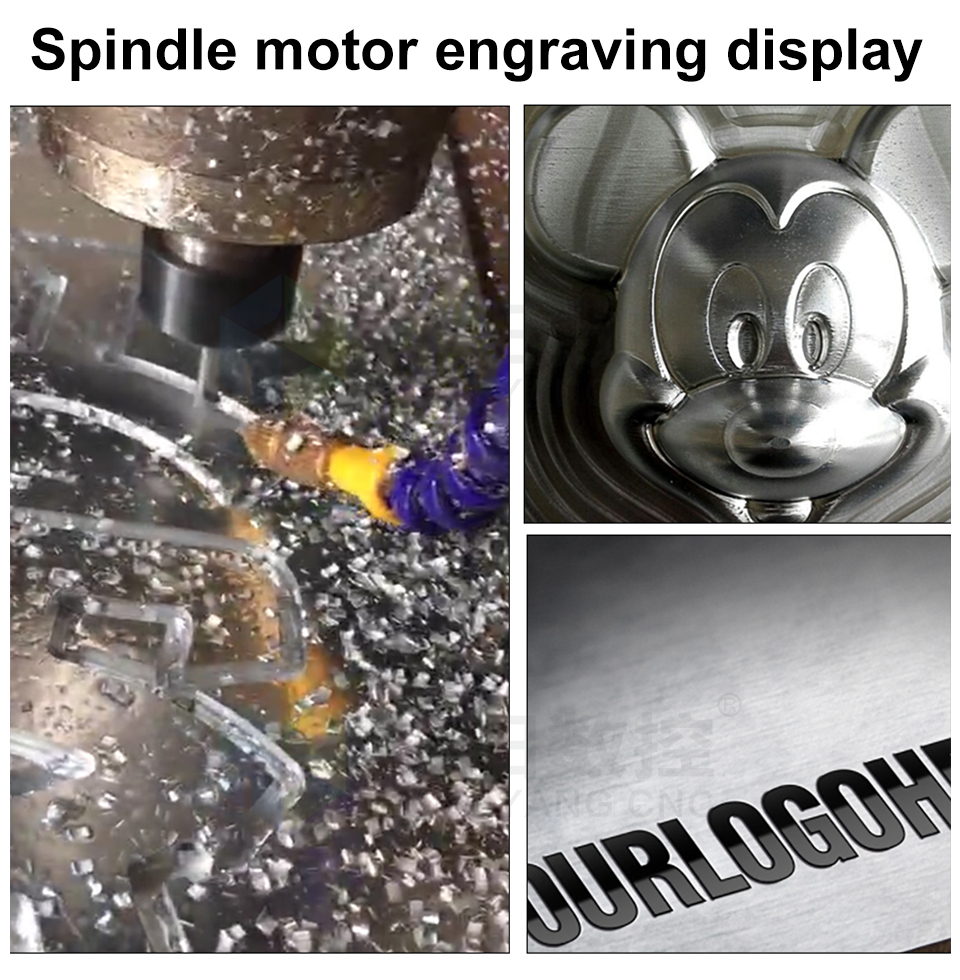

Main uses: engraving wood, bamboo, ordinary PCB, PVC, PMMA, plastic, two-color board (ABS) and other non-metals. It can also engrave gold, silver, copper, aluminum, lead and other soft metal surfaces, ETC.

The working environment temperature of the spindle is usually -10℃~40℃.

Before installing the first electric spindle, turn the spindle head by hand. It should feel flexible and free of sticking.

P4 fully sealed angular contact ceramic bearings extend the life of the spindle.

The longer the length, the greater the torque and the greater the power.

Careful assembly makes the spindle more precise.

Accuracy 0.01mm, coaxial cable less than 0.0025mm

1. Our spindle uses 4 bearings.

2. Bearings are resistant to high temperature and low heat

3. Ceramic ball bearings have low friction, low noise and long service life.

When the HQD CNC spindle motor is stored and transported, the bearing condition in the high-speed grease will change. Customers should run it at low speed for 30 minutes. Then slowly increase the speed to 3000 rpm, running for 20 minutes each time. The lathe spindle and frequency converter should work together. The specifications and parameter settings of the frequency converter match the spindle parameters.

When connecting the inverter spindle, the three-phase inverter power cord should be welded to plug 1 (U), 2 (V), 3 (W) pins and ground pin 4. After turning on the power, observe whether there are any abnormalities. The rotation axis of the HQD CNC spindle motor always displays the direction. If they are inconsistent, shut down the machine immediately and replace the two three-phase power supply wires connecting the inverter and the lathe spindle.

Before using the spindle every day, it must be run at low speed for 15-20 minutes. Clamp the tool on the HQD CNC spindle motor. The chuck nut, chuck, and tool must be clean enough. The shank inserted into the chuck must be larger than 15mm.

The water-cooled lathe spindle must be used with a water pump. Otherwise, the spindle will break quickly.

AC spindle motor must be used in conjunction with a frequency converter. The power of the frequency converter needs to be equal to or greater than the power of the spindle. Before use, please set the inverter parameters suitable for the HQD CNC spindle motor. Otherwise, the spindle and frequency converter will be damaged immediately.

When using the HQD CNC spindle motor, the noise is different from before, please stop the spindle immediately. You need to replace the spindle bearings.

1. Different cooling methods: the water-cooled spindle motor uses water circulation to cool the heat generated by the high-speed rotation of the spindle, while the HQD CNC spindle motor uses fan cooling for cooling.

1. Different cooling methods: the water-cooled spindle motor uses water circulation to cool the heat generated by the high-speed rotation of the spindle, while the HQD CNC spindle motor uses fan cooling for cooling.

2. Noise: The lathe spindle motor has basically no noise, but the air-cooled spindle motor is very noisy.

3. Lifespan: Water-cooled spindle motors should be maintained and maintained frequently, and the water should be changed frequently or an industrial water cooler should be used. The air-cooled spindle fan mainly blows heat to the radiator through wind to achieve a cooling effect.

4. If you need to use metal, hardwood, granite, or stone, you can choose a metal mandrel. Metal mandrels are much better than wooden mandrels.

The frequency conversion power supply of the HQD CNC spindle motor is connected to the rated voltage, and the frequency should be consistent with the technical parameters of the electric spindle. Adjusting the lathe spindle speed can change the frequency, and the voltage also changes proportionally.

The frequency conversion power supply of the HQD CNC spindle motor is connected to the rated voltage, and the frequency should be consistent with the technical parameters of the electric spindle. Adjusting the lathe spindle speed can change the frequency, and the voltage also changes proportionally.

Do not use the spindle and use compressed air to blow out the stagnant coolant in the pipeline. To prevent rust, plug water holes. The spindle should be oiled. Add wave protection and place in a dry place.

Spindle bearings should be replaced by professional technicians. Special tools should be used to thoroughly clean the bearings without removing the stator coils.

hycnc wholesales CNC milling machine spare parts and components and accessories for over 10 years.

Jinan Hongyang CNC Machinery Co., Ltd. has more than 30 employees and nearly 10 years of experience in the sales and assembly of CNC milling machine accessories. Since 2014, Hongyang has offices and warehouses covering an area of more than 5,400 square meters. Hongyang's CNC business sales cover 140 countries and regions. Hongyang is a long-term partner of many powerful CNC engraving machine manufacturers at home and abroad. Hongyang has a warehousing department, technical service department, market development department, domestic sales department, foreign sales department, visual design department, finance department, after-sales department, etc., and continues to provide a full range of high-level comprehensive services for many CNC engraving machine users and Manufacturers in various ways.

Hongyang CNC always adheres to the concept of "survive by quality, develop by reputation, and focus on orders by service". With high-quality products, good reputation, and high-quality services, the products are sold well in 3 provinces, municipalities, and autonomous regions across the country, and exported to Asia, Europe, Africa, South America, Oceania, North America, etc.

It is deeply welcomed and praised by customers at home and abroad. Hongyang is willing to cooperate with you with cost-effective products and high-quality services to establish a mutually beneficial and win-win business relationship and share the value and benefits we strive to create. Together with Hongyang, we will create a greater cause.

Other Products

-

Pneumatic coolant spray seals for metal cutting$0.55 / piece

Pneumatic coolant spray seals for metal cutting$0.55 / piece -

gear rack and pinion design for cnc machine$3.00 / piece

gear rack and pinion design for cnc machine$3.00 / piece -

Hycnc 1.25m 1.5m 2m Gear Curved Straight Industrial Racks Manufacturers Mounting Pinion Steel Cnc Machine Power Steering Rail$13.00 - $16.00 / piece

Hycnc 1.25m 1.5m 2m Gear Curved Straight Industrial Racks Manufacturers Mounting Pinion Steel Cnc Machine Power Steering Rail$13.00 - $16.00 / piece