Lanning small mini scale for waste tire and plastic recycling pyrolysis plant to fuel oil

- $29600.00 /set

- 1 set

- Henan Lanning Technology Co., Ltd.

- Henan, China

- Ms Anne Wang

| Weight (KG): | 15000 KG; | Worker need: | 2-3person; |

| Usage: | Waste Recycling To Enegy; | Marketing Type: | New Product 2021; |

| Heating material: | coal,wood,natural gas,oil; | Equipment Capacity: | 1-3T; |

| Applicable Industries: | Manufacturing Plant,Energy & Mining; | Reactor life span: | 6-8 years; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Key Selling Points: | Energy saving & Environmental; |

| Port: | Lian yun gang port/Qingdao; | After-sales Service Provided: | Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; |

| Showroom Location: | Philippines,Indonesia,Russia,Thailand,Malaysia; | Package Preview: | ; |

| Condition: | New; | Product name: | Waste tire plastic to fuel oil pyrolysis plant; |

| Place of Origin: | Henan, China; | Machinery Test Report: | Provided; |

| Warranty: | 4 years; | Oil yield: | 40%-45%; |

| Payment Terms: | L/C,T/T; | Brand Name: | Lanning; |

| Cooling system: | water cooling system; | Ending products: | fuel oil,carbon black,steel wire; |

| Supply Ability: | 200 Sets per Year; | Raw material: | waste plastic,tyre,rubber,etc.; |

| Core Components: | Pressure vessel; | Local Service Location: | Philippines,Indonesia,Russia,Thailand,Malaysia; |

| Certification: | ce,ISO,Sgs; | Warranty of core components: | 1 Year; |

| Area required: | 200-300 square meters; | Packaging Detail: | 1*40 feet HQ container small parts with wooden boxes; |

| Video outgoing-inspection: | Provided; |

Lanning small waste tyre plastic recycling pyrolysis plant to oil

1. The Raw Material For Pyrolysis Machine

|

NO. |

Raw material |

Note |

|

1 |

Waste tyre |

Steel tyre ,Nylon tyre ,Bick tyre |

|

2 |

Waste plastic |

PE,PVC,Waste washed mixture plastic from waste Paper Factory |

|

3 |

Waste rubber |

Shoes Soles,Cable Skin |

|

4 |

oil sludge,waste oil sludge |

|

|

We have our own lab to test the oil output rate of your raw material ,welcome you contact |

||

2. Pyrolysis plant models and specification

|

Product Model |

Specifications |

Per batch capacity |

Containers |

Gross weight |

Power |

|

LN-1400*4000 |

1400mm*4000mm |

1-2T |

1*40HQ |

15ton |

17KW |

|

LN-2200*6600 |

2200mm*6600mm |

5-8T |

1*40HQ+1*40FR |

26ton |

23kw |

|

LN-2800*6600 |

2800mm*6600mm |

8-10ton |

1*40HQ+1*40FR |

28ton |

25kw |

|

LN-2800*7200 |

2800mm*7200mm |

10-12T |

1*40HQ+1*40FR |

32ton |

25kw |

3.The available fuel for pyrolysis processing

|

NO. |

Fuel |

|

1 |

Oil(fuel oil, tyre oil, heavy oil etc..) |

|

2 |

Natural gas |

|

3 |

Coal |

|

4 |

Firewood |

|

5 |

Carbon black pellet |

4. End product percentage and useage( Example : raw material is tyre)

|

NO. |

Name |

Percentage |

Usage |

|

1 |

Pyrolysis oil |

40%-45% |

* can be sold directly. * make diesel and gasoline by use oil distillation machine. * can be as fuel. |

|

2 |

Carbon black |

30% |

* can be sold directly. * make fine carbon by use carbon black refining machine. * make pellet by use carbon make pellet machine. |

|

3 |

Steel wire |

15% |

* can be sold directly. * make steel bloom by use hydraulic press-packing |

|

4 |

Oil gas |

10-15% |

* can be as fuel burn by use gas burn system (pyrolysis machine included) *extra gas also be storage as fuel for other heating. |

5. Pyrolysis machine advantage and main technical characteristics

1. High oil output rate 45%--55% with special catalyst formula and high tech .

2. Rapid condensers and large cooling area,assure you get much more and higher quality oil.

diversiform cooling system can be choose according to client's willingness

3. Dust-removing device -four levels dust processing system make sure no any population and the

output smoking is the spray .more environmental protection.

4. Double tail-gas recycling and burning system, saving energy.

5. Q245R boiler plate, high temperature resistance, thickness reaches 14mm—16mm,guarantee

4-7 years service lives. and optional plate is Q345R

6. OptionalAuto feeder and carbon black discharge elevator, high automation, saving time and labors.

7. Eco-friendly and no any population, environmental protection

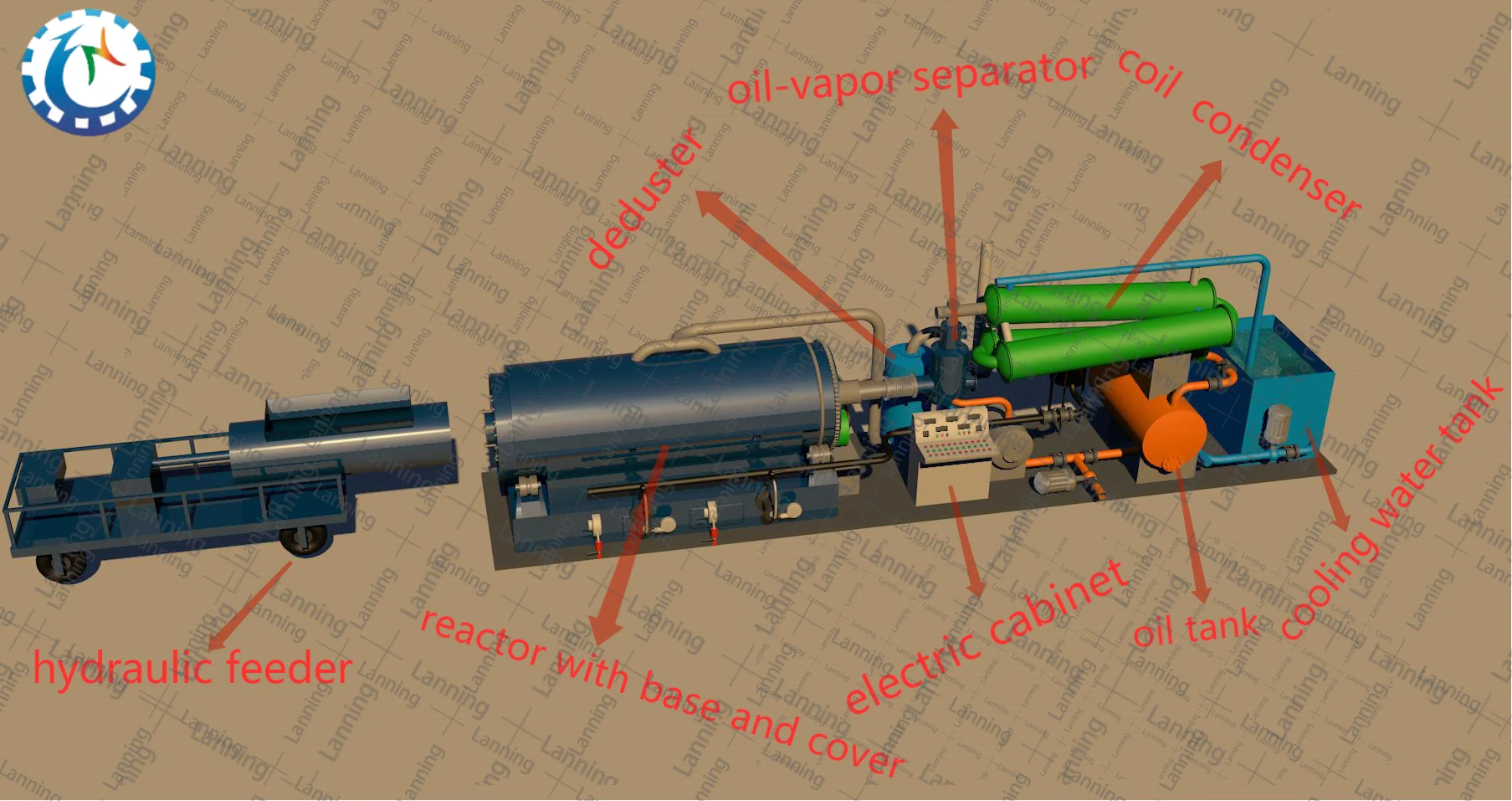

6.Machine 3D drawing flow chart and working processing

The machine can delivery within 15 working days after receiving deposit

Suitable container & shipping company will recommend to you to save shipping fee.

Installation

1) History:

Founded in 2006 with Ningling Lanning Technology Co.,LTD.

Renamed in 2017 by Henan Lanning Technology Co.,LTD

2) Location:

Located in Ningling county, Shangqiu city, Henan province, China.

3) Main Products:

Tyre/ Plastic Pyrolysis machine;

Oil distillation machine;

Carbon black make pellet machine;

4) Certification:

ISO 9001

SGS (Societe Generale de Surveillance)

CE (International exports to the European Union certification)

BV (French authority certification)

TUV (Germany authority certification)

About Guarantee & after service

All the various series of the equipment we sell enjoy perfect after -sale service :

1. We will send engineers to help you with the installation of the machine and the training of your

workers until everything runs smoothly.

2. We guarantee the complete machine one year since installation. If during the first year, there is any

problem caused by the machine quality, we take responsibility.

3. We guarantee the reactor life more than 6 years, other parts no need change expect the vulnerable

parts .

4. We provide the whole life machine maintenance. we will try our best to solve the customers' extra worries.

Let's mutual reciprocity and benefit, win-win hand in hand