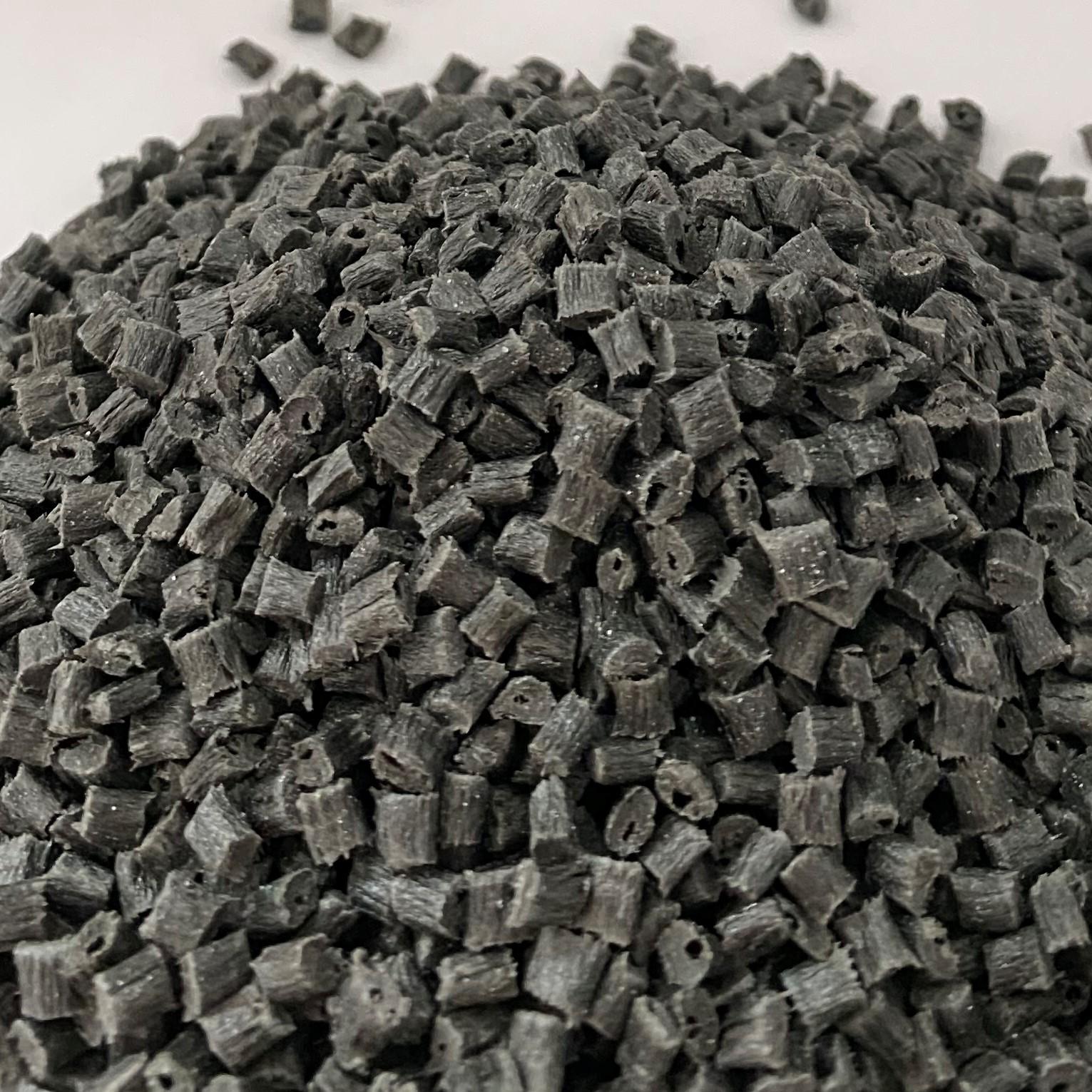

Modified engineering plastic 40% glass fiber content high rigidity wear-resistant conductive PPS particles

- $5.00 / >=1000 kilograms

- 1000 kilograms

- Tensure (dalian) Advanced Polymer Co., Ltd.

- Liaoning, China

- Ms Caroline Cao

PRODUCT DETAIL

| sample: | available | port: | Dalian Port |

| color: | custom made | payment terms: | L/C,T/T,Western Union |

| Minimum order quantity: | 25kg | Filler content: | 40% glass fiber |

| Non-flammable: | UL94 V0 | pack: | 25kg |

| Supply capacity: | 5000 tons/month | brand: | tension |

| place of origin; place of origin: | Liaoning, China | grade: | Injection grade. Extrusion grade |

| feature: | 30%/40% glass fiber reinforced | model: | TS9040LC |

| application: | electronic product |

Product Description

Company Profile

TESURE(DALIAN) Advanced Polymer Co.,ltd was founded in July 2014 by a number of experts in the field of new materials. Tianshu is committed to providing customers with a complete set of material solutions to help customers provide solutions in the field of new materials in their industry growth and innovation. In 2015, Tianshu passed the ISO9001 quality management system certification and ISO14001 environmental management system certification. The company's products mainly focus on customized high-performance modified materials, including modified engineering plastics (such as PC, PBT/PET, PA6, PA66, PPA, etc.), modified special engineering plastics (such as high temperature nylon, PPS, PEEK, PEI) and Special functional materials (electrical, thermal, magnetic response, 5G applications, etc.).

Company mission

Company mission

With our knowledge, experience and capabilities in new materials science, we help our customers grow and innovate across industries to create safer, better lives for people.

company core value

company core value

Safety and environmental protection, respect for others, honesty and trustworthiness, cooperation and innovation.

Specification

Typical value at 23°C | unit | standard test | TS9040LC | |||

characteristic | ||||||

symbol | - | ISO 1043 | PPS+40%GF | |||

density | g/cc | ISO 1183 | 1660 | |||

23℃, 24h saturated water absorption | % | ISO 62 | 0.02 | |||

Mechanical behavior | ||||||

tensile strength, fracture | MPa | ISO 527 | 190 | |||

Tensile elongation, break | % | ISO 527 | 1.6 | |||

Flexural modulus | grade point average | ISO 178 | 14.5 | |||

Flexural strength | MPa | ISO 178 | 280 | |||

friction coefficient | - | - | - | |||

Shear strength | MPa | day mark | - | |||

Human Rights Commission | - | ISO 203 | - | |||

L | mg/10 | ISO 935 | - | |||

CHARPY Impact Strength, Izod | kJ/square meter | ISO 179 | 9.5 | |||

CHARPY Impact Strength+23℃ | kJ/square meter | ISO 179 | 55 | |||

Thermal performance | ||||||

Melting point, DSC | °C | ISO 1133 | - | |||

1.8Mpa HDT under load | °C | ISO 75 | 260 | |||

CLTE (traffic) | 10-5/thousand | ISO 11359 | 2.3 | |||

CLTE (vertical) | 10-5/thousand | ISO 11359 | 3.5 | |||

flammable | ||||||

UL standard | grade class | UL 94 | V=0 | |||

Electrical properties | ||||||

1MHZ dielectric constant | - | IEC 60250 | - | |||

Dissipation factor at 1 MHZ | 10-4 | IEC 60250 | - | |||

Volume resistivity | Ω.cm | IEC 60093 | 1014 | |||

Withstand voltage | - | IEC 60243 | twenty four | |||

statement statement | ||||||

These data can only be used as classical values. is not identified as an index or unless expressly agreed in writing Guaranteed material value. Mold/head design and processing have a certain impact on product performance Condition and coloring. All data are from tests performed on standard samples at room temperature unless otherwise stated. | ||||||

exhibition

our competitive advantage

First-class advantage

custom madeCoperion, Germanyextrusion system.

imported fromSwitzerlandEstablish a weightless feeding system.

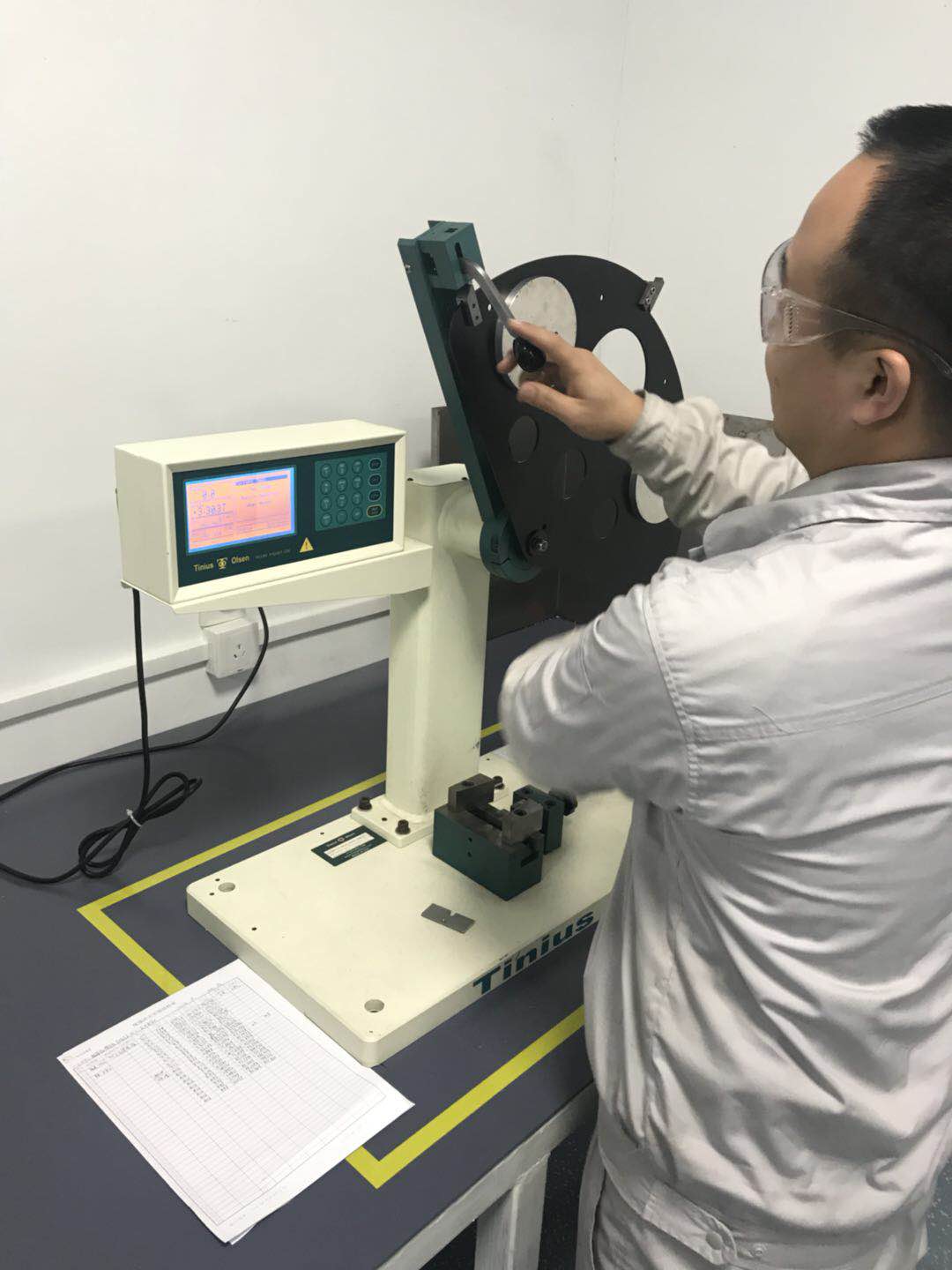

AmericanTinius OlsenLaboratory testing equipment.

custom madeCoperion, Germanyextrusion system.

imported fromSwitzerlandEstablish a weightless feeding system.

AmericanTinius OlsenLaboratory testing equipment.

To ensure the stability of production quality and the realization of the process.

excellent team

Technical R&D Director

Returned Ph.D. in the field of new materials. He used to be a scientist in the China R&D Center of a foreign-funded material company. He led the development of a number of product patents and has rich experience in R&D management.

Factory Operations Director

With many years of experience in factory operation and management, he was responsible for the implementation and management of investment and expansion of foreign material manufacturers' Chinese factories.

Marketing Operations Director

Head of the strategic planning of the foreign-funded China headquarters, and head of the Chinese market of a foreign-funded material company. He has extensive experience in market management and business application development.

Technical R&D Director

Returned Ph.D. in the field of new materials. He used to be a scientist in the China R&D Center of a foreign-funded material company. He led the development of a number of product patents and has rich experience in R&D management.

Factory Operations Director

With many years of experience in factory operation and management, he was responsible for the implementation and management of investment and expansion of foreign material manufacturers' Chinese factories.

Marketing Operations Director

Head of the strategic planning of the foreign-funded China headquarters, and head of the Chinese market of a foreign-funded material company. He has extensive experience in market management and business application development.

Product packaging

VIEW MORE

YOU MAY LIKE