New frozen French fries and potato chips processing machinery production line potato chips making machine

- $15000.00 / 1 - 1 sets

$13000.00 / 2 - 4 sets

$7000.00 / >=5 sets - 1 set

- Henan Joyshine Machinery Co., Ltd.

- Henan, China

- Mr

PRODUCT DETAIL

| Mechanical function: | Potato chips and fries production line | application: | Snack food production line |

| Dimensions (L*W*H): | 5500*2000*2000mm | Main selling point: | high productivity |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram | Accessories: | Fuel tank and extra oil |

| strength: | 10KW | brand: | happy hour |

| Voltage: | 220V/380V | Supply capacity: | 20 sets per month |

| port: | Shanghai, Qingdao | thing: | industrial potato chips |

| Packaging Details: | New frozen French fries and potato chips processing machinery production line 1. Our company usually adopts standard export wooden box packaging. 2. By sea, train, express or according to customer requirements. | feature: | High-efficiency potato chip production line |

| Marketing Type: | New Products 2020 | weight: | 200kg |

| Warranty: | 1 year | Showroom location: | Egypt, Canada, United States, Italy, Vietnam, Philippines, Peru, Mexico, Russia, Thailand, Morocco, Kenya, South Korea, Chile, Algeria, Romania, South Africa, Nigeria, Uzbekistan, Malaysia, Australia |

| type: | Fully automatic processing line | Heating type: | Gas or Electric |

| Raw materials: | fruits, vegetables, water | After Warranty Service: | Video technical support |

| Mechanical test report: | if | Output product name: | Potato Chips Processing Machinery |

| capacity: | 50-2000kg/hour | place of origin; place of origin: | Henan, China |

| Applicable industries: | Hotel, Food and Beverage Factory, Restaurant, Household, Food Store, Food and Beverage Store | Core Components Warranty: | 1 year |

| Video external inspection: | if | Application areas: | Vegetable Processing Plant, Commercial Catering, Fruit Processing Plant, Frozen Food Plant |

| Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

Product Description

We are a professional direct manufacturer of potato chips or french fries making machine in China.

we have different solutionsDifferent requirements:

1: Different machines for making chips or french fries

2: Small, medium and large capacity from 30kg/h, 50kg/h, to 100kg/h, 300kg/h, to 1000kg/h, 2000kg/h The output and workflow can be customized

3: Semi-automatic or fully automatic processing machine

4: Electric or gas, diesel heat source is used for blanching the fryer.

5: The size of the fries and the thickness of the chips are adjustable.

6:For the french fries production line, we have special equipment to remove unqualified fries.

7: All machines use SUS304, Schneider electric components and Siemens brand motors.

8: Specially designed fryer, fast heating, energy saving and good performance

Fully automatic frozen French fries production process:

Do not. | Machine name | Function |

1 | PVC elevator | For lifting and transporting fresh potatoes to the next washing and peeling machine |

2 | potato cleaning and peeling machine | Thoroughly wash and peel potatoes |

3 | Sorting conveyor | For manual handling of uncleaned areas and selection of defective potatoes |

4 | french fries cutter | Cut potatoes into fries, the size is adjustable from 7*7 to 12*12mm |

5 | water tank lift | Water acts as a buffer, preventing fries from breaking and simply removing starch while lifting fries to the next step |

6 | French fries sorting machine | Automatically pick up small pieces of fries |

7 | Bubble cleaning machine | Shock and scrub the fries with high pressure water jets and blisters to wash away the starch |

8 | blanching machine | By scalding hot water at 60-95 degrees, the activity of enzymes is inhibited and the original bright color of the fries is maintained |

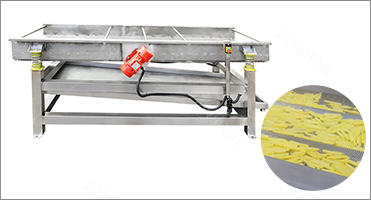

9 | Vibrating dehydrator | Vibration to remove surface moisture and evenly transport the fries to the next machine |

10 | air dryer | Pre-cooling is carried out by high-pressure air blowing, and excess water is removed in a short time, effectively preventing the phenomenon of frying oil jumping |

11 | Lifting conveyor | For lifting and conveying fries to the next fryer |

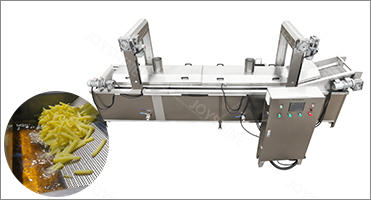

12 | continuous fryer | For quick frying potatoes in 180° oil for about 40 seconds to avoid sticking and extend shelf life |

13 | Vibration degreaser | Degrease is achieved by vibration, while the fries are evenly transported to the next machine |

14 | Precooler | Pre-cooling and degreasing the fries by high pressure air blowing |

15 | freezer | The fluidized quick freezer floats the product on the stainless steel mesh belt through mechanical vibration and wind pressure, freezes the product and prevents sticking, and realizes quick freezing |

16 | Automatic packaging machine | For packaging finished frozen fries |

Detailed description

Raw Potatoes PVC Elevator

potato cleaning and peeling machine

Unqualified potato sorting conveyor

potato cutter

french fries slicing

water tank lift

French fries sorting machine

Bubble cleaning machine

blanching machine

Vibrating dehydrator

air dryer

elevator conveyor

continuous fryer

Vibration degreaser

Air cooler

IQF Freezer Tunnel

Automatic weighing packaging machine

It is suitable for processing workshops such as large and small potato chips, banana chips, etc. We can formulate suitable solutions according to your workshop area and your actual situation!

about us

We can provide one-stop turnkey projects with industry-leading technology and R&D team as the front end, production and processing teams headed by more than 10 years of skilled workers as the mid-end, almost strict quality inspection standards, and professional after-sales team on-site Install.

facility:There are 12 shearing equipment, 48 argon arc welding auxiliary equipment, shearing machine, cutting machine, electric welding machine, gantry crane and drilling equipment.scale:The workshop covers an area of 15,000 square meters and has 10 production lines.

We have more than 20 years of design and development team, 12 product patents, can be customized according to the needs of different customers

Our company's production capacity can meet the spot inventory. One of the independent warehouses covers an area of more than 2,000 square meters, which can quickly provide customers with complete sets of production line equipment.

VIEW MORE

YOU MAY LIKE

Other Products

-

Commercial Ozone Fruit And Vegetable Washer Cleaning Bubble Carrot Cassava Apple Washing Machine$3900.00 - $8800.00 / set

Commercial Ozone Fruit And Vegetable Washer Cleaning Bubble Carrot Cassava Apple Washing Machine$3900.00 - $8800.00 / set -

Commercial Ozone Fruit And Vegetable Washer Cleaning Bubble Carrot Cassava Apple Washing Machine$3900.00 - $8800.00 / set

Commercial Ozone Fruit And Vegetable Washer Cleaning Bubble Carrot Cassava Apple Washing Machine$3900.00 - $8800.00 / set -

frozen french fries machinery 100kgh semi automatic french fried production line$8800.00 - $16800.00 / set

frozen french fries machinery 100kgh semi automatic french fried production line$8800.00 - $16800.00 / set