Quality 1 Ton Tyre Pyrolysis Waste Get Oil Recycling Plant Crude Oil Machine

- $36500.00 /set

- 1 set

- Shangqiu Xieli Environmental Protection Technology Co., Ltd.

- Henan, China

- Ms Tina Zhou

PRODUCT DETAIL

| Core Components: | PLC,Engine,Gearbox,Motor,Gear,Pump; | Marketing Type: | New Product 2021; |

| Supply Ability: | 10 Sets per Month; | Warranty: | 2 years; |

| Place of Origin: | Henan, China; | After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; |

| Package Preview: | ; | Payment Terms: | L/C,T/T; |

| Port: | Shanghai Port,Lianyungang Port,Qingdao Port; | Modle: | TN-2800*7500; |

| Showroom Location: | Turkey,Indonesia,Bangladesh,Uzbekistan,Malaysia; | Power: | 25KW; |

| Reactor Thickness: | 16mm; | Applicable Industries: | Manufacturing Plant,Energy & Mining,Waste Plastic Recycling; |

| Pressure: | 0.03Mpa; | Brand Name: | XIELI; |

| Machinery Test Report: | Provided; | Function: | Convert Waste Plastic to Fuel Oil; |

| Weight (KG): | 38000 KG; | Local Service Location: | Turkey,Viet Nam,Philippines,Indonesia,Kazakhstan,Ukraine,Uzbekistan,Tajikistan; |

| Capacity: | 5TPD, 6TPD,8TPD,10TPD,12TPD,15TPD; | Video outgoing-inspection: | Provided; |

| Condition: | New; | Key Selling Points: | Energy saving; |

| Warranty of core components: | 2 years; | Output: | 45% Oil; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Final Product: | Plastic Oil, Carbon Black; |

| Advantage: | Environmental-friendly; | Application: | Waste Tyre, Waste Rubber, Waste Leather, Waste Plastic; |

| Packaging Detail: | 1 pc*40FR+2pc *40HQ; |

PRODUCT SPECIFICATIONS

Product Name | Waste Plastic Pyrolysis To Fuel Oil Equipment | ||||||

Capacity | 5TPD, 6TPD, 8TPD, 10TPD, 12TPD, 15TPD,50TPD | ||||||

Reactor Material | Q345R, Alloy Steel, Stainless Steel | ||||||

Reactor Thickness | 16.45mm, 18.45mm | ||||||

Total Weight | 30-40 tons (Varies by Design and Capacity) | ||||||

Working Power | 15-30KW(Varies by Design and Capacity) | ||||||

Labor Qty Require | 2-4 Persons for per set machine, more machine, fewer labors | ||||||

Processing Time | Feeding 2 Hours, Processing 8-9 hours, Carbon Black and Steel Wire Discharging 1.5 hours. (Take 12TPD capacity as example) | ||||||

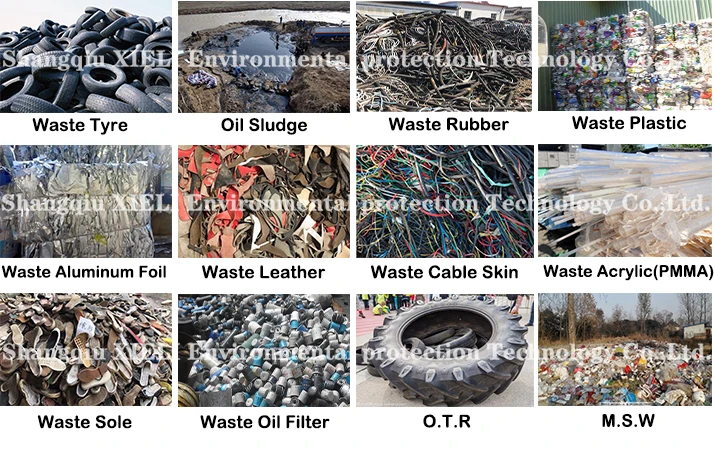

Application Material | Waste Tyre, Waste Rubber, Waste Plastic, Waste Oil Sludge, Waste Aluminum Foil, Waste Cable, Waste Leather, Waste Acrylic(PMMA),etc... | ||||||

Heating Fuel | Pyrolysis Oil, Natural Gas, Electricity, Coal, Firewood, etc... | ||||||

1) Raw Material Can be Used In Pyrolysis Machine

2) Final Production and Usage

20-80% Plastic Oil

12-72% Carbon Black

No. | Output Name | Output Yield | Usage |

1 | Plastic Oil | 20-80% | * Sell directly. * Further refining to get standard diesel and gasoline via Xieli distillation machine. * Use as fuel for heating pyrolysis machine or distillation machine. |

2 | Carbon Black | 12-72% | * Sell directly. * Further Refine carbon via carbon black refining machine. * Make pellet via carbon pellet maker. |

4 | Syn Gas | 6-7% | * Recycle as fuel through gas burner system(we supply gas burner for free). * Extra gas also can be storage as fuel for other heating. |

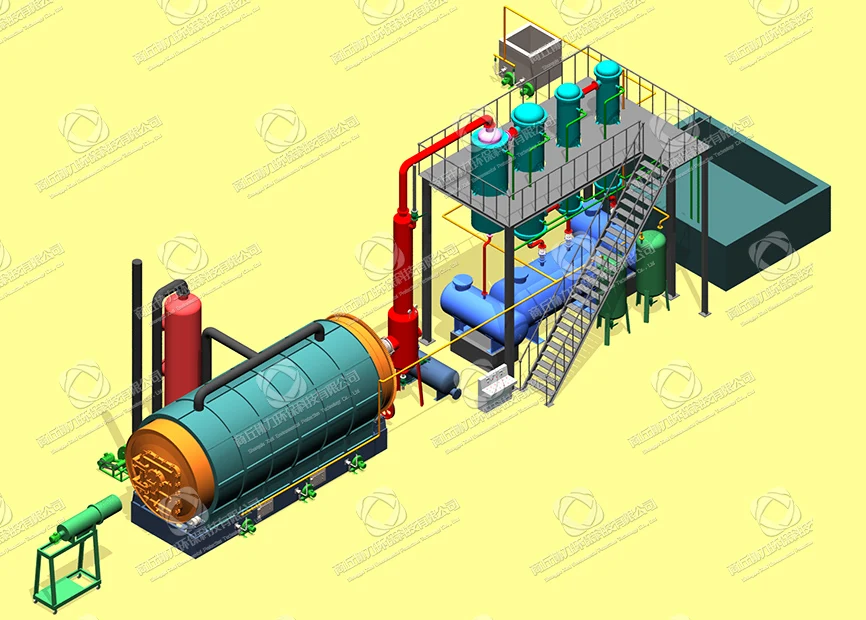

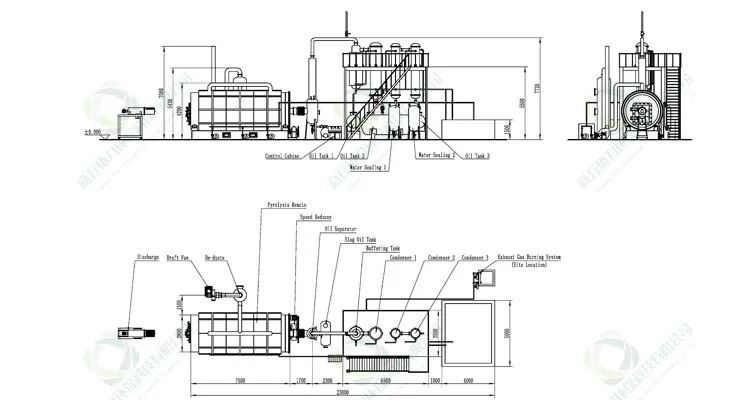

3) Layout Drawing

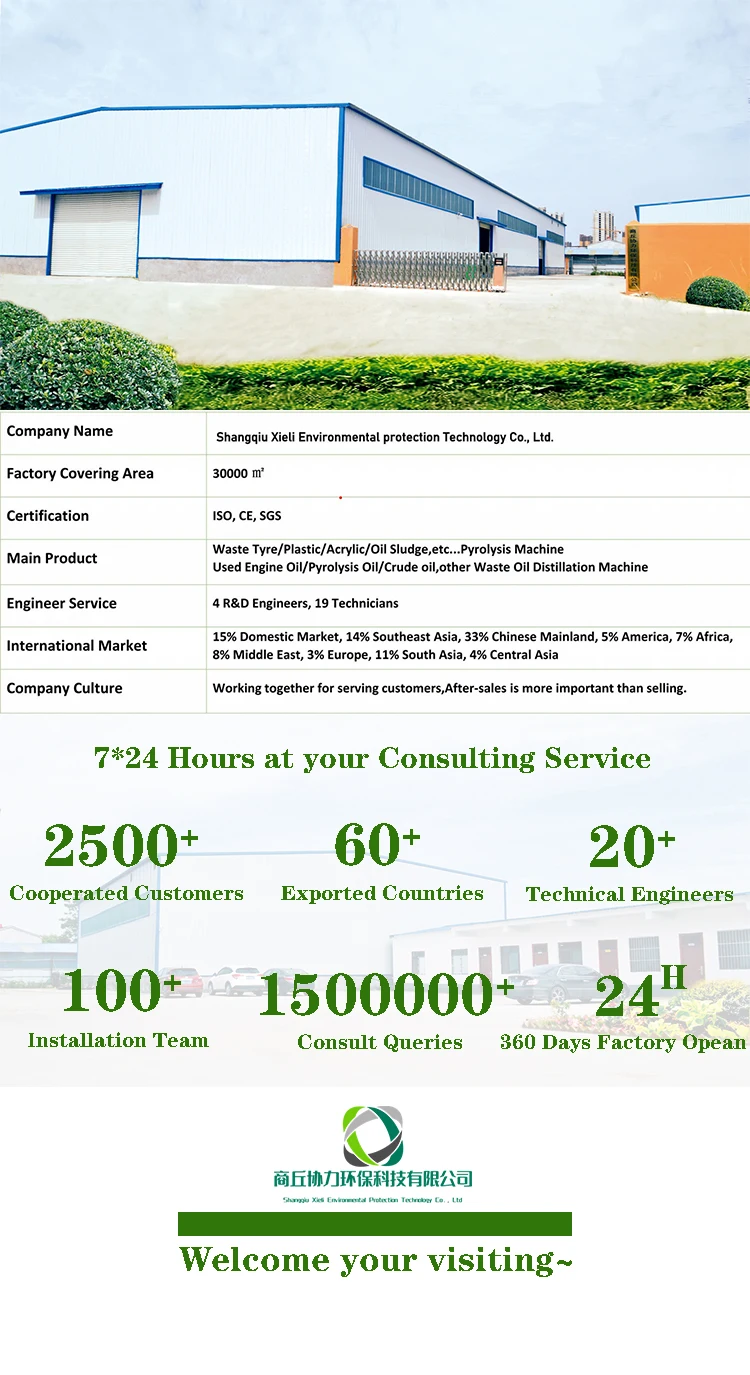

Company Profile

Why Choose Us

Machine Durable Using and High Efficiency Manufacturing Technology | ||||||||

Reactor material | Adopt high pressure and temperature resistance steel plate to ensure longer service life. For some speical raw material , we use special steel plate | |||||||

High efficiency discharging | Adopt screw converyor discharging device , discharge carbon black in sealed condition , no pollution and save labour and time . | |||||||

Integrated condensing device | All of the condensing parts have been installed together before delivery from factory , save installation time and ensure welding quality | |||||||

Labour Saving | Auto feeder machine to feed raw material automatically , save labour and time. | |||||||

Motor & Valve | All of the motors can be customized.All of the valves use stainless steel. | |||||||

Non pollution | Adopt 3 layers of ceramic packing dedusting device and water spray , finally no black smoke discharged out. SGS emission report provided. | |||||||

Safety devices | Alarm , auto pressure releasing device , and anti back fire device , vacuum pump to ensure the machine working smoothly. | |||||||

After-sale Service

Pre-Sale Service

Design and manufacture machines for you as your special requirements, provide you with project, process design, and purchase

programm.

programm.

On-Sale Service

Accompany with you to look around our factory, explain the manufacture process of our machines, and check the quality of our

machines

machines

After-Sale Service

Engineers are available to install and debug equipments of the whole production line, besides, training operators on site.

Successful Project

Our Machine has been served for more than 1000 customers, running life at least 5 years, after 5 years running, you can only replace the reactor with new is Ok, other parts you can use at least 10 years, so we provide the durable machine to your end.

Shipping

Delivery our machine to more than 60 countries

Since 2008, we have exported our Pyrolysis machine and distillation machine to more than 63 countries, but every customer buy from us all get our best service and we send most professional engineer installation guidance,commissioning and training customer workers, we will not leave until customer can operate machine without any problem. We are always here waiting for cooperating with you, welcome query 24 hours!

FAQ

Q1 | Can we process mixed material of tire and plastic? | ||||||

A1 | We don't suggest that working, because their pyrolysis temperature different, if mix, will waste your heating energy. | ||||||

Q2 | Is XL-20 Pyrolysis Plant a BATCH system? | ||||||

A2 | No, semi-continuous with pretreating system | ||||||

Q3 | Also can this plant take all types of waste plastic? | ||||||

A3 | Except PET and PVC, the rest can be deal with. | ||||||

Q4 | What's the advantage of " Three in one"? | ||||||

A4 | Oil tank, oil condenser,hydraseal Save installation time and land; with good cooling effect | ||||||

Q5 | Does the reactor use the burnable gases generated by the pyrolysis process as additional fuel to heat the reactor? | ||||||

A5 | Yes.The combustible gas generated during the pyrolysis process after the hydroseal desulfurization and imputoty removal, can be used as fuel heating the reactor. | ||||||

Q6 | Are there other locations. I saw an office in Canada. Is that correct? | ||||||

A6 | We have set up branches and overseas warehouses in Russia, Pakistan and Uzbekistan. | ||||||

VIEW MORE

YOU MAY LIKE