Stainless Steel FPCG-10 Granulator Pharmaceutical Granulator

- $25000.00 /unit

- 1 unit

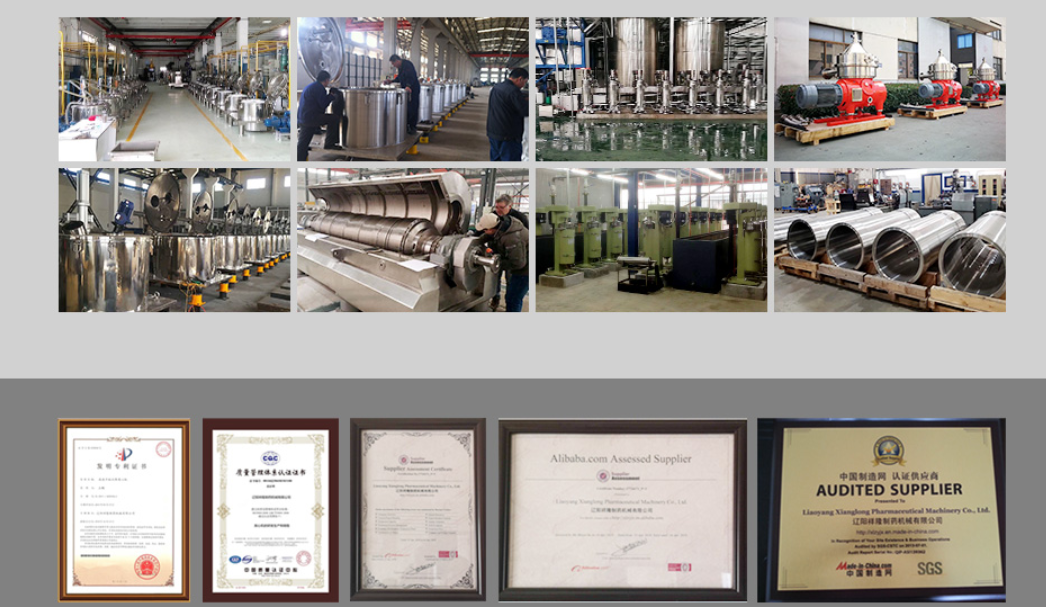

- Liaoyang Xianglong Pharmaceutical Machinery Co., Ltd.

- Liaoning, China

- Mr MR ZHENG

PRODUCT DETAIL

| Video external inspection: | if | Supply capacity: | 20 units per month |

| After-sale service: | On-site training and debugging | Control System: | PLC control |

| Loading capacity: | 1.5-150kg/batch | application: | medicine, powder |

| Main selling point: | long lasting | Key words: | Pill coating |

| brand: | extra large | payment terms: | letter of credit, wire transfer |

| Applicable industries: | Pharmaceutical, food industry, chemical industry | Health status: | new |

| place of origin; place of origin: | Jiangsu, China | Marketing Type: | New Products 2020 |

| Operation: | batch processing | type: | Powder granulation, granulation, coating machine |

| Warranty: | 1 year | Weight (kg): | 800kg |

| Mechanical test report: | if | Showroom location: | not any |

| Material: | SUS304/316 | Packaging Details: | Wooden export box, fumigation-free composite board |

| Packaging Preview: | port: | Dalian, China | |

| Dimensions (L*W*H): | 1500*950*2300mm | Power (kW): | 6-9kW |

| Core Components Warranty: | 2 years | product name: | Powder Granulating Dryer |

| Voltage: | 380V / 240V | Core components: | PLC, engine, motor, pressure vessel, pump |

Excellent stainless steel raw materials

Granulation, coating, drying series equipment

The work of this machine:

GHL Wet Mixer Granulator

The machine adopts the horizontal cylinder structure, the structure is reasonable, the air-filled sealed transmission shaft can be switched to water when cleaning. Fluidized granulation, the granulation is approximately spherical, and the fluidity is good. 25% less binder than traditional process, short drying time, 2 minutes dry mix per batch. The granulation takes 1-4 minutes, which is 4-5 times higher than the traditional process.

Wet and dry mixing in the same airtight container - granulation, process reduction and GMP compliance. The entire operation has strict safety protection measures.

● Pharmaceutical industry: tablets, capsules, low-sugar or sugar-free Chinese medicine granules.●Food: cocoa, coffee, milk powder, granular juice, flavoring agent, etc.●Other industries: pesticides, feed fertilizers, pigments, dyes, etc.●Pharmaceutical industry: powdery or granular materials.

Advantages of this machine:

● GMP standard, easy to clean - the inner surface of the equipment is smooth to avoid dead corners.

● Suitable for heat-sensitive materials - suitable for room temperature -100 ℃.

● HMI digital chart control system - automatic operation procedures, reduce labor intensity.

● Use air as power to avoid environmental pollution caused by leakage of smoke liquid when liquid is used as power.

● WIP/CIP automatic cleaning device, pulse dust removal, anemometer, powder leak detector, suction device, vacuum unloading device, unloading overturning device, pressure 2bar explosion-proof type optional.

● Negative pressure work, the material is easy to dry.

● Multifunctional——Complete the process of mixing, spraying, granulating, drying and other materials in a closed container at one time.

● HMI digital chart control system - automatic operation procedures, reduce labor intensity.

● Use air as power to avoid environmental pollution caused by leakage of smoke liquid when liquid is used as power.

● WIP/CIP automatic cleaning device, pulse dust removal, anemometer, powder leak detector, suction device, vacuum unloading device, unloading overturning device, pressure 2bar explosion-proof type optional.

● Negative pressure work, the material is easy to dry.

● Multifunctional——Complete the process of mixing, spraying, granulating, drying and other materials in a closed container at one time.

Mainly used for drying, granulation and instant granulation.

Mainly used for ordinary film coating, sustained-release and controlled-release coating, enteric coating, coating of pellets/pellets, powders, seeds, and granules.

It is mainly used in the production of granulation, granulation and coating, which is beneficial to the granulation of granules, and has a smooth surface, which is an ideal choice for making capsules.

Wooden export box, fumigation-free composite board, or according to customer requirements.

Project cases

FPCG-15 fluidized bed granulation coating machine

LGX-160 Dry Granulator

CC5 high-level feeding granulation drying production line

NTD-300 Hopper Lift Feeder

CCS-30 Vacuum Feeding Granulation Drying Line

SMG-200 Advanced Wet Granulator

How to choose the right machine? | Fluidized bed series dryers can be customized. Before we make a detailed quote, we need to know some simple information: 1) The product needs to be processed 2) Before and after moisture information or particle characteristics 3) Daily production capacity per kg/batch 4) Heat source |

Can you guarantee that the machine is working properly? | If feasible, we will provide sample material testing and provide factory site commissioning until it works properly. |

Can you provide after-sales service? | We will arrange engineers for overseas installation and on-site commissioning. In addition, we will also arrange training how to Install the machine and how to use it. |

How long is the warranty period? | Mechanical body is 1 year. Online consultation support is always available. |

pre-sale service

1. Ensure the high quality of new products before delivery.

2. Packed according to export requirements and shipped carefully.

3. Provide a full set of documents according to customer requirements.

4. Free spare parts for one year.

5. On time delivery.

2. Packed according to export requirements and shipped carefully.

3. Provide a full set of documents according to customer requirements.

4. Free spare parts for one year.

5. On time delivery.

After-sales service

1.Support equipment installation and debugging, and can send technicians to go abroad for service.

2. Provide 24-hour technical support by email or phone.

3. Spare parts are sufficient.

4. Help customers with any other questions about the product or otherwise.

2. Provide 24-hour technical support by email or phone.

3. Spare parts are sufficient.

4. Help customers with any other questions about the product or otherwise.

Commitment to Service

1. We will provide a 1 year warranty to ensure the machine runs consistently. Maintain a certain level of spare parts inventory to ensure that spare parts replacements are delivered as quickly as possible

2. Technical service for the life of the whole machine, and online support can also be provided.

3. We will arrange engineers to your workshop to guide installation and machine debugging, and train operators until the machine runs normally.

2. Technical service for the life of the whole machine, and online support can also be provided.

3. We will arrange engineers to your workshop to guide installation and machine debugging, and train operators until the machine runs normally.

VIEW MORE

YOU MAY LIKE

Other Products

-

Factory Price High Efficiency Bgb Series Dressing Machine$1650.00 / set

Factory Price High Efficiency Bgb Series Dressing Machine$1650.00 / set