cassava starch machinery cassava starch machine capacity cassava starch processing

- $500.00 /set

- 1 set

- Zhengzhou Hanchuang Machinery Co., Ltd.

- Henan, China

- Mr

| Port: | Qingdao, Shenzhen and other ports required by customers; | Power: | 2.2kw,2.2kw; |

| Condition: | New; | After Warranty Service: | Video technical support,Online support; |

| capacity: | 500-700kg/h; | Warranty: | 1 Year; |

| After-sales Service Provided: | Online support; | Brand Name: | hanchuang; |

| Applicable Industries: | Hotels,Food & Beverage Factory,Farms,Restaurant,Home Use,Food Shop,Food & Beverage Shops; | Packaging Detail: | Uniform use of wooden box packaging, if the customer has other needs, can be packaged according to customer requirements.; |

| Place of Origin: | China; | Video outgoing-inspection: | Provided; |

| Payment Terms: | Western Union,T/T,MoneyGram; | Features: | easy to use; |

| Warranty of core components: | 1 Year; | whatsAPP: | +8613525551927; |

| Machine weight: | 30kg (without motor); | Marketing Type: | New Product 2020; |

| Spindle speed: | 2000r/min; | Voltage: | 220v/380v,220v; |

| Dimension(L*W*H): | 820*340*970mm; | Residue powder rate: | ≥2%; |

| Machinery Test Report: | Provided; | size: | 700*400*380mm; |

| Motor speed: | 2800r/min; | Production Capacity: | 500-700kg/h; |

| Core Components: | Motor; | Filter: | 80 mesh; |

| Showroom Location: | None; | Application: | Potato starch processing; |

| Local Service Location: | None; | Supply Ability: | 50 Sets per Month; |

cassava starch machinery cassava starch machine capacity cassava starch processing

whatsAPP:+8613525551927

The starch separator is easy to operate, stable in operation, high in productivity and easy in maintenance. It can complete the three processes of coarse crushing, fine grinding and pulp residue separation of fresh potatoes at one time, which can reuse the slurry and reduce the wastewater in the starch production process. Changed the phenomenon of starch color deterioration and darkening caused by oxidation during the manual production of starch; the powder residue crushed during processing was filamentous under the microscope, which was conducive to the release of starch from the fiber, thereby improving the starch Extraction rate.

The potato starch separator can process sweet potatoes, potatoes, yam and other potatoes into starch at one time, then extract the starch, separate the pulp residue, and then use it as vermicelli, vermicelli, or starch to process other products again, which can also be called Sweet potato starch machine, potato starch separation machine. A kind of potato flour milling equipment developed and produced that is suitable for scattered processing and use of farmers and has a relatively small investment. It is suitable for processing potatoes, sweet potatoes, cassava, dried sweet potatoes and other potatoes; banana root, kudzu root, lily , Yam and other tuber plants are ideal equipment for starch processing enterprises, vermicelli processing enterprises, farmers and other potato starch processing potatoes and potatoes.

Product Detail Data

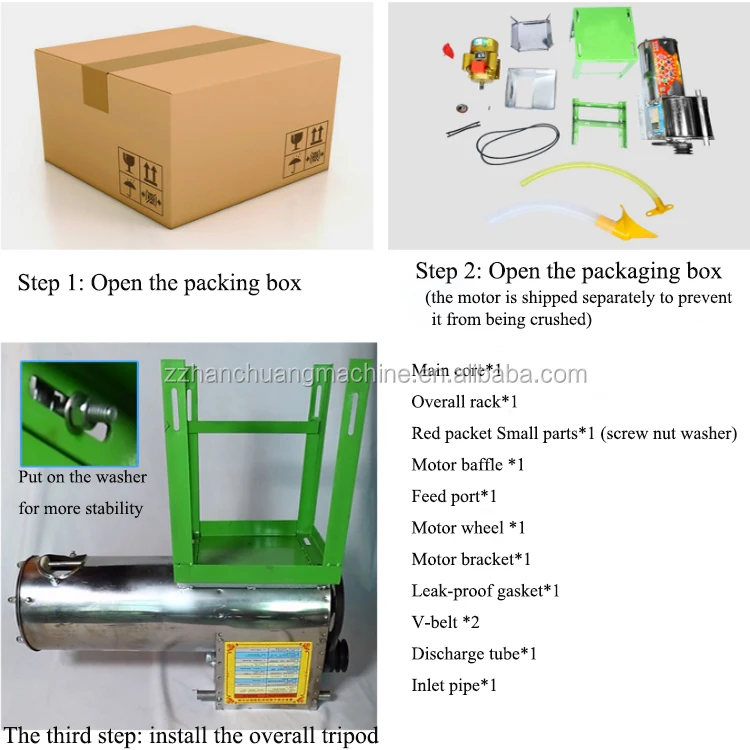

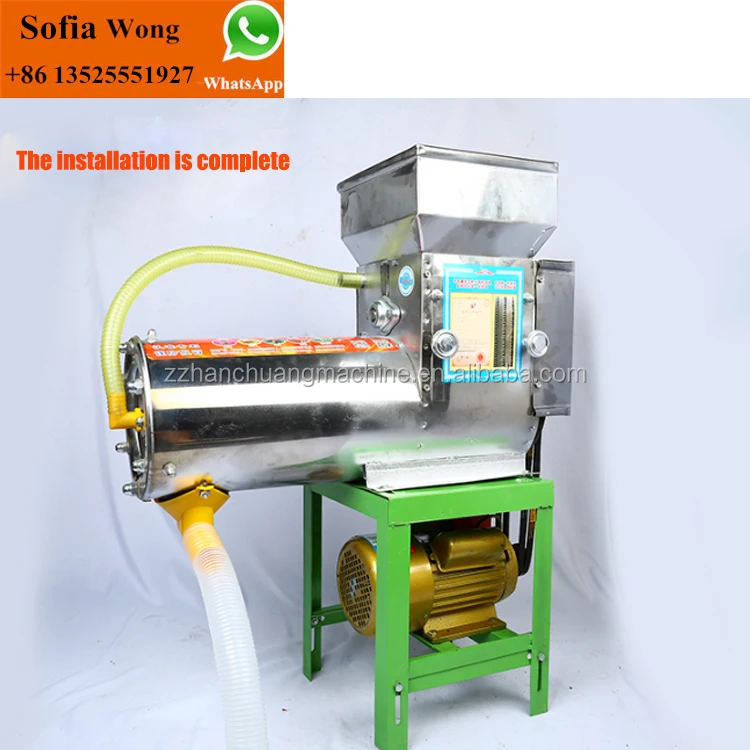

installation steps

Packaging & Shipping

1. Testing Machine before package

2. Package : Inside plastic bag, outside wooden case.

3. Shipping: By sea, By air.

By sea: if customer not urgently the machine, we advice by sea, even though by sea took time is long, but by sea reduce much money about the freight, and it is good for customer if the machine is heavy and big size.

By air: it is faster than by sea, but its freight is higher much than by sea, so this kind of type always suggest for light, small size and urgently demand machine.

Pre-sale service

1.Related machines’s technical parameter will be supplied to customer.

2.According to customer’s factory size, factory layout can be provided in advance.

3. According to customer’s material cost, general formulation can be prepared well.

4.Special machine can be supplied as customer’s request.

5.Professional Advice about Market, machines, processing , materials, packing can be supplied

6. Suggesting professional ship agent or helping book ship as customer request.

After sale service:

1.Allocation chart as the buyer’s request will be supplied.

2.Operation manual will be supplied after shipment.

3.One year warrantee, life time maintenance with cost price.

4.Free easy broken spare parts will be sent with container .

5.First installation can be done by engineer.

6.Training workers in customer’s factory.

Contact Person

If you had any problem, just feel free to contact with us.

Any time, we will reply you as soon as possible!