10KW Portable Induction Heating Machine for Copper Pipe Welding

- $1.00 /set

- 1 set

- Zhengzhou Daqing Automation Equipment Co., Ltd.

- Henan, China

- Ms Mandy Sheng

PRODUCT DETAIL

| Package preview: | Machine name: | Induction Heating Equipment | |

| Type of machine: | induction heating machine | Showroom location: | not any |

| payment terms: | L/C, T/T | Weight (kg): | 45 |

| Health status: | new | MOQ: | 1 set |

| brand: | De Q Automobile | Mechanical test report: | if |

| Packaging Details: | Standard packing in plywood carton to ensure proper protection during delivery. If necessary, we will pack according to customer's special requirements. | Core component warranty: | 1 year |

| Origin: | Henan, China | Advantage: | Easy to operate, small in size and light in weight |

| Input Current: | 18A | Video outbound inspection: | if |

| Warranty: | 1 year | Input voltage: | Three-phase 380V 50-60Hz |

| Continuous output power: | 10 kW | port: | Chinese ports, Shanghai, Qingdao, etc. |

| Cooling water pressure/water flow: | 4-8 bar 2 l/min | Main selling points: | easy to operate |

| application: | Brazing copper tubes, pipes, splitters, steel tubes, aluminum tubes | Output frequency: | 20-50KHZ |

| Marketing Type: | Hot Products of 2019 | Applicable industries: | Mechanical repair shops, manufacturing plants, food and beverage plants, construction, energy and mining, other |

| Supply capacity: | 1000 sets per week | product name: | induction heating machine |

| Core components: | PLC, bearings, motors, pressure vessels, pumps |

Portable Handheld 10KW Induction Heating Machine for Copper Tube Welding

product description

product specification

successful project

Recommended Products

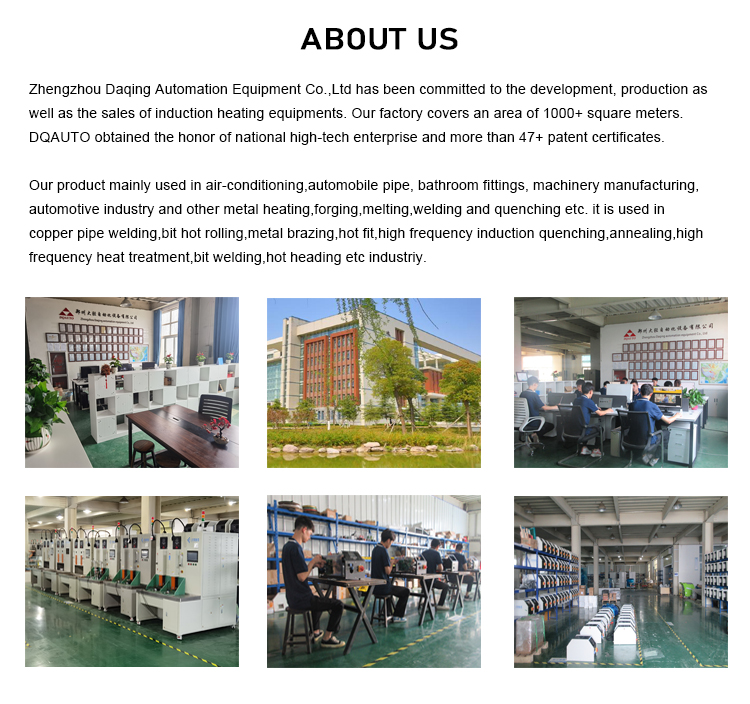

Company Profile

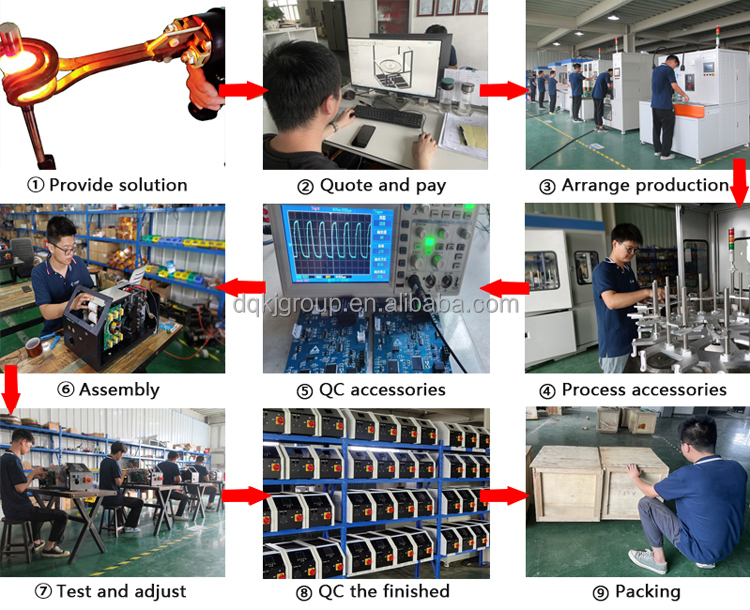

Production Process

Why choose us

FAQ

Q: Why use induction heating?

Answer: ★ Improve process efficiency ★ Local, constant, precise heating ★ Temperature control

★ energy saving ★ can be integrated into the production line ★ best quality and yield/performance

★ Pollution-free, fast and safe technology★ Improve working environment

Q: How to choose the right induction heater?A: Induction heaters come in many different models, with different wattages and frequencies.

1. The greater the power, the faster the heating speed. So if you want to heat up quickly then you'd better choose a high-power induction heater.

2. The higher the frequency, the lower the heating layer. Therefore, for some surface hardening we recommend higher frequency heaters and for some bulk heating such as forging and melting we recommend low frequency heaters.

3. If you are not sure which model is suitable for your job, please seek advice from our sales before placing an order.

If you are interested in our products, please write down your requirements in the space below and click"send"Drop us a line and we'll get back to you within 24 hours. Kind tips: If possible, please tell us what workpiece do you need to heat? Material and size? Heating requirements? Forging, hardening, brazing or other heating purposes? These help us recommend the most suitable machine model to you. Thanks. |

VIEW MORE

YOU MAY LIKE