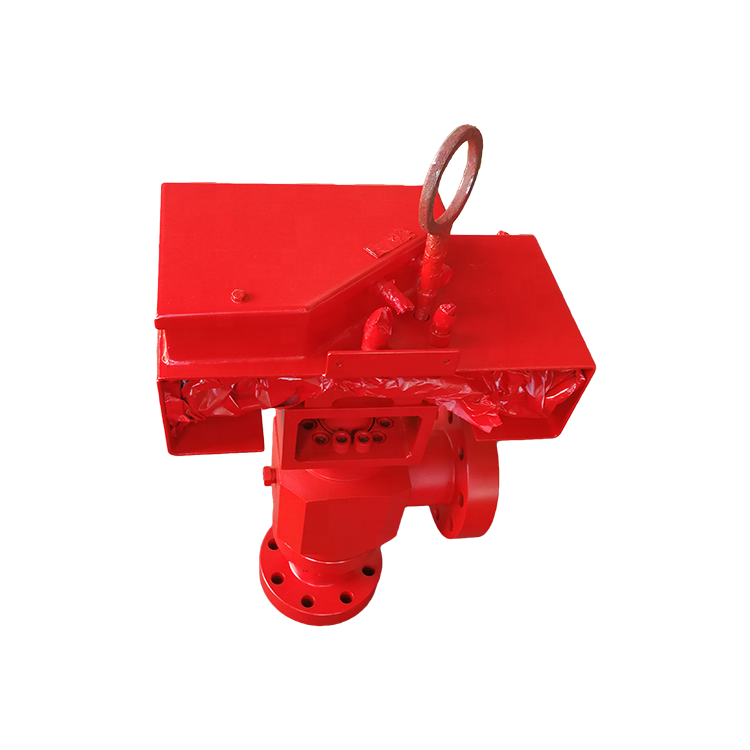

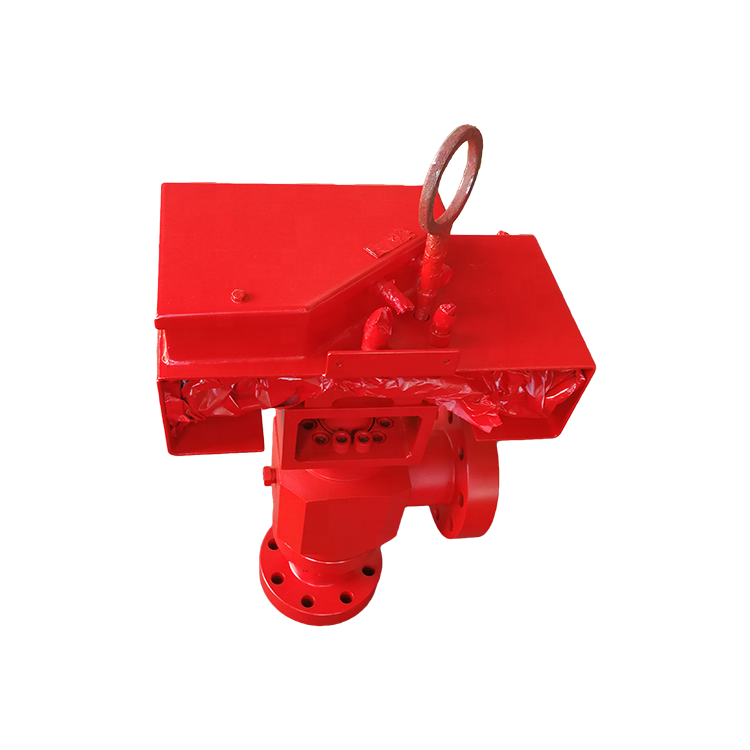

API6A 2-1/16" 10000PSI Cameron Choke/Positive Choke with Choke Bean/Adjustable H2 Choke

- $1100.00 /set

- 1 set

- Jiangsu Hongxun Oil Equipment Co., Ltd.

- Jiangsu, China

- Ms Yuan Ada

PRODUCT DETAIL

| application: | oilfield | feature: | throttle valve |

| Showroom location: | not any | place of origin; place of origin: | China |

| Marketing Type: | normal product | product name: | API6A throttle valve |

| Production capacity: | 200 sets/month | port: | Shanghai Port |

| Original location: | China | Core components: | Seat / Choke |

| Packaging Preview: | Material: | 4130 Forging | |

| Supply capacity: | 200 sets per month | temperature: | Polyurethane |

| pressure: | 2000PSI to 15000PSI | Manufacturing Standards: | API6A/NACE-0175 |

| usage: | Wellhead/manifold | Health status: | new |

| Choke beans: | YG8 alloy | brand: | Hongxun |

| Video external inspection: | if | payment terms: | L/C,T/T,Western Union |

| Warranty: | 1.5 years | Applicable industries: | Energy and Mining, Oilfield Upstream |

| After-sales service provided: | Video technical support, online support | size: | 1-13/16'' to 7-1/16'' |

| Connection end: | Flange/Joint | Packaging Details: | Export-friendly glulam crates |

| Core Components Warranty: | 1.5 years | Local service location: | not any |

| Mechanical test report: | if |

Product Description

Cameron DEMCO Mud Gate Valve 7500PSI

size | 3-1/16'' |

pressure | 1000PSI |

MC | EE-0.5 |

temperature | Polyurethane |

PSL | 3 |

PR | 1 |

cameron jocks family

The throttle valve is composed of needle type adjustable flow valve, positive throttle valve, cage type throttle valve and SWACO hydraulic orifice plate type throttle valve, and is mainly used for onshore and offshore oil drilling and exploitation. Design and Quality Control

In line with international standards. The valve body is made of high-quality low-alloy steel and processed with advanced technology

Complies with API 6A 20th Edition and NACE MR-0175.

In line with international standards. The valve body is made of high-quality low-alloy steel and processed with advanced technology

Complies with API 6A 20th Edition and NACE MR-0175.

feature

H2 chokes are mainly used for wellhead Christmas trees and choke manifolds.The valve core and choke beans are made of high wear-resistant carbide, which can withstand long-term erosion and corrosion.

SWACO Hydraulic Throttle Valves are

Mainly suitable for drilling, fracturing, mud circulation and onshore high pressure gas injection and production. During the closing period,

The pressure difference between the inlet and outlet pushes the two holes tightly against each other to seal and shut off

VIEW MORE

YOU MAY LIKE