Accurate and dimensionally consistent US standard polyurethane concrete floor stamping dies

- $5.00 / >=20 kilograms

- 20 kilograms

- Shanghai Pepsen Polyurethane Co., Ltd.

- Shanghai, China

- Mr Ban Xue

| proportion: | 1.2 g/cm3 | application: | Streets, parking lots, squares, gardens, streets, greenery |

| deal with: | Yes or no | payment terms: | L/C, T/T, Western Union, MoneyGram |

| Delivery Details: | 10 days after order confirmation | model: | 1117 |

| product: | put up | hardness: | Shore 75A |

| product material: | Polyurethane | Origin: | China Shanghai |

| Type 2: | Floppy or FLEX | Shaping mode: | die casting |

| tolerant: | +/-1 to 3.5 mm | Warranty: | Pure imported raw materials |

| brand: | yum | Type 1: | rigid stamp or pad |

| port: | Shanghai | color: | Red, yellow, blue, green, black, orange, transparent |

| Impressions of concrete: | good and deep | Packaging Details: | Wooden box--concrete stamping mold |

| Supply capacity: | Annual output of 600 tons of concrete stamping dies |

What is the difference between high quality and low quality concrete stamping dies?

High quality stamps have some characteristics that distinguish them from low quality stamps.

1. They are tightly combined without gaps.

2. Stamp thickness is the same.

3. Straight corners and correct alignment.

4. The handle is firmly fixed and will not protrude from the bottom.

5. The texture is clear, sharp and lifelike.

6. The pattern changes from tool to tool and creates a random look.

A quality stamping tool should be reusable many times and last for many years if cared for properly.

Types of Concrete Stamps and Their Applications

Rigid Punching - Rigid pads are used for most punching jobs and they have handles for lifting and placing. They left a wonderful and deep impression.

Upholstered or Upholstered Pads - These are about half as thick as rigid pads and are made of very flexible polyurethane. They have no handles and are not usually used to stand on. Their primary use is for stamping edges, corners, walls and columns.

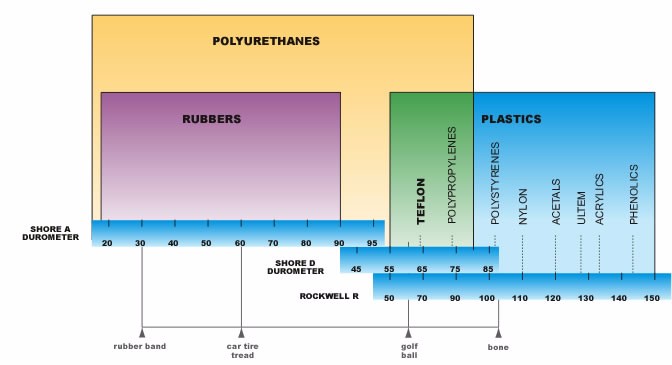

What is the hardness range of polyurethane/polyurethane?

What colors can we provide?

What polyurethane formulations can we provide?

Application-specific polyurethane formulations for:

• wear-resistant

• High rebound

• Low compression set

• High load capacity

• high temperature

• Excellent dynamic mechanical formulation

• oil resistance

• Solvent resistance

• Hydrolysis resistance

• Flame retardant, antistatic, anti-oxidation, anti-mildew, anti-aging, lubricating, etc...

Why choose us?

• Quick response within 12 hours

• Reliable imported raw materials

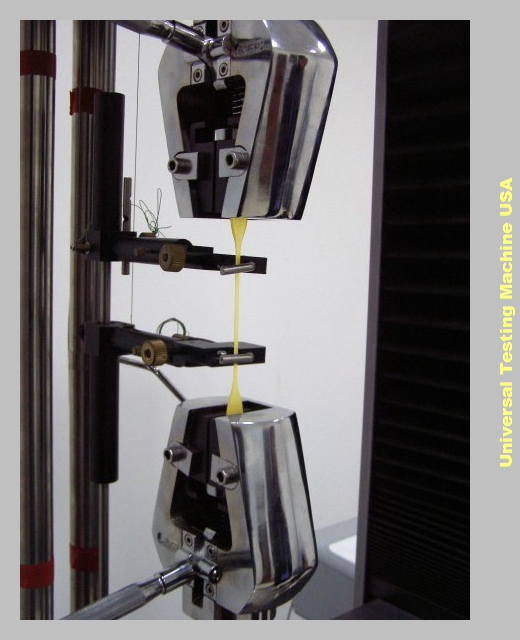

• Strict analysis and testing of raw materials before production

• Assistance from initial idea to prototype

• First prototype inspection after mold forming and before series production

• Rapid delivery of prototypes or production requirements

• Design assistance and part integration

• In-house mold design (insert, urethane, urethane molding)

• In-house formulation to provide the optimal polyurethane for your application

• Low cost tools

• Over 20 years of in-house experience

• Reliable after-sales service and support

Shanghai Pepson Polyurethane Co., Ltd. (ISO9001:2008 certified manufacturer, audited by Bureau Veritas, with a registered capital of RMB 5 million and a production area of over 3,400 square meters) was established in 1997 and is located in Shanghai, China. PEPSEN specializes in the research and manufacture of high performance standard and custom molded polyurethane elastomer products. In addition, some polyurethane products manufactured by PEPSEN comply with SGS and RoHS approved material specifications. believe us! PEPSEN engineering staff has over 20 years experience in custom cast molded polyurethane production.

our team

Q1: Are you a factory?

A1: Yes, we are a factory focusing on polyurethane for 20 years.

Q2: How many workers in your factory?

A3: We have 85 workers, 80% of them have been working for us for more than 5 years.

Q3: Is it possible to customize and small order?

A2: Yes, samples or drawings are enough. 1 piece or 1000 pieces are available.

Q4: How do you do QC control?

A4: We have 10 inspectors who inspect from raw materials, samples, operations, semi-finished products to final products.

Q5: How do you deal with customers' complaints?

A5: If it is our responsibility, we will replace the order or make a refund.