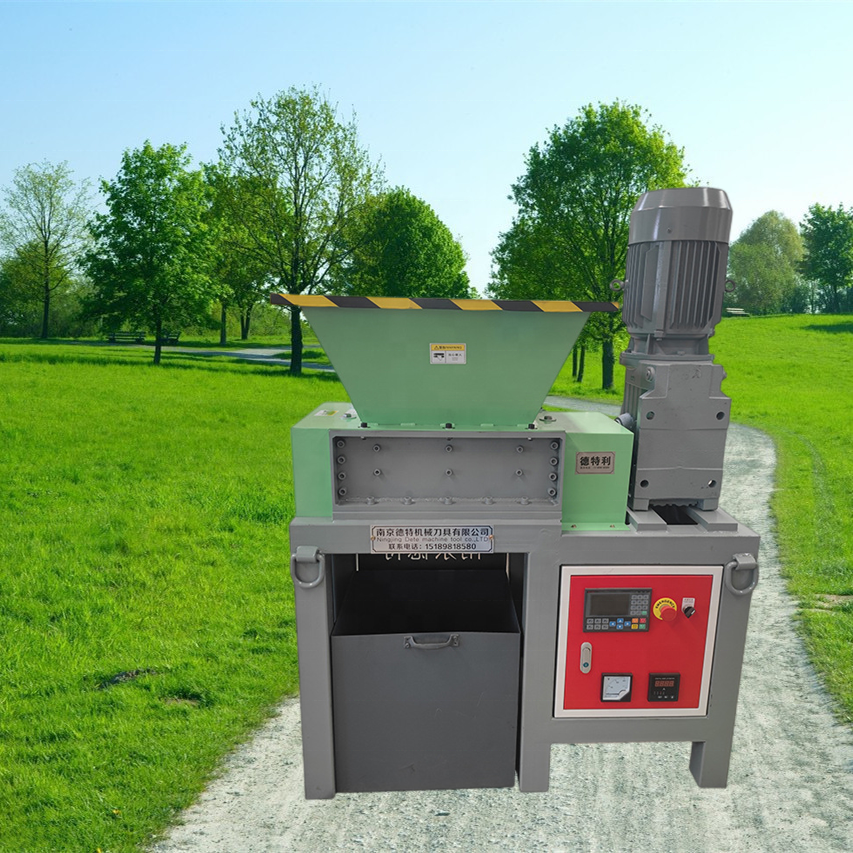

Automatic Plastic Shredder Industrial Heavy Duty Single Shaft Steel Shredder Wood Shredder

- $1600.00 / 1 - 4 sets

$1500.00 / 5 - 9 sets

$1300.00 / >=10 sets - 1 set

- Nanjing Dete Machine Tool Co., Ltd.

- Jiangsu, China

- Mr amalia

PRODUCT DETAIL

| Production capacity (kg/hour): | 100 - 2500 kg/h | Warranty: | motor 1 year |

| Maximum production capacity (kg/h): | 2500 | feature: | Efficient, safe and long life |

| size: | customer drawing | Key words: | shredder shredder |

| Card: | det | Type of machine: | plastic shredder |

| Showroom location: | Pakistan | Packaging Details: | 1. Multiple layers of plastic wrap and cardboard protect the plastic recycling machine from dust and moisture. 2. Plastic packing straps are used to fix the packaging film and the machine, and are also used to fix the machine inside the container. 3. When choosing LCL, air freight or international express, use wooden case as outer packing and spare parts. 4. An excellent logistics team ensures the safe delivery of the shredder to the location designated by the customer. |

| place of origin; place of origin: | Nanjing, Jiangsu Province, China | Video shipment inspection: | if |

| Package preview: | Supply capacity: | 3000 sets per year | |

| Drive mode: | gear | Dimensions (L*W*H): | custom made |

| Voltage: | custom made | Shaft design: | double |

| use: | waste plastic shredder | Core components: | motor |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Manufacturing Plants, Machinery Repair Shops, Food and Beverage Plants, Farms, Restaurants, Home Use, Retail, Food Stores, Printing Shops, Construction, Energy and Mining, Food and Beverage Stores, Other, Advertising company |

| Main selling points: | easy to operate | Plastic Type: | PVC,PET,ABS,PP/PE,PE,PP,PMMA,PA,PS |

| brand: | det | Marketing Type: | New Products 2022 |

| Package: | wooden box | Health status: | new |

| Mechanical test report: | if | Weight (ton): | 6.8 |

| Material: | Metal | port: | Shanghai, Ningbo |

| After warranty service: | Video technical support | After-sales service: | online support |

| Core component warranty: | 1 year |

Product Description

Shredder Product Advantages:

1. The knife holder and blade on the rotor are detachable, which is convenient for cleaning, maintenance and maintenance;

2. Each moving knife has 4 cutting edges, which can be rotated 90° for continued use after wear;

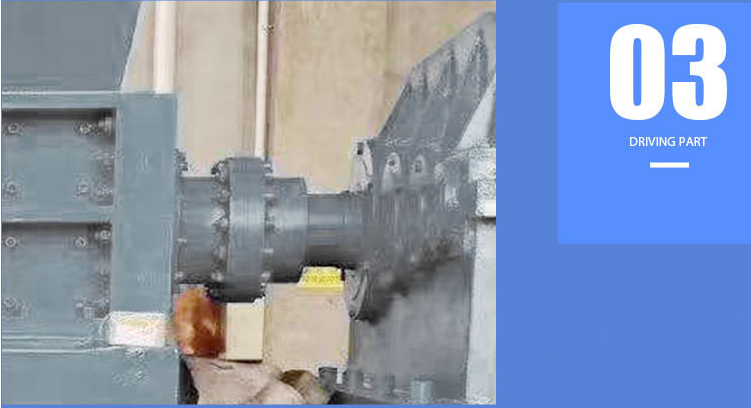

3. The main shaft is driven by a gear reducer, with stable operation, low noise and large torque;

4. The PLC program control system is adopted, which can automatically reverse and make the machine run smoothly;

5. The box body is tempered after welding to eliminate welding stress;

6. The installation position of the moving knife is precisely processed by the machining center to ensure that the gap between each moving knife and the fixed knife is the same;

7. The moving knife holder is embedded in the knife shaft with high-strength screws. It can prevent the phenomenon of knife drop caused by long-term vibration of welding type.

8. It is easy to transport after tearing, which can reduce transportation costs and improve transportation efficiency, which is convenient and fast

Secondary processing.

Secondary processing.

show details

Annealing heat treatment, tempering heat treatment

Wire cutting fine grinding preservation.

welding, high precision, good contact, low

Low noise and long service life.

Shredder transmission parts adopt

coupling links, reduce vibration, protect

Main shaft and reducer, no power loss.

shredder motor

Shredder adopts copper core motor

to reduce energy consumption and have long-term

service life.

Types of Shredded Items

VIEW MORE

Other Products

-

Dete small shredder metal waste single and double shaft shredder chassis plastic rubber shredder$99.00 - $300.00 / set

Dete small shredder metal waste single and double shaft shredder chassis plastic rubber shredder$99.00 - $300.00 / set -

Grinder Crusher Crusher Granulator Granulator Blade Crusher Blade Strong Plastic Blade Low Noise Plastic Online Support 0.2 ABS$280.00 - $300.00 / set

Grinder Crusher Crusher Granulator Granulator Blade Crusher Blade Strong Plastic Blade Low Noise Plastic Online Support 0.2 ABS$280.00 - $300.00 / set -

industrial iron ore crusher plant price$600.00 - $800.00 / set

industrial iron ore crusher plant price$600.00 - $800.00 / set