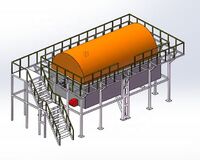

Best price silicone doll machine doll vinyl toy making equipment plastisol molding rotomolding machine

- $25000.00 / 1 - 9 sets

$20000.00 / >=10 sets - 1 set

- Jieyang Airport Zone Zhong Wang Machine Factory

- Guangdong, China

- Ms bing qui

PRODUCT DETAIL

| application: | Blow Molded Products | Supply capacity: | 1000 sets per month |

| brand: | ZW | After-sales service provided: | Video technical support |

| Core components: | pressure vessel | Showroom location: | not any |

| Video external inspection: | if | Mold opening and closing power: | Steam (0.8MP) 1320KG pressure |

| Packaging Details: | Box | Maximum speed: | 60 times/m |

| Dimensions (L*W*H): | 40*1200mm | Applicable industries: | manufacturing plant |

| Voltage: | 380V 50H | Electric heating power: | 4KW |

| Marketing Type: | New Products 2020 | Core Components Warranty: | 1 year |

| place of origin; place of origin: | Guangdong, China | product name: | Plastic water bottle blowing machine |

| Main selling point: | high productivity | Mechanical test report: | if |

| Product Category: | PE doll hollow body | Local service location: | not any |

| Warranty: | 1 year | weight: | 900 |

| port: | Shenzhen | Health status: | new |

| payment terms: | L/C,Western Union,T/T,MoneyGram,PayPal,Trade Assurance,etc. |

Product Description

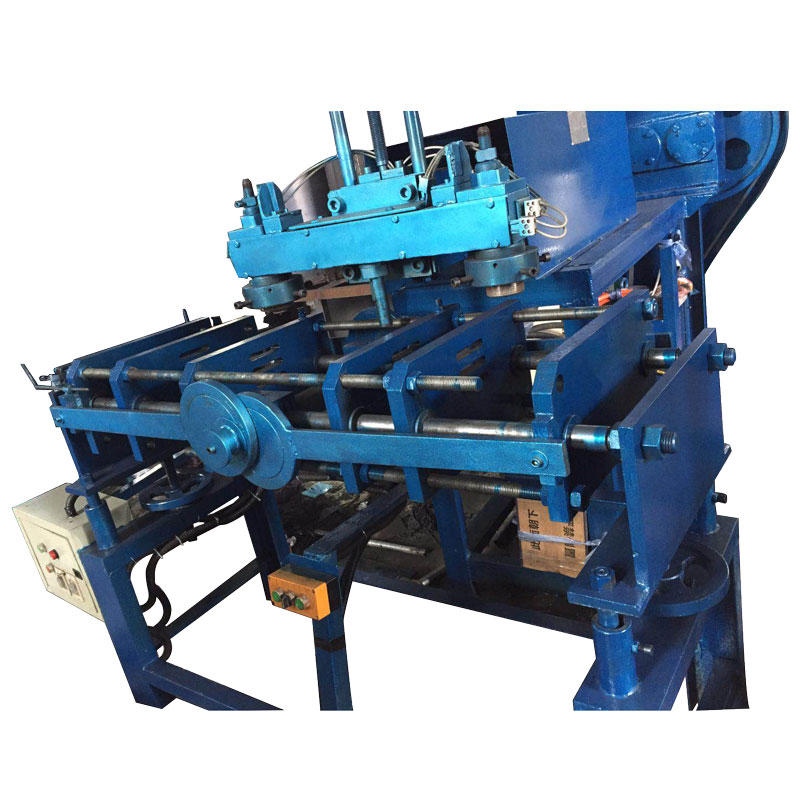

Model (MM) | A 40*1200 | Model (MM) | B 50*1600 | Model (MM) | C 60*1900 |

Mold opening and closing force | Steam (0.8MP) Pressure 1320KG | Mold opening and closing force | Steam (0.8MP) Pressure 1600KG | Mold opening and closing force | Steam (1.0MP) Pressure 2800KG |

speed | 60 times/m | speed | 50 times/m | speed | 30 times/m |

Operating Voltage | 380V 50H | Operating Voltage | 380V 50H | Operating Voltage | 380V 50H |

Motor Power | 5.5KW | Motor Power | 7.5KW | Motor Power | 11KW |

Electric heating power | 4KW | Electric heating power | 5.5KW | Electric heating power | 8.5KW |

Machine Features:

Blow molding machine is a kind of various plastic hollow products made of PE material, such as dolls, water bottles,

Other hollow plastic bottles have strong adaptability and easy operation. The working principle is: conveying PE material or other materials through a screw

The powder material is sent to the external heating cylinder, the PE melt enters the liquid extrusion outlet, and passes through the mold cup.

Packed into tubular plastic and pushed into working mould inside. Fill the tubular plastic with air so that it expands and closes

The mold wall is finally cooled and demolded to produce various hollow products. Our products are characterized by energy

Energy saving and high efficiency, the machine adopts frequency conversion instant sol, block heat preservation

With heating zone, the outlet has about two buttons and about two mold bases, which can be produced continuously.

Other hollow plastic bottles have strong adaptability and easy operation. The working principle is: conveying PE material or other materials through a screw

The powder material is sent to the external heating cylinder, the PE melt enters the liquid extrusion outlet, and passes through the mold cup.

Packed into tubular plastic and pushed into working mould inside. Fill the tubular plastic with air so that it expands and closes

The mold wall is finally cooled and demolded to produce various hollow products. Our products are characterized by energy

Energy saving and high efficiency, the machine adopts frequency conversion instant sol, block heat preservation

With heating zone, the outlet has about two buttons and about two mold bases, which can be produced continuously.

front

back

detailed image

waterproof material

High quality zipper

Built-in dual airbags

VIEW MORE

YOU MAY LIKE

Other Products

-

Cheap Steel Manufactures Football PVC Plastic Toys Prais Plastic Ocean Sea Blowers Manufactures Rubber Balls$10000.00 - $15000.00 / set

Cheap Steel Manufactures Football PVC Plastic Toys Prais Plastic Ocean Sea Blowers Manufactures Rubber Balls$10000.00 - $15000.00 / set -

High quality full printing plastic ocean ocean kids pvc ball making rubber toy molding machine pvc ball making machine$28000.00 - $30000.00 / set

High quality full printing plastic ocean ocean kids pvc ball making rubber toy molding machine pvc ball making machine$28000.00 - $30000.00 / set