C31HD drill auger teeth for drilling tools cutter bit

- $15.00 /piece

- 1 piece

- Hunan Unicorn Machinery Co.,ltd.

- Hunan, China

- Ms unicorn drill

| Weight: | 0.5-2.4kg; | Brand Name: | UNICORN DRILL; |

| Use: | Coal Mining; | Applicable layers: | Soil, earth, rock, clay, mud, etc.; |

| Machine: | For rotary drill rig auger bucket; | Supply Ability: | 10000 Pieces per Week; |

| Payment Terms: | L/C,T/T,Western Union,e-checking,visa,master card; | Type: | Bucket teeth; |

| Application: | Pile Foundation; | Hardness: | 50-54 HRC; |

| Machine Type: | Drilling Equipment; | Processing Type: | Forging,Forging; |

| Material: | Carbide,Carbon steel, Tungsten carbide, 42CrMo; | Certification: | ISO9001:2008,ISO9001:2008; |

| Place of Origin: | Hunan, China; | Packaging Detail: | Packed with Plastic box or wooden cases.; |

| Port: | Changsha Port/Shenzhen Port /Shanghai Port / Tianjin Port; | Factory: | Yes; |

| Other Type: | B47K20H, B47K19H, B47K17H, 3050, 3060, 3065; |

Unicorn Drill Drilling Auger & Continuous Flight Auger (CFA) adopt the high-carbon steel (Q345B, 16Mn, Q195-Q345, etc.) and special drilling bits (B47K20H, B47K19H, B47K17H, 3050, 3060, 3065,C30, C31HD, B85, B43H,18TL, 18HD, 25VIP, 18VIP, 25T, 25HD, 22T,833-18,855 25,18PN/LK,25PN/LK ) angle to keep the drilling strength and efficiency.

Purchase the standard drilling buckets.

1)Single Cut Conical Rock Auger & Double Cut Conical Rock Auger

Main Applications:Single Cut Auger are suitable for drilling in medium to strong rock (15-60 Mpa). double cut auger is recommended in uncased bores or for bigger diameters.

Features: Sturdy and wearable rock pilot for accurate positioning.

Hard facing strips on flights for wear protection.

Kelly box: 130*130, 150*150, 200*200 or as required (optionl).

CONICAL AUGER TECHNICAL DATA

Drilling Dia mm | Flight Dia mm | Pitch mm | Flight Length mm | Teeth Qty pcs | Single cut Weight kg | Double Cut Weight kg |

| 600 | 550 | 600 | 1200 | 20+4 | 438 | 537 |

| 700 | 650 | 600 | 1200 | 20+4 | 467 | 596 |

| 800 | 750 | 600 | 1200 | 22+4 | 512 | 708 |

| 900 | 850 | 600 | 1200 | 22+4 | 586 | 775 |

| 1000 | 950 | 600 | 1200 | 24+4 | 633 | 871 |

| 1100 | 1050 | 600 | 1200 | 26+4 | 674 | 958 |

| 1200 | 1150 | 600 | 1200 | 28+4 | 718 | 1047 |

| 1300 | 1250 | 600 | 1200 | 28+4 | 767 | 1145 |

| 1400 | 1350 | 600 | 1200 | 30+4 | 821 | 1253 |

| 1500 | 1450 | 600 | 1200 | 32+4 | 875 | 1367 |

| 1800 | 1750 | 600 | 1200 | 36+4 | 1081 | 1766 |

2)Single Cut Flat or Butterfly Auger & Double Cut Flat or Butterfly Auger

*Flat or butterfly rock auger

Mian Applications: Single cut flat or butterfly rock auger are suitable for drilling in very dense sand and gravel, weak rock (<5 Mpa). Double cut auger is recommended in uncased bores or for bigger diameters and secant pile walls.

Features: Sturdy and wearale rock pilots for accurate poitioning.

Hard facing strips on flights for wear protection.

Kelly box: 130*130, 150*150, 200*200 or as required (optional).

FLAT OR BUTTERFLY ROCK AUGER TECHNICAL DATA

Drililng Dia mm | Shell Dia mm | Pitch mm | Flight Length mm | Teeth Qty pcs | Single Cut Weight kg | Double Cut Weight kg |

| 600 | 550 | 600 | 1200 | 4+2 | 481 | 559 |

| 700 | 650 | 600 | 1200 | 4+4 | 519 | 630 |

| 800 | 750 | 600 | 1200 | 6+4 | 560 | 705 |

| 900 | 850 | 600 | 1200 | 6+4 | 614 | 802 |

| 1000 | 950 | 600 | 1200 | 8+4 | 675 | 910 |

| 1100 | 1050 | 600 | 1200 | 10+4 | 741 | 1029 |

| 1200 | 1150 | 600 | 1200 | 10+4 | 809 | 1153 |

| 1300 | 1250 | 600 | 1200 | 12+4 | 887 | 1293 |

| 1400 | 1350 | 600 | 1200 | 12+4 | 973 | 1447 |

| 1500 | 1450 | 600 | 1200 | 18+4 | 1059 | 1606 |

| 1800 | 1750 | 600 | 1200 | 22+4 | 1364 | 2155 |

*Flat or butterfly soil auger

Main Applications: Single cut flat soil auger are suitable for drilling in soft to stiff silt and clay, loose to medium dense sand and gravel. Double cut flat soil auger is recommended for uncased bores or for bigger dimeters.

Features: Fish-tial pilots for accurate positioning.

Hard-facing strips on flights for wear protection.

Kelly box: 130*130, 150*150, 200*200 or as required (optional).

FLAT OR BUTTERFLY SOIL AUGER TECHNICAL DATA

Drilling Dia mm | flight Dia mm | Pitch mm | Flight Lenght mm | Teeth Qty pcs | Single Cut Weight kg | Double Cut Weight kg |

| 600 | 550 | 600 | 1200 | 4 | 478 | 569 |

| 700 | 650 | 600 | 1200 | 4 | 516 | 630 |

| 800 | 750 | 600 | 1200 | 4 | 554 | 700 |

| 900 | 850 | 600 | 1200 | 5 | 610 | 796 |

| 1000 | 950 | 600 | 1200 | 6 | 668 | 904 |

| 1100 | 1050 | 600 | 1200 | 6 | 732 | 1016 |

| 1200 | 1150 | 600 | 1200 | 6 | 800 | 1139 |

| 1300 | 1250 | 600 | 1200 | 7 | 879 | 1279 |

| 1400 | 1350 | 600 | 1200 | 8 | 959 | 1429 |

| 1500 | 1450 | 600 | 1200 | 9 | 1050 | 1590 |

| 1800 | 1750 | 600 | 1200 | 11 | 1351 | 2132 |

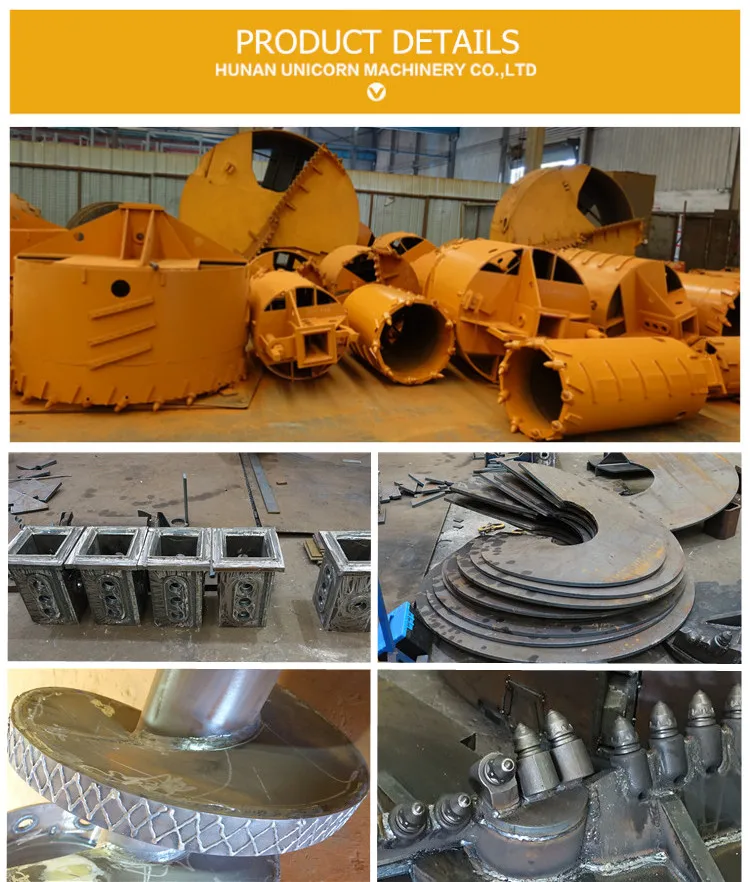

Customized your own drilling buckets

(1). Kelly Box: design various type and size 130*130, 150*150,200*200 or as required .

(2).Spiral Height: design as demand, according to the piling diameter and soil condition prolong or shorten, increase of efficiency by drilling more.

(3).Spiral Pitch:adjust the spiral pitch according to different working condition.

(4).Cutter: single cutter or double cutter and with pilots or without pilots design as demand;

(5).Key Component Reinforce : strengthen the key component to extend life cycle.

(6).Model of Teeth:

Rock Bits:B47K20H, B47K19H, B47K17H, 3050, 3060, 3065,C30, C31HD, B85, B43H, etc.

Clay Teeth:18TL, 18HD, 25VIP, 18VIP, 25T, 25HD, 22T,833-18,855, etc.

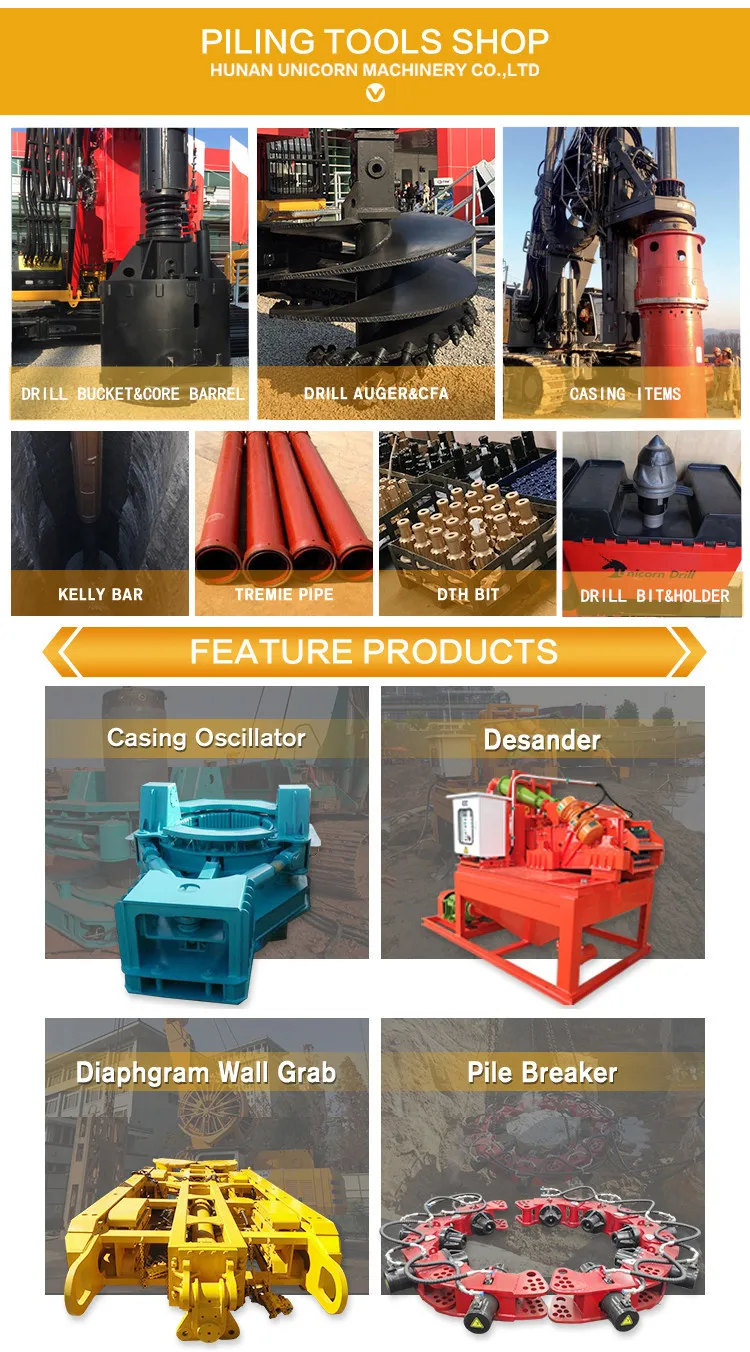

Related Products

At A Glance

Unicorn Drill is a company dedicated to the designing and manufacturing of drilling tools and tailor-made Kelly Bars for pilling rigs in China since 2011. When Unicorn Drill decide to create the world class drilling tools, we have already clearly in mind the outline of business plan: to become the benchmark in the production of tools and to let the whole industry been impressed by China manufacturing.

At Unicorn Drill, our mission is to meet the needs and wants of our customers by providing the high-performance drilling tools and exceptional service through a team with unique technic and character.

Our Products

In the foundation engineering field of pilling, and accessories for rotary drilling rig , as well as soil investigation, we currently supply: drilling buckets, drilling augers,continue flight auger, drilling bits, drilling teeth, tailor-made kelly bar, casing tube, casing drive, casing shoe, casing teeth, casing oscillator, tremie pipe, pile breaker.

Quality Control

A good production project starts from supply for raw material; the skills and the human resources are the “treasure” of our company. The Unicorn Drill begins to develop a precise structure, a strong aptitude for technological innovation, the enhancement of human capabilities, upgrading and international. The team today is a very dynamic group, consolidated in the wide range of products and constantly looking for new solutions to the increasingly complex challenges faced by civil engineering worldwide.

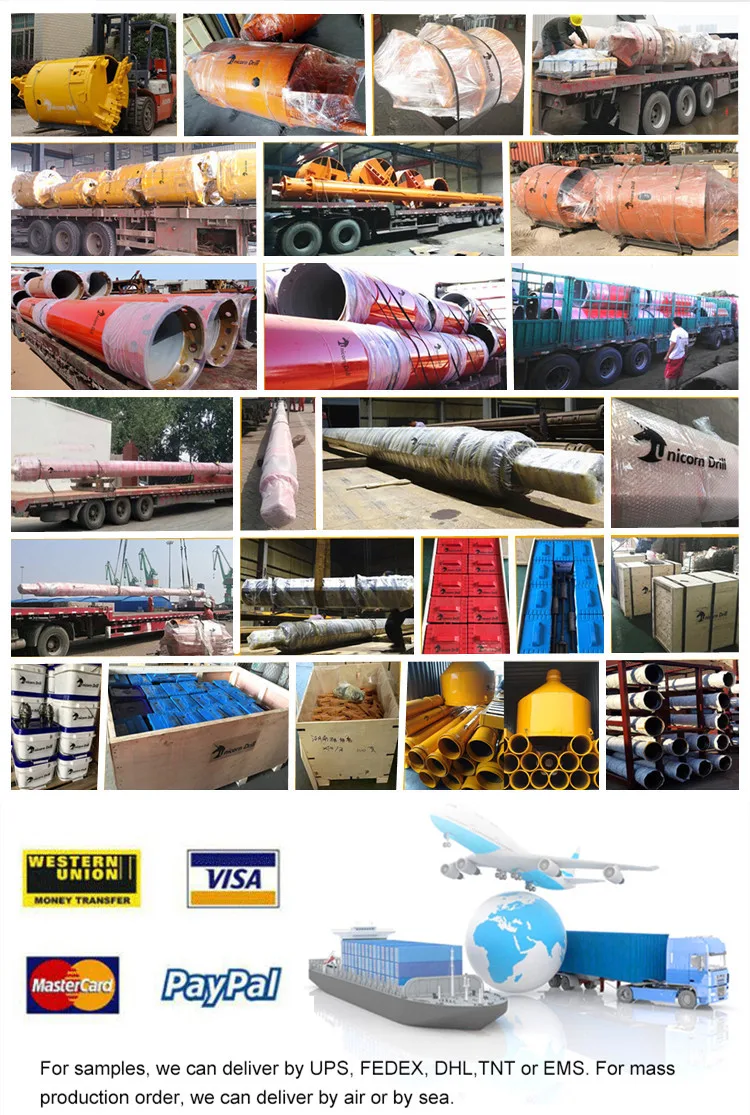

1.100% Inspection before shipment.

2. Wrapped with plastic film.

3. Fixed with iron support, wheel or pallet when necessary.

4. Packed with plastic cases and wooden cases for drilling bits, clay teeth.