Cheese making machine cheese processing line Cheese project in hand

- $12500.00 /set

- 1 set

- Shanghai Beyond Machinery Co., Ltd.

- Shanghai, China

- Ms Beyond Machinery

PRODUCT DETAIL

| Showroom location: | Pakistan, Russia, Kenya, Sri Lanka, Bangladesh | feature: | High efficiency and low cost |

| Certification: | CE and ISO | Warranty: | 1 year |

| Core Components Warranty: | 1 year | Packaging Preview: | |

| Finished goods: | Soft Cheese/Mozzarella/Cheddar | Video external inspection: | if |

| Health status: | new | Raw materials: | Fresh and milk powder |

| Applicable industries: | Manufacturing Plants, Food and Beverage Plants, Food and Beverage Stores, Dairy Plants | Mechanical test report: | if |

| Function: | heat fermentation | payment terms: | L/C,Western Union,T/T |

| Supply capacity: | 300 sets per year | capacity: | 500L-1500L |

| Name: | cheese production line | Packaging Details: | Wood packaging; container pickup; film packaging |

| Dimensions (L*W*H): | 2250*1145*1100mm | usage: | diary product |

| weight: | 500kg | brand: | Exceed |

| place of origin; place of origin: | China Shanghai | port: | Shanghai |

| strength: | 3-5kw | Marketing Type: | New Products 2022 |

| Voltage: | 220V/380V/415V | Core components: | PLC, motor, pressure vessel, pump |

| application: | milk/cheese | Main selling point: | high productivity |

| Material: | AISI304/316 |

product description

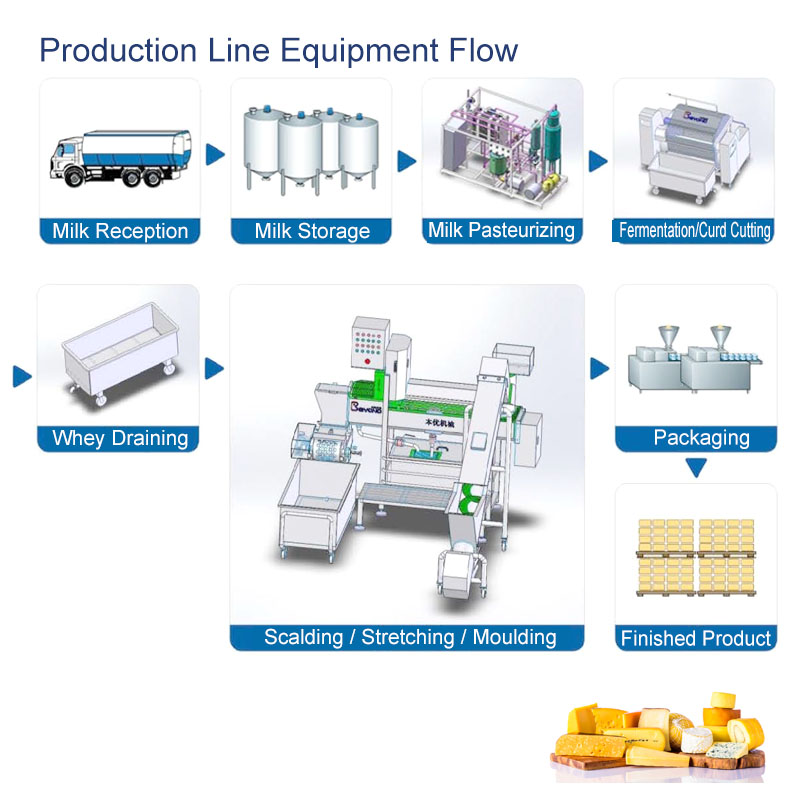

cheese processing line cheese making machine cheese turnkey project

Cheese barrels are used on dairy farms, specifically for cheese production. It is an essential equipment for processing all kinds of cheese. The milk enters the tank through the filter from the feeding port, and is heated and fermented in the tank, further stirred and chopped. The whey in the fermented milk is then drained through the outlet, leaving the cheese in the vat.

Function list

advantage:

1. Opportunity to realize products with customized formulations.

2. There is an opportunity to produce more than one product with the same processing line.

3. High-quality final products maintain high nutritional value.

4. Extensive customization of final products.

5. Maximize output and minimize production waste.

6. Using the most advanced technology, the highest energy saving.

7. Perfect production line monitoring system, by monitoring each process stage.

8. Recording, visualization and printing of all daily production data.

1. Opportunity to realize products with customized formulations.

2. There is an opportunity to produce more than one product with the same processing line.

3. High-quality final products maintain high nutritional value.

4. Extensive customization of final products.

5. Maximize output and minimize production waste.

6. Using the most advanced technology, the highest energy saving.

7. Perfect production line monitoring system, by monitoring each process stage.

8. Recording, visualization and printing of all daily production data.

Front view

Cheese bucket placed on platform

small cheese bucket

Product Specifications

Do not | thing | data | ||

1 | strength | 1.5KW-3KW | ||

2 | capacity | 300-2000L | ||

3 | Material | SUS304/SUS316 | ||

4 | shape | Oval | ||

5 | agitator | 2 mixers; one is a mixer; the other is to cut the cheese into curds | ||

6 | control type | Temperature automatic control panel; automatic drain whey outlet | ||

7 | External dimensions | 2145*1459*1000mm(500L) 2600*1600*1200mm(1000L) |

Product configuration

cheese barrel for fermentation

temperature sensor

Electric control cabinet

Interested in dry cheese production?We are happy to help the cheese factory start producing white cheese and succeed.

Here are some reasons to choose a white cheese line:Turnkey delivery. We offer a complete white cheese line including white cheese VAT, cooling/washing tanks, integrated whey drain and white cheese creamer. We also supply high quality packaging machines through our network. This makes it easy to get all your equipment from one place. high yield. Our fully automatic and high-efficiency cheese washing lines are among the best in the market. Our equipment makes efficient use of existing milk and achieves good profitability. reliable quality. Our white cheese plants are used by the largest white cheese production plants in Europe. Cheese jar - full-featured cheese jar is controlled by PLC, and the speed of all knives is adjusted by frequency converter. The floating cylinder is mechanically durable due to its design and robust shaft material. Customers compare our cheese casks to competitors' casks and find that the cheese casks have the highest yield. The main advantages of using a cheese pot are: A single cutting method optimizes the yield and shape of the curd. After cutting, the longitudinal cutter is not inside the product, but lifts up automatically. The short distance from the tool to the tank wall ensures that less uncut curd remains and the best mixing results. Our cheese jars feature automatic rennet dispensing: when the rennet is poured into the rennet dispensing jar, the jar is automatically pressurized and the rennet is sprayed evenly into the milk inside the cheese jar. The heating unit is also integrated: there is a steam regulating valve, a heat exchanger and a pump for the heating water circuit of the barrel. The PLC controls the steam flow and optimizes the heating water temperature for the different heating stages. System cleaning CIP.

successful project

Mongolia Project

Saudi Arabia project

Thailand project

VIEW MORE