China Manufacturer Industrial Kiln / Lime Calcination Rotary Kiln

- $5000.00 /set

- 1 set

- Henan Zhengzhou Mining Machinery Co., Ltd.

- Henan, China

- Ms Katia Zhao

| Mechanical test report: | if | strength: | model-based |

| price: | Negotiable reasonable | Certification: | International Organization for Standardization |

| Voltage: | 220v/380v/400v/440v | Applicable industries: | Manufacturing plant, energy and mining, cement plant, energy mining |

| Test & install: | under the guidance of engineers | Core component warranty: | 1 year |

| Limestone feed particle size/mm: | 10-50mm | Showroom location: | not any |

| After-sales service: | On-site installation, commissioning and training, overseas engineers | place of origin; place of origin: | Henan, China |

| Core components: | PLC, engine, gear | design: | Provide design proposal |

| Video shipment inspection: | if | weight: | Depending on the model, 200000 kg |

| brand: | Zhengkang brand | Health status: | new |

| Warranty: | 1 year | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| port: | Shanghai, Tianjin, Qingdao | Temperature/°C: | 1100±50 |

| Marketing Type: | 2019 Hot Products | Light overheating rate/%: | ≤5 |

| Supply capacity: | 50 sets per year | Dimensions (L*W*H): | According to the solution |

| Packaging Details: | Standard export packaging. | Turnkey basis: | Yes |

| Main selling points: | energy saving |

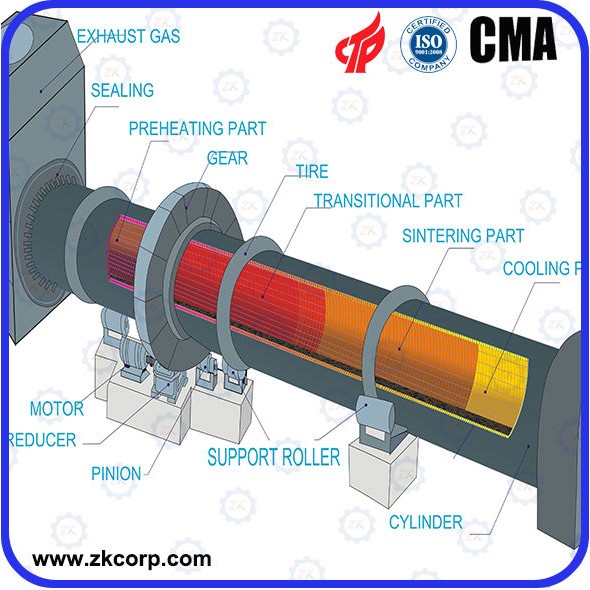

Lime rotary kiln is the main equipment of lime production line. Widely used in metallurgy, chemical industry, building refractories, environmental protection and other industries.

The rotary lime kiln is composed of cylinder body, supporting device, thrust roller supporting device, driving device, movable kiln head, kiln tail sealing device, coal ash pipe device, etc. The kiln body and level. The entire kiln body is supported by a roller support device, and is equipped with a thrust roller device to control the up and down movement of the kiln body. (Call us for more information)

1. High degree of automation:The resolution of limestone entering the kiln can reach 20-25%. In addition, the fineness of limestone is about 10~15mm, which can be used directly.

2. Effective reuse of waste heat:The air leakage coefficient is less than 10%, reducing radiation heat loss.

3. Low energy consumption:Limestone is kept at about 80°C by vertical coolers, which is very convenient for transportation and storage. The secondary air can also be preheated to over 700°C to recover waste heat and reduce energy consumption.

|

Model |

Production (tons/day) |

Main drive (r/min) |

Motor (kW) |

Adjustment range (r/min) |

Gearbox ratio |

Weight (tons) |

|

Φ2.2×50 |

96 |

0.125-1.25 |

30 |

132-1320 |

157 |

130.71 |

|

Φ2.5×50 |

130 |

0.516-1.549 |

55 |

440-1320 |

99.96 |

167.5 |

|

Φ3×48 |

850 |

0.3309-3.309 |

Post-90s |

100-1000 |

32.11 |

237 |

|

Φ3.2×48 |

1000 |

0.375-3.75 |

160 |

100-1000 |

27.469 |

252 |

|

Φ3.2×50 |

1200 |

0.398-3.975 |

190 |

150-1500 |

40.85 |

263 |

|

Φ3.3×52 |

1200 |

0.391-3.91 |

190 |

100-1000 |

27.707 |

280.8 |

|

Φ4×60 |

2500 |

0.396-3.96 |

315 |

100-1000 |

34.601 |

487.5 |

|

Φ4.2×60 |

2800 |

0.4165-4.165 |

420 |

100-1000 |

35.526 |

576.1 |

|

Φ4.3×62 |

3000 |

0.398-3.98 |

420 |

100-1000 |

35.714 |

598.5 |

|

Φ4.3×64 |

3200 |

0.449~4.49 |

450 |

100~1000 |

24.365 |

585 |

|

Φ4.5×66 |

4000 |

0.41~4.1 |

630 |

100~1000 |

34.069 |

710.4 |

|

Φ4.8×70 |

5000~5500 |

0.4~4.0 |

630 |

100-1000 |

30.876 |

845.3 |

|

Φ4.8×72 |

5000 |

0.403~4.03 |

560 |

100~1000 |

30.365 |

847 |

|

Φ4.8×74 |

5000 |

0.35~4 |

630 |

130~1500 |

42.226 |

841 |