Cold glue frame making PVC profile wrapping machine

- $5900.00 / 1 - 4 units

$5650.00 / >=5 units - 1 unit

- Foshan City WEHO Machinery Co., Ltd.

- Guangdong, China

- Ms Liu Sherry

| Heating power: | 6kw; | After-sales Service Provided: | Video technical support; |

| Min.wrapping length: | 600mm; | Feeding motor power: | 1.5kw; |

| Core Components: | Motor; | Applicable Industries: | Building Material Shops,Manufacturing Plant,factory; |

| Weight: | 2500kg; | Voltage: | 380V; |

| After Warranty Service: | Video technical support,Online support; | PVC wrapping speed: | Adjustable; |

| Dimension(L*W*H): | 4500*600*1800; | Machinery Test Report: | Provided; |

| Application: | PVC profile wrapping machine; | Marketing Type: | Ordinary Product; |

| Showroom Location: | None; | Key Selling Points: | High-accuracy; |

| Video outgoing-inspection: | Provided; | Power: | 7.5kw; |

| Payment Terms: | L/C,T/T,Western Union,MoneyGram; | Max.film wrapping width: | 300mm; |

| Max.process thickness: | 90mm; | Package Preview: | ; |

| Local Service Location: | None; | Condition: | New; |

| Max.diameter of PVC Roll: | 400mm; | Warranty: | 1 Year; |

| Packaging Detail: | Flim or wooden case 4000X600X1800mm; | Warranty of core components: | 1 Year; |

| Place of Origin: | Guangdong, China; | Certification: | CE; |

| Customized Max width of wrapping PVC: | 600/850/1200mm; | Brand Name: | WEHO; |

| Wrapping material: | PVC, aluminium or wpc; |

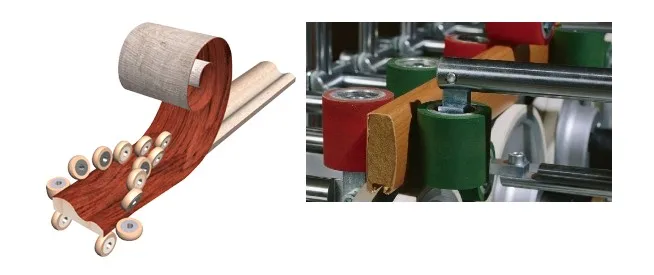

Cold glue cheap China PVC profile wrapping machine

For Window wraps plastic, pvc or paper profiles wrapping,with reel-mounted materials. Available in three versions with maximum working widths 310 mm, 400 mm and 550 mm or special size is customized.

PVC roll maximum diameter 400mm.

Proprietary engineering and vast wrapping experience have resulted in a great cost-to-value ratio.

Frequency-controlled drives for pvc and workpieces conveyor. .

All-In-One Adhesive Application Unit includes; melter, application pump and slot-coater.

Quick set-up with adjustment optimization system for transport wheels.

Telescopic switch cabinet. Un-winder for reel mounted materials.

PVC Wrapping zone equipped with easy to use quick change systems.

Central width adjustment for the wrapping zone.

Silicone rubber rollers.

|

Product |

PVC profile wrapping machine |

|

Max.film wrapping width |

300mm |

|

Max.process thickness |

90mm |

|

Min.process length |

600mm |

|

Feeding speed |

0-35m/min |

|

Feeding motor power |

1.5kw |

|

Heating power |

6kw |

|

Overall dimensions |

4000x600X1800mm |

|

Weight |

2500kg |

|

Max.diameter of roll cover material |

400mm |

|

Custom-made Max width of cover film |

600/850/1200mm |

Best solution for PVC profile wrapping machine.

Quality and excellent customer service,guarantee complete systems,for profile wrapping machines of out standing technical performance.

In the initial processing phase,systems guarantee high quality preparation and treatment of the profile surfaces and aconsider able control of the production process,that is made safe and reliable.

Suitable tor building materials, furnitures,table tops,doors,windows,or related manufacturers use. Complex Shapes can achieve the perfect products pvc profile wrapping processing.

PVC profile wrapping machine features and uses

Specially used for decorative lines and aluminum, plastic materials,

Surface is covered with PVC film and milamine paper.

Using high standard glue, it can cover all angles, arcs, bumps, grooves, curls, etc.

Suitable for building materials, furniture, table tops, doors and windows, decorative strips or related professional manufacturers.

It can perfect the surface of complex shape products.

WEHO Machinery is an original equipment manufacturer, all machines can be custom built to the customer requirements. We can design and manufacture most of wood processing machines.

WEHO Machinery is an original equipment manufacturer, all machines can be custom built to the customer requirements. We can design and manufacture most of wood processing machines.

How to buy

How to do if I can not operate

How to get spare part after warranty