Concrete garage floor epoxy

- $5.00 /kilogram

- 1 kilogram

- Shenzhen Mei Taibang Chemical Co., Ltd.

- Guangdong, China

- Mr Jianjun Qiu

| Epoxy floor paint: | self-leveling | Packaging Details: | For Epoxy Floor Sheets for Garage Floor Coatings, packages are available in 3 gallon kits, 15kg kits and 60kg kits, we can pack according to your design and requirements. |

| port: | Shenzhen | How to apply: | Brushes and Coatings |

| Colorless and low odor: | color chip | Packaging Preview: | |

| place of origin; place of origin: | Guangdong, China | Oil resistance: | anti-UV |

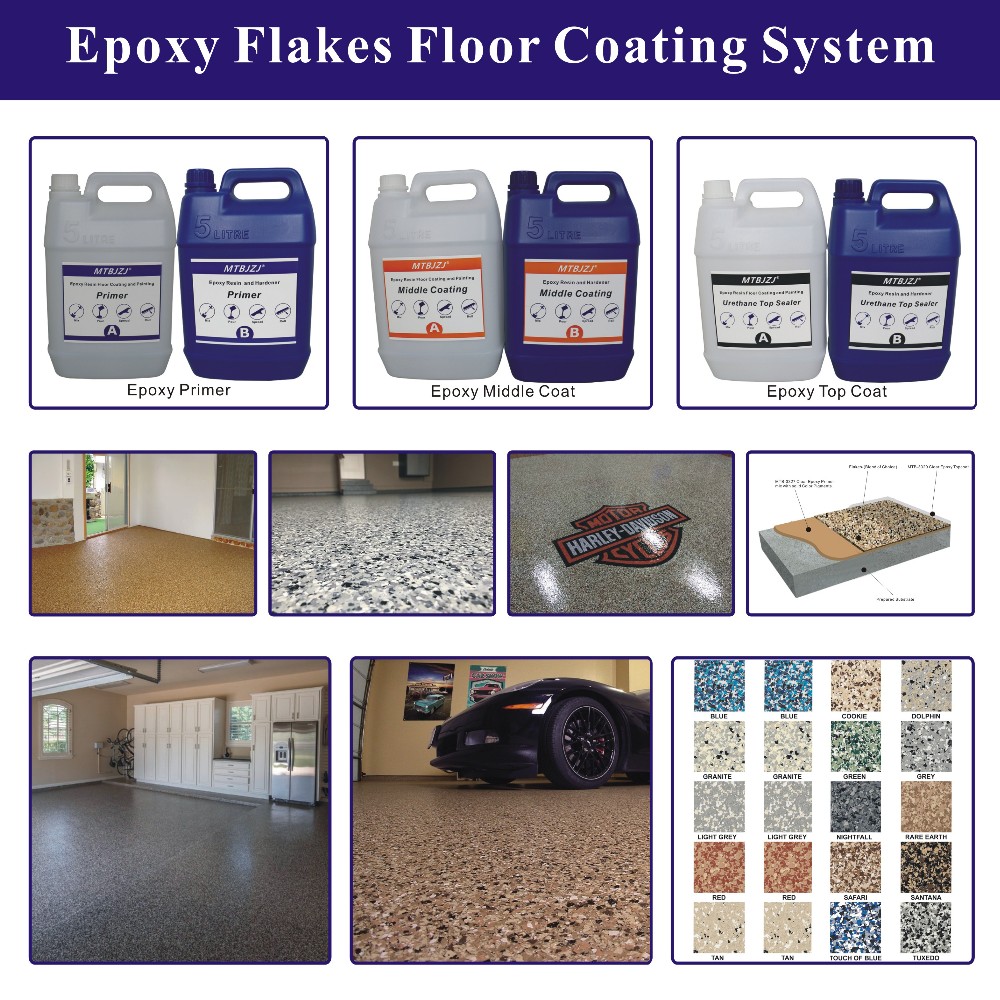

| brand: | MTBJZJ | model: | MTB-3327,MTB-3328,MTB-3329 |

| Scratch Resistant: | No volatile organic compounds | payment terms: | L/C,Western Union,T/T |

| Supply capacity: | 10,000 gallons of epoxy sheet flooring per week | Non-toxic: | chemical resistance |

| state: | liquid paint | Other names: | Epoxy floor paint |

| main ingreadient: | epoxy resin | CAS number: | 61788-97-4 |

| waterproof: | 15 years warranty | 1/4" and 11/16" Thin Chips: | 12m shelf life |

| IF: | (C11H12O3)n | Solvent free: | 3 Coatings of primer, midcoat and topcoat |

| usage: | Appliance Coatings, Architectural Coatings, Floor Coatings and Paints | 60 colors of chip chips for your choice: | 1-3mm, 3-5mm chip chip |

| High glass: | non-slip | EINECS number: | other |

Industrial and commercial epoxy floor system

MTB-3328 Epoxy middle coat--Greatly improve the wear resistance and density of the coated floor, improve the service life, and make the bottom layer and the surface layer a perfect transition. Generally transparent, 100% solid content, two components of epoxy resin and curing agent, the mixing ratio of 2:1, you can add color chips or color chips according to your own requirements, so that your floor color is as you want would like to need.

MTB-3329 epoxy self-leveling surface coating or top coat

• Low VOC green products

• no yellowing

• extremely fast drying

• Longer cure times can be delayed

• Deep penetration into porous concrete

• Abrasion resistant floor system

• Resistant to most chemicals

• High profile finish

• Heat resistant tires

Why choose epoxy floor system?

The benefits of epoxy coatings are numerous and varied, making epoxy floors the first choice for many businesses. Here are a few reasons why our epoxy floors will bring the greatest benefit to your facility!

Affordable

Epoxy coatings provide inexpensive and durable protection for concrete floors that lasts for years and reduces maintenance costs over time. Businesses that use epoxy paint typically spend less money on floors over time.

Chemical/Splash Resistant

Epoxy floors can be formulated to provide chemical resistance to specific types of chemicals for businesses that require this type of chemical resistance for worker safety.

safe

Epoxy floors are available in non-slip, impact and fire resistant options for a variety of industries. This increases productivity while reducing accidents and near misses on the job site.

color coating

For this purpose, different colored epoxy sheets are used to designate specific work areas within a single building, indicating which areas are used for storage, vehicle parking, walking, etc.

durable

Epoxy coatings are highly resistant to damage from long-term use, setting your floors and work environment for long-term success.

attractive

Available in different colors and pattern spots, epoxy coatings are an asset in showrooms and stores, where product presentation is critical to the success of the business.

• High Quality • Non-porous • Stain Resistant • Easy Maintenance

• Strong and flexible • UV resistant • non-toxic • non-slip

| 0.25kgs~0.3kgs/㎡ | |||

Surfaces and locations that can be improved with MTB Epoxy Floor Flake Chips

• Pool deck and terrace

• Retail Flooring

• Concrete garage floor

• Commercial flooring applications

• Workshop area

• Garage floor paint with flakes

• 3D design

• Epoxy coating enhancer

• Multi-coloured floors

• Showroom floor

• Concrete floors

• Garage floor epoxy coating

Decorative vinyl chips, flakes

Epoxy Epoxy Flake Flooring, also known as Decorative Vinyl Color Flake, Flake or Flake Paint, is a coating polymer coating used in the correct combination with garage floors. This incredibly unique product is randomly shaped but standardized in size and pre-blended into a wide and rich palette of colors and palettes.

Industrial and commercial epoxy floor system

We have the following packaging for your reference

---1 gallon/barrel, 3 gallons/kit

---5kgs/barrel, 15kgs/kit

---20kgs/barrel, 60kgs/kit

For flake chips, we have the following packages for you to choose

--500g/bag

---20kg/bag

Other Products

-

2:1 slow speed without bubbles deep pouring resin 5-10cm$5.00 / kilogram

2:1 slow speed without bubbles deep pouring resin 5-10cm$5.00 / kilogram