Electric plywood hydraulic wooden door 120 ton 50 ton furniture cold press

- $1980.00 / 1 - 4 sets

$1700.00 / >=5 sets - 1 set

- Jinan Grandio Cnc Equipment Co., Ltd.

- Shandong, China

- Ms Kaise Ellen

PRODUCT DETAIL

| Packaging Details: | Guandiao International Grandio brand GD3248-50 veneer 50 tons cold press information 1. Packaging form: cling film packaging. 2. Package size: 1250x2900x3000mm. Electric plywood hydraulic wooden door 120 ton 50 ton furniture cold press | Maximum pressure (T): | 60 |

| Main selling point: | easy to operate | Voltage: | 380V/220V |

| type: | cold press | Downstroke: | 1/1.3/1.5m |

| Video external inspection: | if | Package dimensions: | 1250x2900x2300mm |

| Mechanical test report: | if | product name: | cold press |

| weight: | 2000kg | Maximum platen thickness: | 0.98/1.28/1.48m |

| Health status: | new | Maximum platen opening: | 1000mm (1300mm optional) |

| Motor Power: | 4Kw/5.5Kw | brand: | Grandio NC |

| Supply capacity: | 1000 sets per month | working desk size: | 1250*2500mm |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram | Applicable industries: | Building Materials Stores, Mechanical Repair Shops, Manufacturing Plants, Households, Printing Shops, Energy & Mining, Advertising Agencies |

| Weight (kg): | 2000kg | Core Components Warranty: | 3 years |

| Table size (mm): | 1250×2500 | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

| Marketing Type: | New Products 2021 | pressure: | 50T,50T |

| Power (kW): | 12 | Cylinder: | 125mm*2pcs 90mm*2pcs |

| Warranty: | 1 year | place of origin; place of origin: | Shandong China |

| Packaging Preview: | Showroom location: | Philippines, Peru, Mexico, Morocco, Chile, Colombia | |

| port: | Qingdao | Dimensions (L*W*H): | 1300*3000*2800mm |

Product Description

Electric plywood hydraulic wooden door 120 ton 50 ton furniture cold press

-High quality 50T hydraulic cold press.

1. This cold press is mainly used for pressing and preforming of plywood, and has the characteristics of good pressing quality and high efficiency.

2. Widely used in furniture manufacturing industry and other sheet metal production industries.

2. Widely used in furniture manufacturing industry and other sheet metal production industries.

Specification

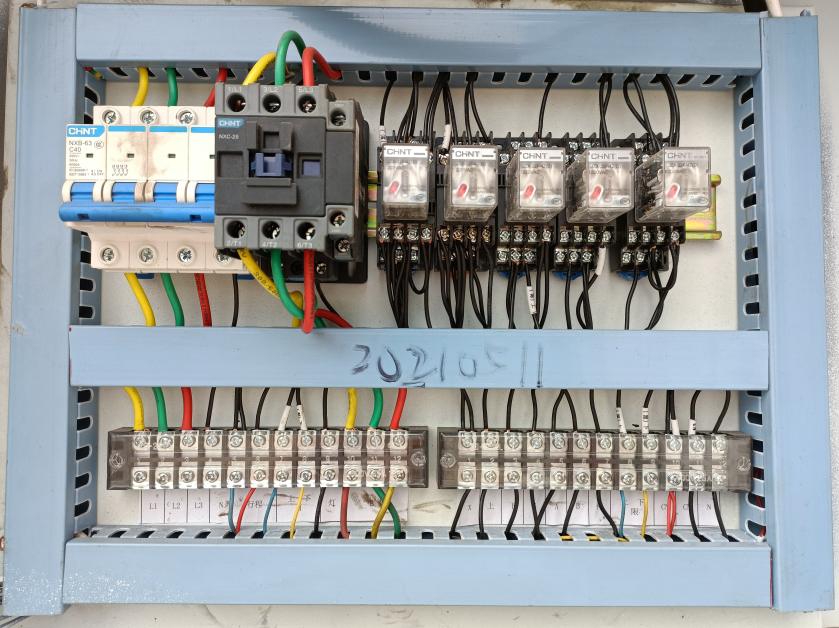

1. Most of the electrical components of this machine are selected from Schneider or Siemens, and the main components can be selected with CE certified products.

2. The steel plate of our machine is customized according to the pressure requirements to achieve the pressure, quality assurance we promise.

3. The upper and lower pliers are finished by gantry milling to ensure absolute flatness.

4. It adopts hydraulic system to work, with fast lifting speed, uniform pressure and high efficiency.

5. With overpressure automatic control circuit and pressure oil cutoff protection, automatic lift, automatic oil cutoff.

6. Fast and efficient pressing, emergency safety braking, limit device.

7. Automatic compression and pressure relief function.

8. The height of the workbench is convenient for workers to operate..

Name | GD3248X50T cold press | |||||

Platen size | 1250x2500mm | |||||

maximum total thrust | 50t(1.6kg/cm2) | |||||

hydraulic system pressure | 210 kg/cm² | |||||

Maximum platen opening | 1000mm (1300mm optional) | |||||

Cylinder | 125mmx2pcs 90mmx2pcs | |||||

Hydraulic motor power | 4kW | |||||

Dimensions | 1250x2900x3000mm | |||||

Contact me for more information | ||||||

The fuselage is welded and formed by 14mm thick steel plate, the table is processed by gantry milling, and the fuselage is

After anti-corrosion treatment, spray anti-corrosion paint to effectively prevent rust, beautiful and practical. .

The one-piece 314 oil cylinder ensures no oil leakage for a long time, and the pressure maintaining effect is good. On-site welding, the lower worktable adopts on-site forming welding structure, so that the pressure distribution of the entire worktable is even, the flatness of the pressure surface is guaranteed for a long time, and the quality of processed products is improved.

Button-type control panel, equipped with emergency stop switch and timing display, easy operation, emergency stop when power off, safe operation. Pressure maintaining control instrument, scale display, 0-50 tons pressure can be adjusted at will to ensure the safety of pressed products. The upper and lower travel limit switches can automatically stop lifting.

Ensure the safety of the whole machine line..

application

Woodworking Hydraulic Cold Press Flash Door Press

Hydraulic cold presses are widely used in furniture factories, audio factories, wood factories, decoration

Companies, advertising companies press furniture panels, wooden doors, plywood, plywood, solid wood doors, steel doors, stainless steel bathroom doors, kitchen aluminum cabinet doors, heating bricks, foam, etc. For levelling and shaping panels and furniture of all kinds of wood, the planks can be bonded more firmly.

Companies, advertising companies press furniture panels, wooden doors, plywood, plywood, solid wood doors, steel doors, stainless steel bathroom doors, kitchen aluminum cabinet doors, heating bricks, foam, etc. For levelling and shaping panels and furniture of all kinds of wood, the planks can be bonded more firmly.

contact us

VIEW MORE