Fully automatic dry cold press dog food machine production extrusion granulator dog cat pet food full line

- $1449.00 / 1 - 9 sets

$1249.00 / 10 - 99 sets

$1049.00 / >=100 sets - 1 set

- Henan Gondor Equipment Material Co.,Ltd.

- Henan, China

- Ms Betty Wen

PRODUCT DETAIL

| Material: | stainless steel 304 | Spiral diameter (mm): | 40-60 |

| Packaging Details: | wooden box | Video shipment inspection: | if |

| feature: | high efficiency | Warranty: | 1 year |

| Weight (kg): | 350-1450 | Voltage: | 220V |

| Dimensions (L*W*H): | 1360*1600*850 | application: | Pet Feed Facilities, Cats, Dogs, Birds, Fish |

| Core component warranty: | 1 year | brand: | Guangdong Province |

| Marketing Type: | New product | Model: | 40-200 |

| strength: | 5.5kw | Cutting power (kW): | 0.4-2.2 |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Feed power (kw): | 0.4-2.2 |

| Applicable industries: | Manufacturing plants, food and beverage plants | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

| Origin: | Henan, China | port: | Qingdao, Shanghai, Shenzhen, Ningbo, Tianjin, etc. |

| weight: | 350 kg | Host power (kw): | 5.5-110 |

| Health status: | new | Showroom location: | not any |

| Supply capacity: | 100 sets per month | Mechanical test report: | if |

Product Description

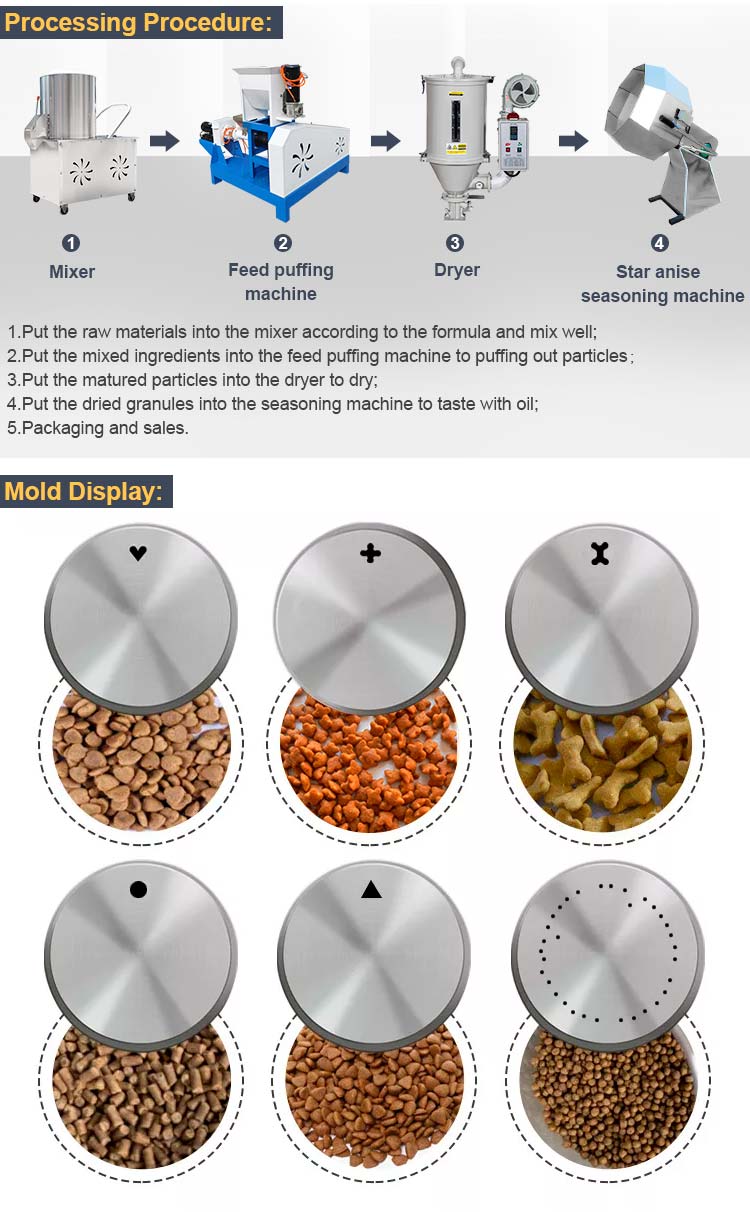

introduce:

The pet food extruder uses corn, soybean (bean cake), animal waste, etc. as raw materials. It can be extruded directly into the machine to produce different pellets. It has novel shape, unique taste, rich nutrition and excellent structure. It is suitable for different pet feeds such as dogs, cats, fish, birds, rabbits, shrimps, cats, mink, and foxes. It is suitable for professional farmers, small and medium-sized feed mills and laboratories. In the case of the same feed formula, the cost of homemade extruded feed is 60%-80% lower than the market price; the extruded feed particles produced by this machine are neat and smooth, and the floating water surface does not sink for more than 12 hours, does not pollute the water source, and can be sterilized, reducing fish sick

application:

1. This machine can be equipped with a variety of molds for the production of aquatic feed, pet feed, livestock feed, etc.

2. This machine can also expand raw materials such as corn and soybeans.

2. This machine can also expand raw materials such as corn and soybeans.

feature:

1. This machine has novel design, compact structure and high production efficiency.

2. Reliable, durable, low failure rate, easy operation and maintenance.

3.The machine is easy to operate, stable in transmission and low in noise.

4.The main parts are made of special alloy materials after heat treatment, which has a long service life.

5.It adopts dry puffing process, self-heating, no steam system, and can better meet the actual needs of users.

6.Screw design with strong self-cleaning function: the spiral groove of the screw is self-cleaning, so there is no need to stop cleaning when changing formulas and product varieties.

7. The machine is equipped with a feeding system and a cutter system, the feeding speed is adjustable, and the operation is more convenient.

Product parameters

parameter:

Model | productivity (t/h) | monitor rate (kilowatt) | Feed power (kilowatt) | Spiral diameter (mm) | cutting force (kilowatt) | Package Size (mm) | weight (Kilogram) |

GD-40 | 0.04-0.05 | 5.5 kW (220V) | 0.4 | Φ40 | 0.4 | 1360*1600*850 | 350 |

GD-50 | 0.08-0.09 | 11kw (380V) | 0.4 | Φ50 | 0.4 | 1360*1600*850 | 350 |

GD-60 | 0.12-0.15 | 15 | 0.4 | Φ60 | 0.4 | 1360*1670*850 | 450 |

GD-702 | 0.18-0.20 | 18.5 | 0.4 | Φ70 | 0.4 | 1360*1670*850 | 490 |

GD-703 | 0.20-0.25 | 18.5 | 0.4 | Φ70 | 0.4 | 1360*1670*850 | 490 |

GD-80 | 0.30-0.35 | twenty two | 0.55 | Φ80 | 0.55 | 1360*1950*840 | 600 |

GD-100 | 0.4-0.5 | 37 | 1.1 | Φ90 | 1.5 | 1800*2600*1150 | 800 |

GD-135 | 0.75-0.80 | 75 | 1.1 | Φ130 | 2.2 | 2200*2800*1200 | 950 |

GD-120 | 0.60-0.70 | 55 | 1.1 | Φ120 | 2.2 | 2200*2800*1200 | 950 |

GD-160 | 1.00-1.20 | Post-90s | 1.5 | Φ160 | 2.2 | 2300*3000*1200 | 1200 |

GD-200 | 1.80-2.00 | 110 | 2.2 | Φ160 | 2.2 | 2400*3200*1400 | 1450 |

product information

VIEW MORE

YOU MAY LIKE