GC9025 CNC small woodworking woodworking lathe

- $3100.00 /set

- 1 set

- Jinan Goodcut Cnc Machinery Co., Ltd.

- Shandong, China

- Ms Smile Ji

| maximum. Turning length (mm): | 1000 mm | Voltage: | 220 volts, 380 volts |

| Dimensions (L*W*H): | 1000mm length, 250mm diameter | software: | AutoCAD software |

| Optional parts: | Dust collection | maximum. Swing diameter (mm): | 250 mm |

| Blade: | single pole | Showroom location: | not any |

| Marketing Type: | New Products 2020 | Core components: | engine |

| transmission: | Imported bearing ball screw | Video shipment inspection: | if |

| Core component warranty: | 1 year | Health status: | new |

| Package preview: | application: | Round beads, wooden handles, small bowls, etc. | |

| Supply capacity: | 100 sets per month | Warranty: | 1 year |

| Length, diameter: | 900mm, 250mm size customization | Weight (kg): | 600 |

| brand: | good clip | Tailstock: | burden |

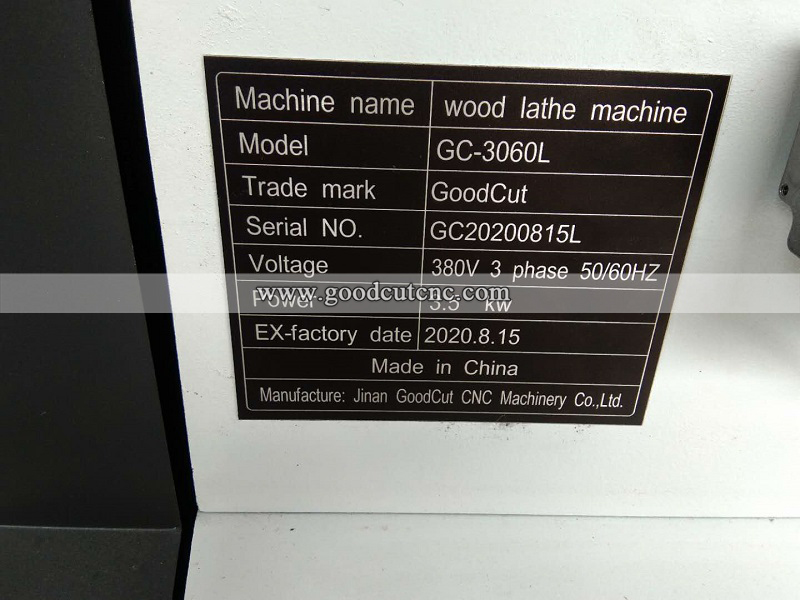

| port: | Qingdao | Machine name: | GC9025 CNC small woodworking woodworking lathe |

| cylinder: | yes, automatically fix wood | engine: | stepper motor |

| Origin: | Shandong China | maximum. Work piece length (mm): | 1000 mm |

| Packaging Details: | GC9025 CNC Small Woodworking Woodworking Lathe for Woodworking: Plywood | Main selling points: | high accuracy |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Mechanical test report: | if |

| Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Machinery Repair Shops, Manufacturing Plants, Home Furnishings, Retail, Construction Engineering, Energy and Mining, Advertising Agencies, Others |

GC9025 CNC small woodworking woodworking lathe

Technical Parameters:

| Model | GC9025 |

|---|---|

| Maximum processing length | 900mm |

| turning diameter | 250mm |

| air pressure | 0.6-0.8Mpa |

| power supply | AC 380V three-phase 50HZ/60HZ (customizable 220V) |

| feed rate | 2000mm/min |

| Minimum setting unit | 0.01cm |

| transmission type | XZ axis ball screw, Y axis gear |

| Tourist guide | Taiwan Silver Rail |

| Spindle speed | 0-3000 rpm |

| Motor Power | 4 kW |

| Tool material | Cemented carbide |

| Control System | CNC system |

| engine | stepper motor |

| driver | Yako driver |

| inverter | best inverter |

| Drawing software | AutoCAD software |

| interface | cable |

Operation method of small woodworking lathe

1. Input the required drawings in the software

2. Set Bead diameter, select shape, size.

3. No programming required, easy to use.

4. You can also design your own style, draw the outline, and also support BMP, JPG and other formats

1). The maximum working length is 900mm, and the maximum turning diameter is 250mm.

2). There are 2 knives on both sides of the machine, and the 2 knives work together, which greatly improves the efficiency.

Cutter life:

Using superhard alloy CNC tools, mahogany turning and milling without wear.

For example, if you process 3000 small-leaf red sandalwood with a diameter of 2cm, there is no need to change the tool.

advantage:

1. Computer numerical control

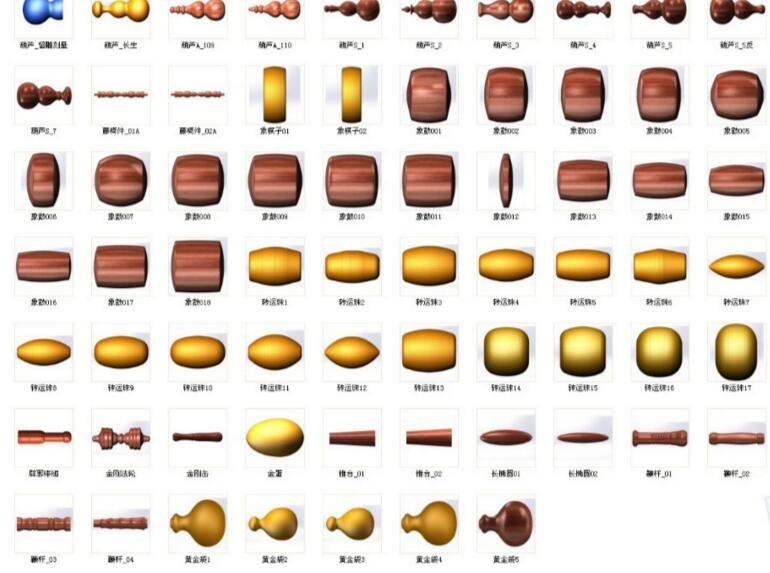

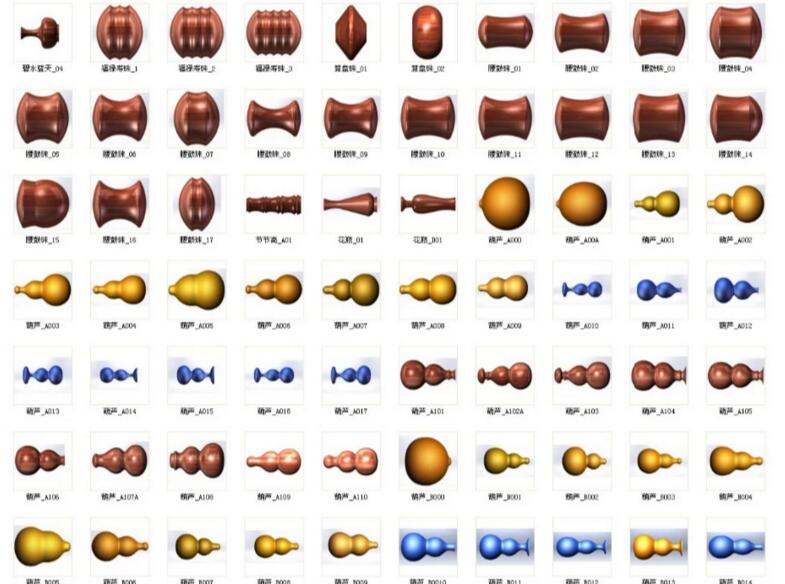

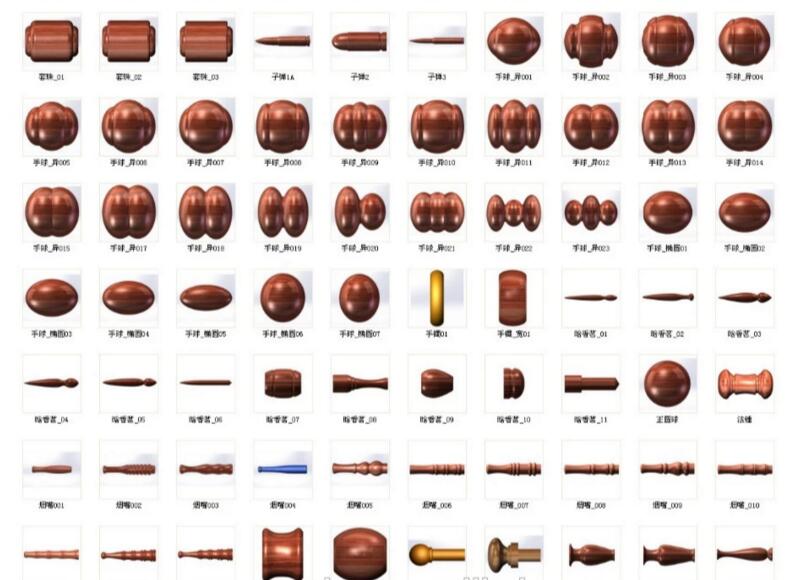

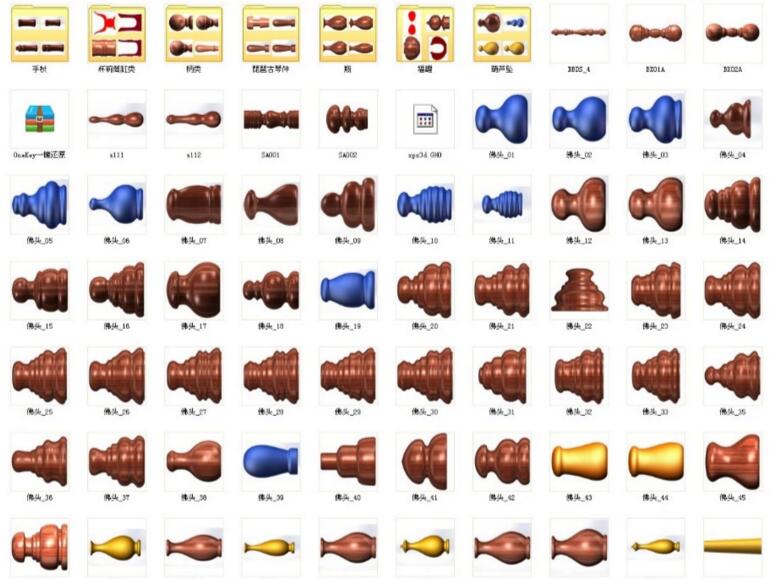

2. 600 kinds of beads dedicated gallery

3. Professional wooden bead machine control system, easy to operate

4. High-quality woodworking lathe knives, suitable for any kind of wood, long service life

5. Imported square guide rail and high-precision ball screw drive

6. High precision and stable working performance

Application of wood mini lathe

It can process various wood materials, such as beech, oak, pile wood, birch, teak, sapele, ash, merbau, sandalwood, rosewood and other wood materials.

Beads, cylinders, various Buddha head pagodas, gourd pendants, gourd pieces, wood rhinoceros horns, cups, bowls, whips, cigarette holders, eggs, ashtrays, scroll heads, wooden handles, etc.

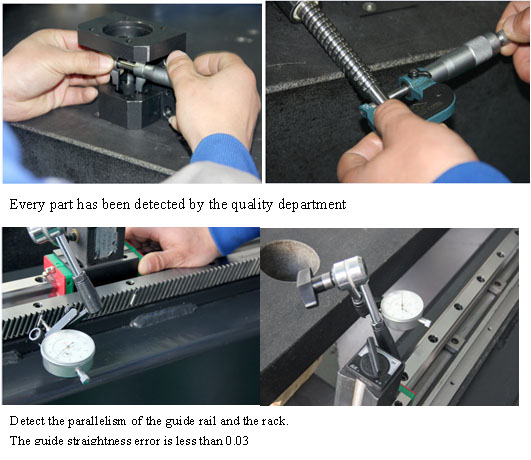

accurate:

Imported square track and ball screw drive

Long life and high precision

Processing accuracy: 0.01mm

Cutter life:

- Using superhard alloy CNC tools (special for stainless steel), mahogany turning and milling without wear.

- Process 3000 small-leaf red sandalwood with a diameter of 2cm without changing the tool.

- Long service life is standard

- piece. If it is damaged, replace it directly, no need to know sharpening skills.

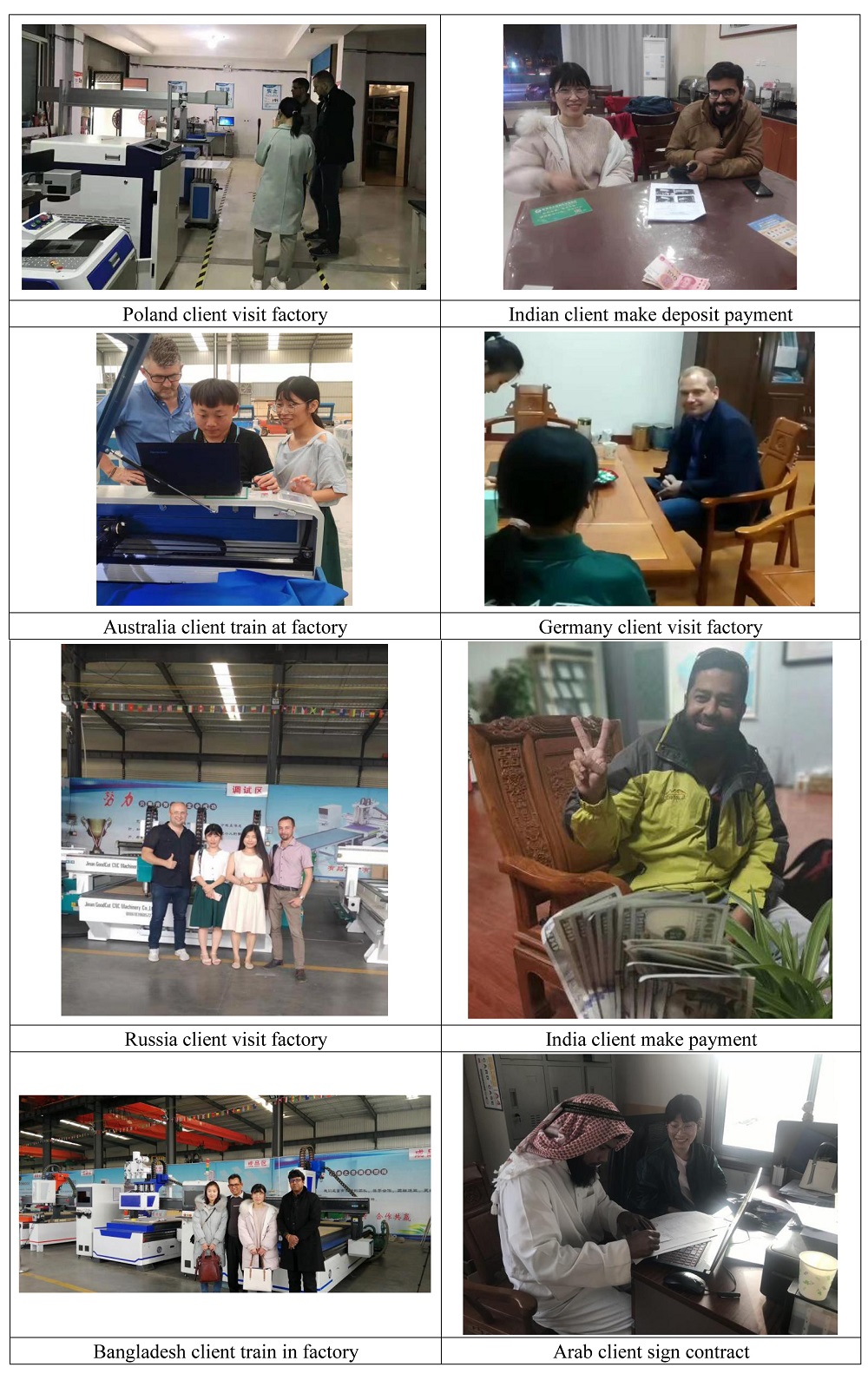

Jinan Guqie CNC Machinery Co., Ltd.

good clipThere are purchasing department, design department, production department, quality inspection department, packaging and transportation department, sales department and after-sales service department.

We can provide the highest quality machines and competitive prices.

Jinan Guqie CNC Machinery Co., Ltd.

"GoodCut" brand meaning: good quality, good price, good service

high quality

1. 15 engineers with more than 10 years of rich work experience, manufacturing high-precision machines;

2. Test the machine for 72 hours in three days, and ship it after confirming that the machine has no quality problems;

3. 4 QC personnel conduct strict evaluation on incoming inspection, process inspection and final inspection.

good price

1. GoodCut produces about 50 machines per month with large sales volume. We have long-term cooperation with component suppliers, and can obtain advantageous component prices, making the price of the whole machine very competitive;

2. GoodCut aims to develop long-term cooperation with new and old customers, and give customers the best price with the most sincere attitude.

good service

1. English manual and video for machine use and maintenance, explaining the operation steps in detail;

2. Professional after-sales service personnel provide 24-hour online service;

3. Provide free technical training and on-site factory operation teaching to eliminate customers' worries.