Hdpe 450-800mm Pe plastic pipe butt welding machine with low price

- $50.00 /set

- 1 set

- Henan Jiashang Plastic Industry Co., Ltd.

- Henan, China

- Mr LUKE SONG

| Welding materials: | Polyethylene PPR PVC | Welding range: | 160-315 |

| brand: | js | After warranty service: | Video technical support |

| aspect: | 160-315mm | payment terms: | L/C, Western Union, T/T |

| usage: | Welding HDPE pipe and fittings | Voltage: | 220V/380V |

| Key words: | Welding machine | Supply capacity: | 500 boxes per week |

| Packaging Details: | wooden box | Warranty: | 1 year |

| Power (kW): | 4.95-12 | Origin: | Henan, China |

| Mechanical test report: | not available | type: | Hydraulic butt welding machine |

| Weight (kg): | 200 kg | Local service location: | not any |

| Health status: | new | application: | Welding HDPE pipe and fittings |

| Package preview: | Showroom location: | not any | |

| port: | Tianjin, Qingdao, Shanghai | Video shipment inspection: | not available |

| pack: | wooden box | After-sales service provided: | On-site installation, commissioning and training, on-site maintenance and repair services, online support, video technical support |

| Processing: | awalia bay | Ambient temperature: | 25°C |

| Marketing Type: | New Products 2020 | product name: | HDPE butt welding machine |

| Solder area: | ≤ pipe wall thickness | frequency: | 50Hz/60Hz |

| color: | customer request | Applicable industries: | Building supplies stores, construction work, energy and mining |

Low price HDPE450-800mm pe plastic pipe butt welding machine

Model | HDC315 | ||||

Pipe size (mm) | 450-800mm | ||||

Heating plate maximum temperature | 250°C | ||||

Surface temperature deviation (170-250) | ±5℃ | ||||

Maximum Tolerance for Welded Connections | 0.3mm | ||||

Maximum working pressure hydraulic station | 6mpa | ||||

Operating Voltage | 220V | ||||

working frequency | 50-60 Hz | ||||

Motor power/hydraulic station voltage | 0.75KW/220V | ||||

Heating plate power/voltage | 3KW/220V | ||||

Planning Tool Motor Power/Voltage | 1.2KW/220V | ||||

total power | 4.95KW | ||||

Gross weight (kg) | 187.3KG | ||||

net weight | 154.8KG | ||||

total volume | 0.740 cubic meters | ||||

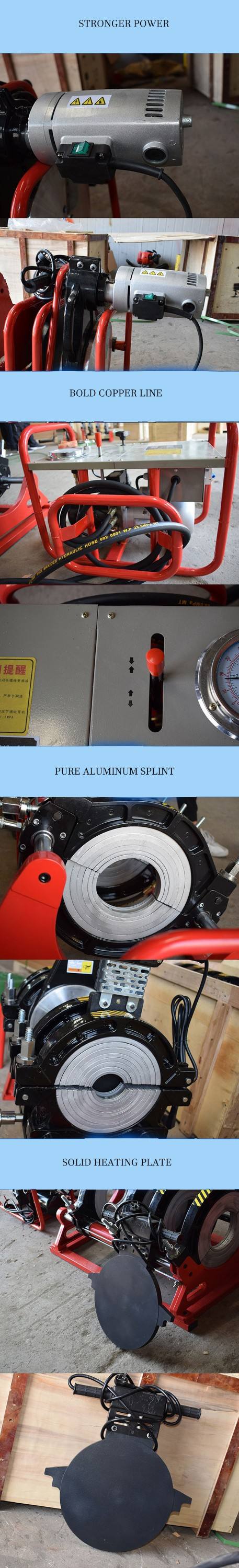

main body

The main body supports and centers the plastic tube with two fixed clamps and two movable clamps.

Using hydraulic pressure on the system, two pistons carrying metal rods move the clamp back and forth and provide the necessary motion for the welding process.

milling cutter

Milling cutters are tools used to clean and smooth the ends of pipes prior to the heating process.

The HDC160 Butt Welder is designed as a self-aligning end-facing machine, always producing parallel tube ends.

heater

The pipe ends will be heated by this heater before the welding process. The setting of the heater will be done by the thermostat on the board. HDC160 Butt Welding Machine adopts PTFE coated heating element, the surface temperature is uniform.

hydraulic device

Necessary electricity will be transferred! It is connected to the heater and milling cutter through the device, and is connected to the main machine through hydraulic pressure.

support

The protective case prevents heat loss from the heater and protects the trimmer from external influences.

application