High-performance magnetic materials OEM motor segment permanent magnets Strong sintered NdFeB new energy magnets

- $4.97 / 50 - 4999 pieces

$0.01 / >=5000 pieces - 50 pieces

- Anhui Magnet Technology Co., Ltd.

- Anhui, China

- Ms Ellie Cheng

PRODUCT DETAIL

| coating: | Ni+Cu+Ni, Zn, epoxy resin, Au, Ni+Cu+Ni+Cr, etc. | shape: | custom made |

| port: | Shanghai | test: | Salt spray test |

| Synthetic: | Neodymium magnet | place of origin; place of origin: | Anhui, China |

| product name: | Neodymium arc magnet | grade: | NdFeB |

| size: | custom size | Material: | NdFeB |

| Packaging Details: | Export standard carton comes with well protected foam. We can make packaging according to customer's requirements. | Processing service: | Bending, welding, uncoiling, cutting, punching, forming, sintering, bending, welding, uncoiling, cutting, forming |

| Operating temperature: | 80~220 degrees Celsius | delivery time: | 22-30 days |

| model: | N35-N52 | Supply capacity: | 2,000,000 pieces/month |

| Packaging Preview: | Established: | 2011 | |

| application: | industrial magnet | tolerant: | ±1% |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram | brand: | custom made |

| Quality system: | ISO 9001, IATF16949 | type: | Everlasting |

| Magnetic direction: | Customized specific requirements |

Product Description

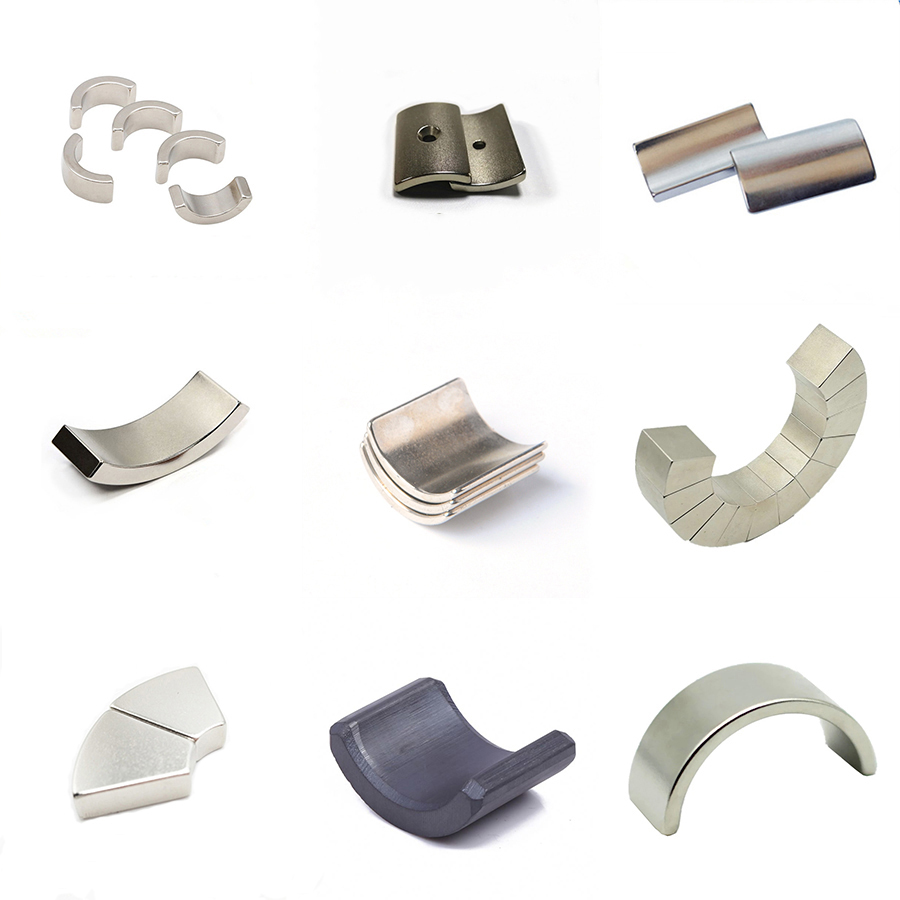

magnet shape

Neodymium grades

N35, N38, N42, N38SH... are neodymium magnet grades. As a very general rule, the higher the rating (the number after the "N"), the stronger the magnet. The highest grade of neodymium magnets currently available is N52. Any letter after the rating refers to the temperature rating of the magnet. If there is no letter after the grade, the magnet is standard temperature neodymium. Temperature ratings are standard (not specified) - M-H-SH-UH-EH. You can find the temperature rating for each grade on our Neodymium Magnet Specifications page.

Plating/Painting

There are various options for coatings, but nickel is the most common and usually preferred. Our nickel plated magnets are actually three layers of nickel, copper and nickel. This triple coating makes our magnets more durable than the more common single nickel plated magnets. Some other coating options are zinc, tin, copper, epoxy, silver and gold. Our gold plated magnets are actually quadruple nickel, copper, nickel and gold finish.

describe: | NdFeB magnets | ||||||

Material: | NdFeB | ||||||

product name: | NdFeB magnets, sintered rare earth magnets, NdFeB magnets, permanent magnets | ||||||

Serving temperature: | grade | temperature | |||||

N28-N48 | 80ºC | ||||||

N50-N55 | 60ºC | ||||||

30M-52M | 100℃ | ||||||

28H-50H | 120ºC | ||||||

28SH-48SH | 150ºC | ||||||

28UH-42UH | 180ºC | ||||||

28EH-38EH | 200ºC | ||||||

28AH-33AH | 200ºC | ||||||

Magnet shape: | Discs, cylinders, blocks, rings, countersunk heads, segments, trapezoids and irregular shapes, etc. Custom shapes available | ||||||

Magnet coating: | Ni, Zn, Au, Ag, epoxy resin, passivation, etc. | ||||||

Very high resistance to demagnetization | |||||||

high energy size | |||||||

good ambient temperature | |||||||

fair price | |||||||

This material is corrosive and should be coated for maximum long-term energy output | |||||||

Low operating temperatures for thermal applications, but higher levels of heat-resistant materials are regularly introduced | |||||||

application: | Sensors, motors, automotive filters, magnetic mounts, speakers, wind turbines, medical equipment, etc. | ||||||

Production Process

R&D testing center

Testing Center

We have domestic leading permanent magnet material research and development and testing equipment, and can carry out the whole process testing ability of rare earth permanent magnet material research and development and preparation, and have an independent testing laboratory to ensure the high quality of products.

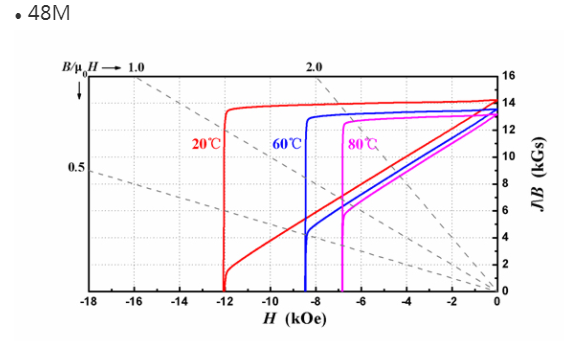

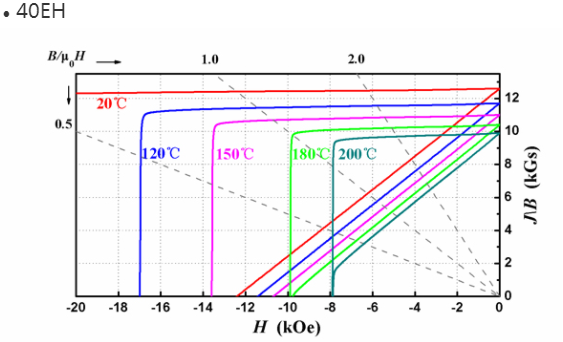

Demagnetization curve at your service

Demagnetization curves describe the magnetism of a magnet more completely than a single number such as tension or surface fields. It provides information on the strength of the magnet, the difficulty of demagnetization, and how the shape of the magnet affects the problem.

VIEW MORE

YOU MAY LIKE