High quality foundry chrome sand free sample for sale

- $530.00 / 1 - 99 pieces

$520.00 / 100 - 999 pieces

$500.00 / >=1000 pieces - 1 piece

- Henan Abrasivestocks Technology Co., Ltd.

- Henan, China

- Mr Andy Song

| Iron oxide: | Maximum 26.5% | port: | Shanghai/Tianjin/Qingdao |

| type: | my mine | size: | According to customer's request |

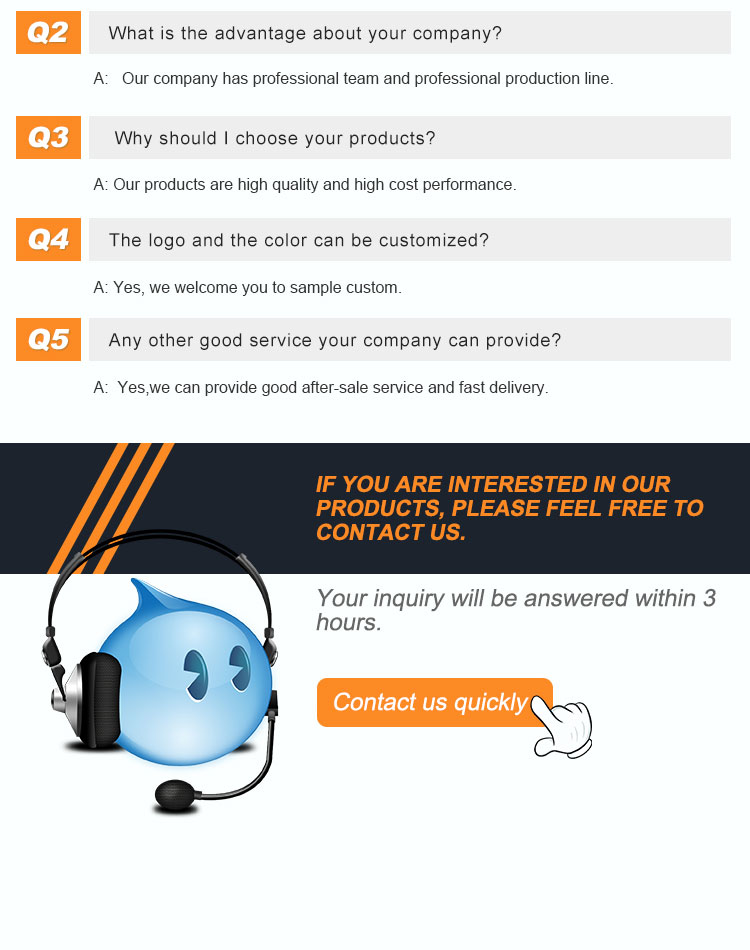

| chemical composition: | Cr2O3 46% minimum | Packaging Details: | 25kg per barrel, 500kg per pallet |

| brand: | stock | Supply capacity: | 1000 tons per month |

| Origin: | Henan | Package preview: | |

| Bulk density: | 2.5-3 g/cm3 | payment terms: | L/C, Western Union, D/P, D/A, T/T |

| pH: | 7-9 | Concentrated or not: | Whether to concentrate |

| Moisture (%): | 0.2% MAX, 0.1% max | Cr2O3%: | Minimum 46.0% |

| Cr2O3 (minimum): | 46%min | color: | Black |

| model: | CS45 CS35 | chemical composition: | Cr2O3 46% minimum |

Chrome ore

Chromite sand is a special sand for foundry. It is a natural spinel mainly composed of chromite. After crushing, grinding, and screening, it is divided into specified particle sizes, which is suitable for molding (core making) sand. Chromium ore can be divided into primary Cr2O3 (>45%) and secondary Cr2O3 (>35%) according to chemical composition.

feature:

1. Heating volume stability

2. High thermal conductivity

3. Strong alkali resistance

4. Solid phase sintering, non-sticky sand

Advantages of chromite sand

Compared with silica sand, chromite sand can avoid most of the sand sticking to the casting, so it can also save the cost of surface preparation. Additionally, chromite can be recycled multiple times for use in different technologies.

Technical data sheet:

| chemical composition | |

| Chromium trioxide | ≥46.0% |

| silica | ≤1.0% |

| iron oxide | ≤26.5% |

| Calcium Oxide | ≤0.3% |

| magnesium oxide | ≤10% |

| Aluminum oxide | ≤15.5% |

| P | ≤0.003% |

| small | ≤0.003% |

| Chromium/Fe | 1.55:1 |

| Typical Physical Properties | |

| hardness: | Mohs: 5.5-6 |

| Melting point: | Sublimation at 2180℃ |

| Sintering point: | >1800℃ |

| Sintered | 1600℃ |

| proportion: | 4.0-4.8 g/cm3 |

| Bulk Density (LPD): | 2.5-3 g/cm3 |

| color: | Black |

| pH | 7-9 |

| Percentage of free acid in sand | 0% |

| amount of acid | ≤2ML |

| soil percentage | ≤0.1 |

| Moisture percentage | ≤0.1 |

| available size | |

|

Less than 500KGS

|

500-1000KGS |

1-10 tons |

10-30 tons |

30-100 tons |

|

40-70 |

45-50 |

45-50 |

40-45 years old |

35-40 |