High quality pyramid shape, plastic slide media, surface that slides with scratch

- $25.00 / >=10 bags

- 10 bags

- Dongguan Zhentai Grinding Materials Co., Ltd.

- Guangdong, China

- Ms Angela Zhang

PRODUCT DETAIL

| usage: | grinding and polishing | model: | abrasive material |

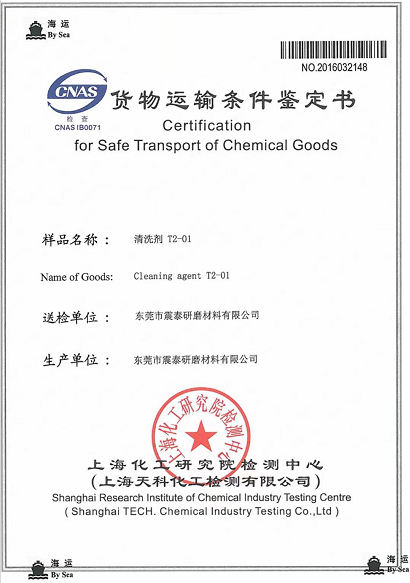

| Certification: | GS | brand: | Zhentai |

| type: | blasting medium | Abrasive material: | abrasive material |

| Packaging Details: | Export case | Package preview: | |

| Gross weight per piece: | 25.000 kg | Abrasive size: | 120 |

| Warranty: | 1 year | Origin: | Guangdong, China |

| Sales unit: | single product | Single pack size: | 60X40X10 cm |

Product overview

A series of grinding and polishing materials such as grinding stones, polishing stones, stainless steel balls, etc.

Abrasives can be simply divided into: brown corundum grinding stones, plastic resin grinding stones, high-alumina ceramic grinding stones, high-frequency ceramic grinding stones, steel ball grinding stones, etc.

1. Brown corundum grinding stone is mainly made of brown corundum sand and clay sintered at high temperature. Because the particle size of the grinding sand is 80-120, it has a strong grinding ability. Therefore, the grinding stone of this material is mainly suitable for rough polishing. It can quickly remove burrs, edges and scales on the surface of the workpiece. The brown corundum grinding stones produced by our company are spherical, cylindrical, cylindrical, triangular, triangular, etc. Sizes can be produced from 2mm to 50mm. Customers can choose the appropriate grinding stone according to the shape and size of the workpiece, so as to achieve the desired perfect effect. Special shapes and specifications can be made on request.

2. High-alumina porcelain polishing stone is mainly made of alumina powder and clay sintered at high temperature. Because the abrasive grain size is 1200, the structure is dense and the hardness is high, so the grinding stone of this material is mainly suitable for fine polishing. Used in conjunction with the brightener produced by our company, it can greatly improve the brightness of the workpiece surface. The high-alumina grinding stones produced by our company are spherical, meta-cylindrical, oblique meta-cylindrical, triangular, oblique triangular, etc. Sizes can be produced from 1mm to 50mm. Customers can choose the appropriate grinding stone according to the shape and size of the workpiece, so as to achieve the desired perfect effect. Special shapes and specifications can be customized according to customer requirements.

3. The main component of the plastic grinding stone is a mold made of plastic (ie resin) and quartz sand bonded in a certain proportion. It is mainly used to remove parting lines and burrs on the surface of alloy metal workpieces. The main shapes of plastic grinding stones are conical and triangular. Spot spare specifications: 10*10 to 65*65mm.

4. Steel balls (steel balls) can be simply divided into three types: low-carbon steel, high-carbon steel and stainless steel according to their materials. They are mainly used for polishing aluminum alloy, stainless steel and other products. Generally, there are round (commonly used diameter 2MM-----10MM) and butterfly (commonly used sizes 3MM*5MM, 4MM*6MM, 5MM*7MM,).

1. Brown corundum grinding stone is mainly made of brown corundum sand and clay sintered at high temperature. Because the particle size of the grinding sand is 80-120, it has a strong grinding ability. Therefore, the grinding stone of this material is mainly suitable for rough polishing. It can quickly remove burrs, edges and scales on the surface of the workpiece. The brown corundum grinding stones produced by our company are spherical, cylindrical, cylindrical, triangular, triangular, etc. Sizes can be produced from 2mm to 50mm. Customers can choose the appropriate grinding stone according to the shape and size of the workpiece, so as to achieve the desired perfect effect. Special shapes and specifications can be made on request.

2. High-alumina porcelain polishing stone is mainly made of alumina powder and clay sintered at high temperature. Because the abrasive grain size is 1200, the structure is dense and the hardness is high, so the grinding stone of this material is mainly suitable for fine polishing. Used in conjunction with the brightener produced by our company, it can greatly improve the brightness of the workpiece surface. The high-alumina grinding stones produced by our company are spherical, meta-cylindrical, oblique meta-cylindrical, triangular, oblique triangular, etc. Sizes can be produced from 1mm to 50mm. Customers can choose the appropriate grinding stone according to the shape and size of the workpiece, so as to achieve the desired perfect effect. Special shapes and specifications can be customized according to customer requirements.

3. The main component of the plastic grinding stone is a mold made of plastic (ie resin) and quartz sand bonded in a certain proportion. It is mainly used to remove parting lines and burrs on the surface of alloy metal workpieces. The main shapes of plastic grinding stones are conical and triangular. Spot spare specifications: 10*10 to 65*65mm.

4. Steel balls (steel balls) can be simply divided into three types: low-carbon steel, high-carbon steel and stainless steel according to their materials. They are mainly used for polishing aluminum alloy, stainless steel and other products. Generally, there are round (commonly used diameter 2MM-----10MM) and butterfly (commonly used sizes 3MM*5MM, 4MM*6MM, 5MM*7MM,).

about Us

Zhentai company takes "integrity, high quality, truth-seeking and innovation" as its business purpose, and adheres to the guidance of user needs

Goals, attach importance to customers' suggestions, and solve customers' problems in the grinding process at any time. us

Focus on shimmer and polish. We provide comprehensive design, development, production, consulting,

Sales, installation and commissioning, spare parts supply, technical training, etc. Welcome friends from all walks of life to patronize

Visit and negotiate business. We sincerely hope to provide the best quality and service for your company. Dongguan

Zhentai Abrasive Material Co., Ltd. - your reliable partner!

Goals, attach importance to customers' suggestions, and solve customers' problems in the grinding process at any time. us

Focus on shimmer and polish. We provide comprehensive design, development, production, consulting,

Sales, installation and commissioning, spare parts supply, technical training, etc. Welcome friends from all walks of life to patronize

Visit and negotiate business. We sincerely hope to provide the best quality and service for your company. Dongguan

Zhentai Abrasive Material Co., Ltd. - your reliable partner!

our certificate

Customer visit

customer training

Package&Boat

similar product

VIEW MORE