High quality sample-free reflective material micro glass beads reflective glass beads sandblasting road reflective glass beads

- $290.00 / 2 - 9 pieces

$280.00 / 10 - 19 pieces

$260.00 / >=20 pieces - 2 pieces

- Jinan Junda Industrial Technology Co., Ltd.

- Shandong, China

- Ms Dora Ding

PRODUCT DETAIL

| Origin: | Hebei china | payment terms: | Letter of credit, wire transfer |

| Refractive index: | Neodymium≥1.5% | brand: | Junda |

| port: | Tianjin | Wire diameter: | 0.03-0.4mm |

| Calcium Oxide: | >8% | Package preview: | |

| density: | 2.4-2.6 g/cm3 | special function: | bright |

| Packaging Details: | Glass beads for sandblasting 1) 25 kg/bag, 40 bags per ton. 2) 1000kg in one ton bags. 3) 25kg/bag, then 40 bags per pallet | round: | Roundness rate ≥95% |

| Durability: | 3-5% | type: | reflective glass beads |

| Silica: | >72% | product name: | Glass beads for sandblasting |

| Microhardness: | ≥650kg/cubic centimeter | Supply capacity: | 3,000 tons of glass beads for sandblasting per month |

| hardness: | 6-7 Mohs hardness; 46HRC |

Glass beads for sandblasting

Junda Glass Beads is a type of sandblasting used for surface finishing, specifically preparing metal by smoothing it. bead

Sandblasting provides superior surface cleaning, removing paint, rust, and other coatings. The glass bead sandblasting process is

Environmentally friendly and chemical-free, it can be used to detect welds and welding defects. Advantages of using glass bead blasting

Includes: • Multiple grades for different jobs and situations. • Will not interfere with coatings as it is non-reactive. • It leaves no residue or embedded contaminants and does not cause any dimensional surface changes. • Improved corrosion resistance and ability to eliminate surface defects. • No crystalline silica detected.

Sandblasting provides superior surface cleaning, removing paint, rust, and other coatings. The glass bead sandblasting process is

Environmentally friendly and chemical-free, it can be used to detect welds and welding defects. Advantages of using glass bead blasting

Includes: • Multiple grades for different jobs and situations. • Will not interfere with coatings as it is non-reactive. • It leaves no residue or embedded contaminants and does not cause any dimensional surface changes. • Improved corrosion resistance and ability to eliminate surface defects. • No crystalline silica detected.

how it worksJunda glass bead blasting essentially uses fine glass beads of various sizes under different pressures. Smaller glass spheres produce a smoother surface, while larger glass spheres produce a more textured surface. Glass beads will not remove any base metal or embedded surface. It will produce a better, more even finish while also adding shine or brightness to the part. It has a variety of applications, including: • Finishing: Can be used on a variety of materials, including metal, glass, plastic and rubber. • Cleaning: Glass bead blasting removes/cleans foreign matter without causing surface dimensional changes. • Deburring: In order to assemble and manipulate parts, corners and edges may need to be deburred. Glass bead blasting removes burrs and rough edges while ensuring that base metal from the surface is not removed. • Shot Peening: Shot peening can extend the life of metal components by fighting stress cracks and corrosion.

Junda road sign glass beads are small glass beads formed from glass sand and waste glass as raw materials and melted at high temperature. They are spherical, colorless and transparent under the microscope, with a diameter between 75 microns and 1400 microns. Currently, they mainly produce road reflective glass. The microbead process is flame floating method.

Junda road marking glass beads are mainly used in normal temperature and hot-melt road marking coatings. First, as a premixed material, it can ensure the reflectivity of the marking during its service life. Second, it can be spread on the marking construction surface. , can have a reflective effect.

Glass microbeads use a high-performance, organic material on the outside of the glass microbeads to reduce the adsorption of dust in the air on the surface of the glass microbeads. Because the glass microbeads contain a specific coupling agent, the performance of the glass microbeads is improved. and performance. The cohesion of the coating can prevent some tiny glass beads from adhering to the coating. Due to its floatable function, when using a coating that floats on the surface, it has a large surface area and can increase the utilization rate by more than 30%. Reflective glass beads have now become an irreplaceable reflective material in road safety products.

We can provide glass beads with different refractive indexes such as 1.53, 1.72, 1.93, etc. We can also provide glass beads of various national standards, or according to the particle size distribution provided by the customer.

We provide the following standard glass beads Chinese standard: GB/T 24722-2009 No.1, 2, 3; Korean standard: KSL 2521 No.1 and 2; British standard: BS6088 Grade A and B; American standard: AASHTO M247 1 Type and type 2; European standards: EN1423 and EN1424; Turkish standards: TS EN1423; New Zealand standards: NZS2009:2002; Taiwan standards: CNS; Japanese standards: JIS R3301; Australian standards Australian standards: A, B, C, D.

Ground glass beads Junda ground glass beads are glass beads with uniform particle size, smooth surface, high hardness and good chemical stability. Grinding beads are generally glass beads with a particle size greater than 1 mm. They are colorless and transparent in appearance and are clean spheres. It is widely used as dispersant, grinding media and filling material in dye, paint, ink, chemical and other industries. We can provide sizes of 0.8, 1.2, 1.0, 1.5, 1.5, 2.0, 2.0, 2.5, 2.5, 3.0, 3.0, 3.5 mm, or according to customer requirements.

Application 1. Welding beads strike aviation parts to eliminate their stress, enhance fatigue strength, and reduce friction and wear; 2. Anodizing and pre-plating processing, and cleaning can increase adhesion; 3. Weld bead cleaning and surface demarking of stainless steel workpieces Beautiful treatment such as marks; 4. Cleaning and rust removal of wire cutting molds; 5. Descaling of rubber molds;

project | quality | ||

chemical composition% | silica | >72% | |

Calcium Oxide | >8% | ||

sodium oxide | <14% | ||

magnesium oxide | >2.5% | ||

Aluminum oxide | 0.5-2.0% | ||

Ferric oxide | 0.15% | ||

others | 2.0% | ||

refractive index | Neodymium≥1.5% | ||

density | 2.4-2.6 g/cm3 | ||

size distribution | Large size ≤ 5% Small size ≤ 10% | ||

Wire diameter | 0.03-0.4mm | ||

Durability | 3-5% | ||

hardness | 6-7 Mohs hardness; 46HRC | ||

Microhardness | ≥650kg/cubic centimeter | ||

round | Roundness rate ≥95% | ||

appearance | Colorless, transparent glass without impurities, round and smooth | ||

application | 1. Polishing 2. Road marking paint 3. Sand blasting | ||

Lead content | Lead-free content, meeting the US 16CFR 1303 lead content standard | ||

Hazardous substance content | Lower than US 16CFR 1500 standard | ||

Flammability fire test | Not easy to burn, meets the US 16CFR 1500.44 standard | ||

Soluble heavy metal content | Metal content, soluble matter ratio, solid weight ratio does not exceed the corresponding value of ASTM F963 | ||

pack | 25KG/pp bag then 40 bags one ton bag/pallet | ||

standard | EN1423, 1424; AASHTO, M247; BS6088; JISR3301; KS L2521, etc. | ||

Glass beads----Application

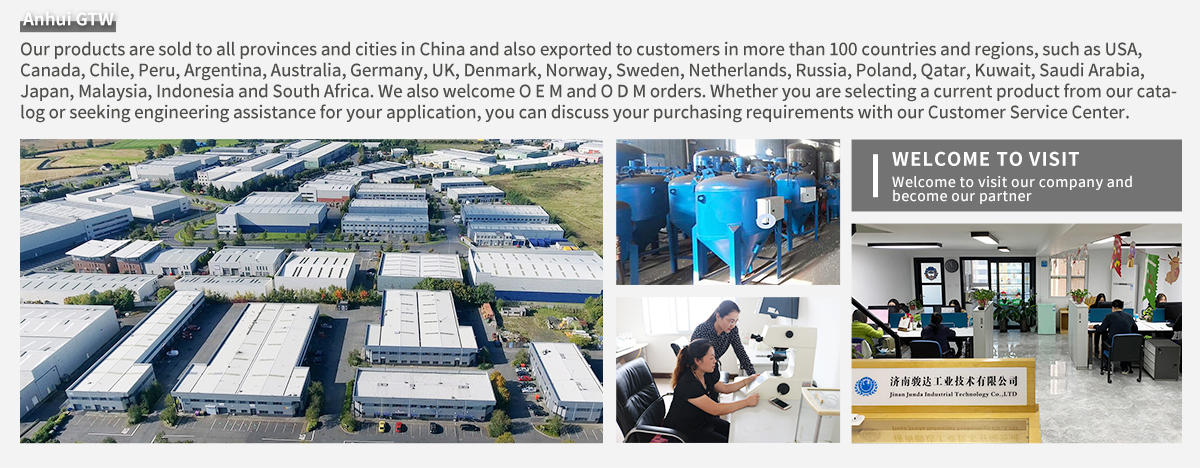

1. We work with governments around the world to improve road safety.

2. With our ongoing research into retroreflectivity and our industry-leading technical service team, our leadership and innovation set the standard for reflective highway markings.

3. The global acceptance of these safety standards has resulted in global demand for reflective marking materials.

4. Currently, more than two-thirds of our annual global production (the single largest use of our products worldwide) is used in highway delineation and guidance systems.

1. We work with governments around the world to improve road safety.

2. With our ongoing research into retroreflectivity and our industry-leading technical service team, our leadership and innovation set the standard for reflective highway markings.

3. The global acceptance of these safety standards has resulted in global demand for reflective marking materials.

4. Currently, more than two-thirds of our annual global production (the single largest use of our products worldwide) is used in highway delineation and guidance systems.

Packaging and shipping

Our packages

1.25kg/bag (PP bag or paper bag) then 40 bags per ton bag/pallet,

2. One ton and one bag

All packaging is lined with waterproof material

We can also package according to your requirements.

Our packages

1.25kg/bag (PP bag or paper bag) then 40 bags per ton bag/pallet,

2. One ton and one bag

All packaging is lined with waterproof material

We can also package according to your requirements.

Q: What is the payment method?

T/T: 50% advance payment, the remaining 50% payment is paid to us when receiving the scanned B/L from our email

L/C: 100% irrevocable letter of credit at sight

Q: What is the minimum order quantity of your products?

As usual, MOQ is 5 tons. Or based on your request, we need to calculate a new price to you.

Q: Can you provide free samples?

Yes, we can send you free samples below 500 grams.

Q: What standards do your products implement?

SAE standards and ISO 9001, SGS

T/T: 50% advance payment, the remaining 50% payment is paid to us when receiving the scanned B/L from our email

L/C: 100% irrevocable letter of credit at sight

Q: What is the minimum order quantity of your products?

As usual, MOQ is 5 tons. Or based on your request, we need to calculate a new price to you.

Q: Can you provide free samples?

Yes, we can send you free samples below 500 grams.

Q: What standards do your products implement?

SAE standards and ISO 9001, SGS

VIEW MORE

YOU MAY LIKE

Other Products

-

Quality guaranteed white quartz sand pure quartz sand filter material water filter quartz sand$95.00 - $120.00 / piece

Quality guaranteed white quartz sand pure quartz sand filter material water filter quartz sand$95.00 - $120.00 / piece