ISO2531 DN100 DN200 DN300 DN900 ductile iron pipe K9 good quality

- $600.00 / 40 - 99 pieces

$570.00 / 100 - 199 pieces

$530.00 / >=200 pieces - 40 pieces

- Shandong Hongqiao Energy Equipment Technology Co., Ltd.

- Shandong, China

- Mr Gavin Hao

PRODUCT DETAIL

| hardness: | 230HB | port: | Shanghai, Qingdao, Tianjin, Guangzhou, Ningbo Port |

| transportation: | Bulk ship or container | Inscription style: | Customer requirements |

| Material: | Ductile Iron | Connector type: | T type |

| Key words: | Ductile iron pipe cap | standard: | ISO2531/EN545/EN598, ISO2531/EN545/EN598 |

| Place of origin: | Shandong Province, China | brand: | Hongqiao |

| External coating: | Galvanizing, asphalt paint or epoxy paint, etc. | Package preview: | |

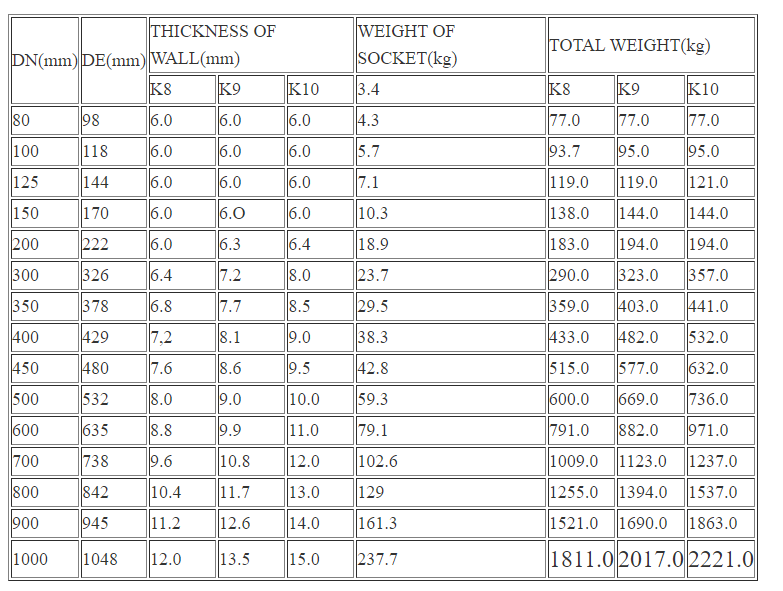

| model: | DN100-DN2000 | Pipe wall thickness: | K7/K8/K9/C40/C30/C25 |

| Inner coating: | Mortar cement lining | Packaging details: | Standard export airworthy packaging. Suitable for all kinds of transportation, or as needed |

| Certification: | ISO9001:2000 | Supply capacity: | 50,000 tons per month |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Surface treatment: | black paint |

| shape: | round | application: | Drinking water/sewage |

| Yield strength (≥MPa): | 600 | Processing services: | Welding, bending, punching, uncoiling, cutting |

| product name: | EN545 /ISO2531/EN598 Ductile Iron Pipe | type: | casting |

| test: | 100% water pressure tested | length: | Customer requirements |

| pull: | 420 MPa |

Product parameters

Name | Ductile iron water supply pipe |

Material | C, Si, Mn, P, S, Mg |

length | 6m or customized |

color | black red |

Advantage | Anti-corrosion; various types; anti-penetration; anti-aging; good durability |

processing | Asphalt outer layer, cement mortar lining |

pricing term | Ex-factory price, FOB, CNF, CFR, CIF, FCA, DDP, DDU, etc. |

expiration of pay | T/T, L/C, Western Union |

delivery time | 7-15 days after receiving T/T or L/C deposit |

Advantages: anti-corrosion; various types; anti-penetration; anti-aging; good durability

Processing of exterior coating with asphalt and interior lining with cement mortar

1.Standards: ISO2531, EN545, EN598, ANSI/AWWA, C151/A21

2. Effective length: 6m/5.5m

3. Lining: ordinary Portland cement, sulfate-resistant cement, high alumina cement.

4. Outer coating: zinc primer plus asphalt or epoxy coating

5. Transportation: bulk carrier or 20'/40' container

6. Rubber: NBR, SBR, EPDM conform to ISO4633/EN681.1

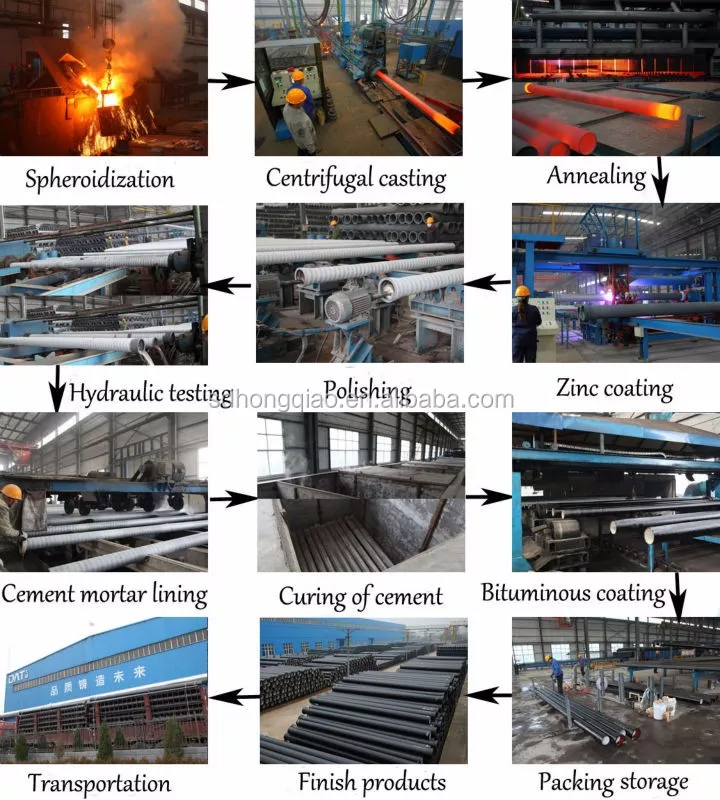

Processing of exterior coating with asphalt and interior lining with cement mortar

1.Standards: ISO2531, EN545, EN598, ANSI/AWWA, C151/A21

2. Effective length: 6m/5.5m

3. Lining: ordinary Portland cement, sulfate-resistant cement, high alumina cement.

4. Outer coating: zinc primer plus asphalt or epoxy coating

5. Transportation: bulk carrier or 20'/40' container

6. Rubber: NBR, SBR, EPDM conform to ISO4633/EN681.1

Product Details

Ductile iron pipe 1. The pipe produced has good straightness, good wall thickness and good mechanical properties. 2. Use flexible quick-plug joints and rubber gaskets to facilitate the installation of centrifugally cast T-shaped ductile iron pipes. 3. Pipes are produced in accordance with ISO2531, EN545, and EN598 standards. 4. The pipeline is push-connected. Coated with zinc + asphalt paint, lined with cement mortar. 5. Gasket materials include NR, NBR, EPDM, etc.

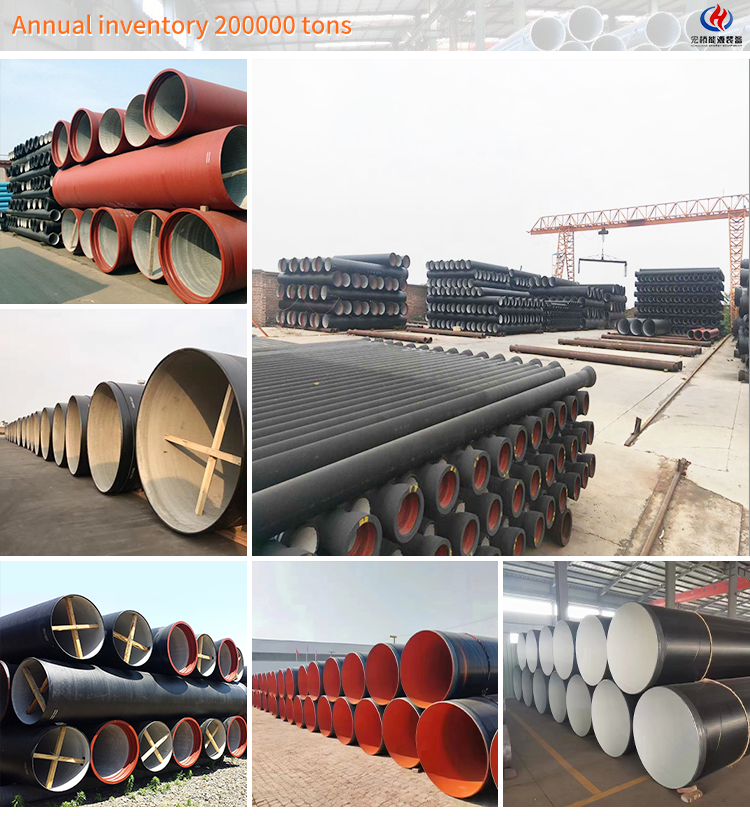

factory inventory

1. Internal pressure resistance: Centrifugal ductile iron has the essence of iron and the performance of steel, so ductile iron pipes have excellent safety performance than pipes made of other materials. The design working pressure is much higher than that of pipes made of other materials, and the safety factor is quite high. The possible burst pressure is three times the working pressure. 2. External pressure resistance: High external pressure resistance can eliminate the requirements for pipe beds and protective covers, making pipeline laying reliable and economical. 3. Inner anti-corrosion layer: The inner layer of ductile iron pipe is centrifugally sprayed with cement mortar. The cement lining complies with the international standard ISO4179, ensuring that the mortar is strong and smooth. The motor coating does not fall off, does not scale, and has a uniform thickness, ensuring that the drinking water transported by the pipeline is well protected. 4. Protective coating: Ductile iron pipes are sprayed with zinc, which actively protects the pipes through the electrochemical action of zinc and iron. With high chlorinated resin coatings, pipelines will receive enhanced anti-corrosion protection. The amount of zinc sprayed on the surface of each pipe is not less than 130g/m², which complies with ISO8179 standards. We can also increase the thickness of zinc spray or zinc spray aluminum alloy layer according to customer needs.

VIEW MORE

YOU MAY LIKE

Other Products

-

ISO 2531 ISO 9001 k9 Water supply system ductile iron pipe price per meter of water supply cast iron pipe$530.00 - $600.00 / piece

ISO 2531 ISO 9001 k9 Water supply system ductile iron pipe price per meter of water supply cast iron pipe$530.00 - $600.00 / piece -

dx51d z80 z120 z275 0.5mm 0.6mm 0.8mm color ppgi cold roll ppgi roll$400.00 - $700.00 / piece

dx51d z80 z120 z275 0.5mm 0.6mm 0.8mm color ppgi cold roll ppgi roll$400.00 - $700.00 / piece -

astm a276 s31803 stainless steel round rod/en24 steel round bar$1.40 - $3.50 / kilogram

astm a276 s31803 stainless steel round rod/en24 steel round bar$1.40 - $3.50 / kilogram