KAVO SR144TLKZNW High Speed Dental Handpiece Drill Holder R144ZZ SR144TLKZNW

- $0.10 / >=10 pieces

- 10 pieces

- Shandong XRT Bearing Co., Ltd.

- Shandong, China

- Ms Amy Zhang

| application: | Dental, Medical, Mobile, KAVO | Cage Type: | Torlon Phenolic Resin |

| Certificate: | ISO9001:2000 | Supply capacity: | 100000 pieces/month |

| Accuracy class: | P0 P6 P5 P4 P2 | Seal Type: | ZZ 2RS Open |

| sample: | available | payment terms: | L/C,T/T,Western Union,Paypal,Visa |

| size: | 3.175*6.35*2.78mm | Outer diameter: | 20 - 300 mm |

| Aperture: | 10 - 200 mm | Rows: | single row |

| type: | ball | Delivery Details: | Ships within 1 day after payment |

| product name: | Dental drill handpiece bearing SR144TLKZNW | brand: | XRT or OEM service |

| place of origin; place of origin: | Shandong China | price: | competitive price |

| Serve: | OEM customized service | weight: | 0.02g |

| structure: | Deep groove, ball bearing | port: | Qingdao, Ningbo, Guangzhou, Tianjin, Shanghai |

| Packaging Details: | High-speed dental handpiece bearing tube box marking: 1. Laser marking on the outer surface of the outer ring, such as the brand, 2. Printing the brand on the rubber/metal shield | model: | SR144TLKZNW |

KAVO SR144TLKZNW high speed dental handpiece dental drill bearing R144ZZ SR144TLKZNW

The company's high-speed dental drill bearing accuracy conforms to the national GB/T30701-2005P4 standard. The inner and outer rings are made of refined stainless steel vacuum heat treatment and cold treatment, and are produced with imported high-precision grade steel balls or imported super-hard ceramic ball materials. The cage is made of high-performance polyimide materials imported from the United States and processed and manufactured by CNC. After correctly assembled into a standard mobile phone, under the pressure of 200-250Kpa, the speed can reach 35-45 million revolutions per minute, and the normal life span can reach more than six months.

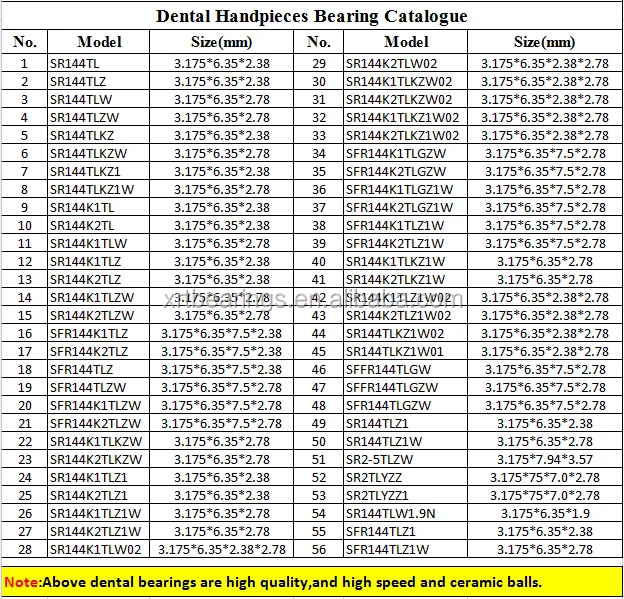

Dental Drill Bearings Catalog

KAVO SR144TLKZNW high speed dental handpiece dental drill bearing R144ZZ SR144TLKZNW picture

Precautions for the use and installation of high-speed dental handpiece bearings

Precautions for the use and installation of high-speed dental handpiece bearings

1. The interference fit between the bearing hole and the turbine shaft is preferably below 0.5μm-1.5μm. When placing the turbine shaft into the bearing hole, pressure should be applied to the inner ring surface to avoid damage to the raceways and balls.

2. The bearings installed behind the turbine shaft and the turbine shaft and turbine shaft bearings should be cleaned and dripped with special lubricating oil, and should not be cleaned with ethanol and acetone.

3. After the dental high-speed handpiece has been sterilized by high pressure steam, some lubricant should be sprayed at the air inlet before use to prolong the service time of the bearing.

4. In order to ensure the stability of the bearing during high-speed operation, the bearing pressure should be controlled at 1.2±02.N.

Dental drill bearing application

We specialize in the production of ball bearings, roller bearings and linear bearings for more than 10 years. Please contact us,

Therefore, we can help you choose the best and competitive prices to suit your needs and fit your budget!