Large capacity 2000 kg/hour PET plastic bottle recycling washing line

- $60000.00 / 1 - 4 sets

$58000.00 / >=5 sets - 1 set

- Jiangsu Mooge Machine Co., Ltd

- Jiangsu, China

- Mr Michael Huang

| Package preview: | Core components: | PLC, bearings, motors, gears | |

| Mechanical test report: | if | thermometer: | Omron |

| Voltage: | 380V 50HZ | Production capacity (kg/hour): | 300 - 5000 |

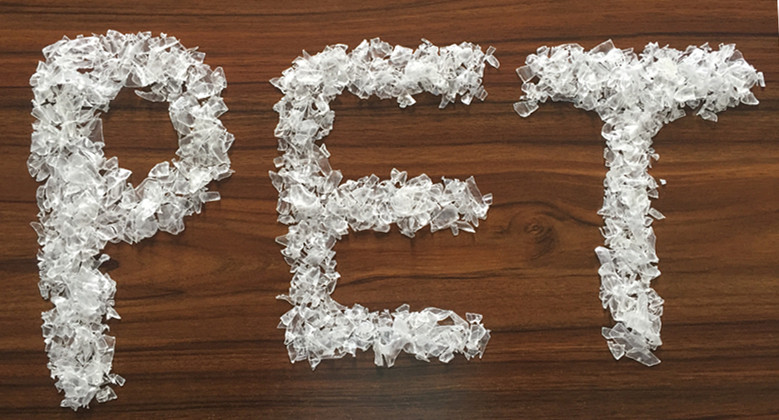

| payment terms: | L/C, Western Union, D/P, T/T | Finished goods: | Clean PET flakes |

| type: | PET bottle plastic recycling line | Plastic Type: | pet |

| Video shipment inspection: | if | Inverter: | delta |

| Weight (ton): | 20 | capacity: | 300/500/1000kg/hour |

| brand: | Mog Technology | Type of machine: | PET bottle washing line |

| Maximum production capacity (kg/h): | 5000 | raw material: | PET bottle waste |

| Automatic level: | automatic | service system: | online support |

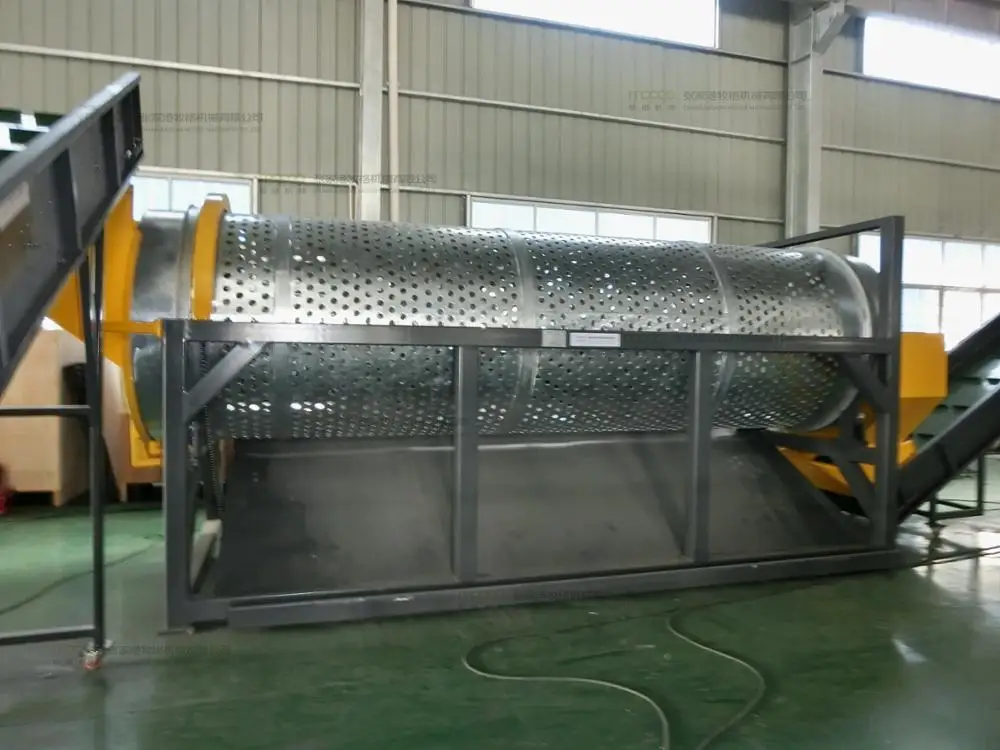

| Showroom location: | Egypt, Turkey, United Kingdom, Brazil, Peru, India, Mexico, Russia, Thailand, South Korea, Bangladesh | Equipment List: | Drum washing machine, pre-washing machine, bag unpacking machine, dehydrator, floating washing tank, hot air dryer, friction washing machine, label dividing machine, label removing machine, hot washing tank |

| Origin: | Jiangsu, China | Health status: | new |

| Dimensions (L*W*H): | 30m*2m*3m | Packaging Details: | Standard export packaging |

| Main selling points: | high security level | port: | Shanghai |

| application: | PET bottle recycling | After-sales service provided: | Engineers available to service machinery overseas |

| Core component warranty: | 1 year | Hot sink: | Elective |

| Supply capacity: | 5 sets per month | Power (kW): | 450 |

| After warranty service: | Video Technical Support | Warranty: | 1 year |

| Applicable industries: | Manufacturing plants, plastic recycling plants |

Large capacity 2000kg/hr PET bottle recycling washing line

Please select the capacity model you want;

We can manufacture production lines according to customer requirements and final sheet quality requirements;

Model | capacity | Installed power | water supply | Area requirements |

MT-500 | 500 kg/h | 125KW | 4-5 cubic meters per hour | 55*3.5*4.5m |

MT-1000 | 1000 kg/h | 185KW | 5-6 cubic meters per hour | 55*6*3.5m |

MT-2000 | 2000 kg/h | 325KW | 10-12 cubic meters per hour | 80*6*5m |

MT-3000 | 3000 kg/h | 600KW | 20-30 cubic meters per hour | 100*8*5 meters |

MT-5000 | 5000 kg/h | 1000KW | 40-50 cubic meters per hour | 135*8*6.5m |

main feature

1. We have unpacking and feeding system, uniform feeding and labor-saving;

2. You can use the manual sorting system to pick out bottles of different colors and non-PET materials;

3- Metal detector is optional for removing any kind of metal from PET bottle;

4- The specially designed PET bottle crusher can easily obtain high output, and wet grinding with water can prolong the service life of the blade and reduce dust generation;

5- High-speed dehydrator and drying system can ensure the final PET flake moisture <1%.

6-Fin deduster will remove the final label from the sheet to guarantee the PVC content.

Unpacking system—the unpacking machine breaks up the bottle packs into loose bottles (optional) Four-axis design improves efficiency

Label removal machine——separate labels and partial caps from plastic bottles, work with water, and the label separation rate is as high as 95%

Dry or Wet Crusher - Crushes plastic bottles into flakes. V-shaped rotor for higher throughput and lower power consumption

Hot and cold washing tank - material cleaning and density separation. Automatic running of drums increases efficiency

Chemical Thermal Sink - Removes grease and glue. Add caustic soda/detergent to wash, electric heating or customized

Friction cleaning machine - scrubbing of materials. Speed: 1440RPM or 1500RPM, fast speed and good performance

High Speed Dehydrator - Removes moisture from products. The same design as the friction cleaner, the moisture residue will be less than 1%

Hot air drying system - reduce the moisture content of the finished product. Drying the final flakes by electric heating and blowing the flakes into the silo

Other Products

-

pet bottle bale breaker machine$14000.00 - $15000.00 / set

pet bottle bale breaker machine$14000.00 - $15000.00 / set -

pet bottle bale breaker machine$14000.00 - $15000.00 / set

pet bottle bale breaker machine$14000.00 - $15000.00 / set