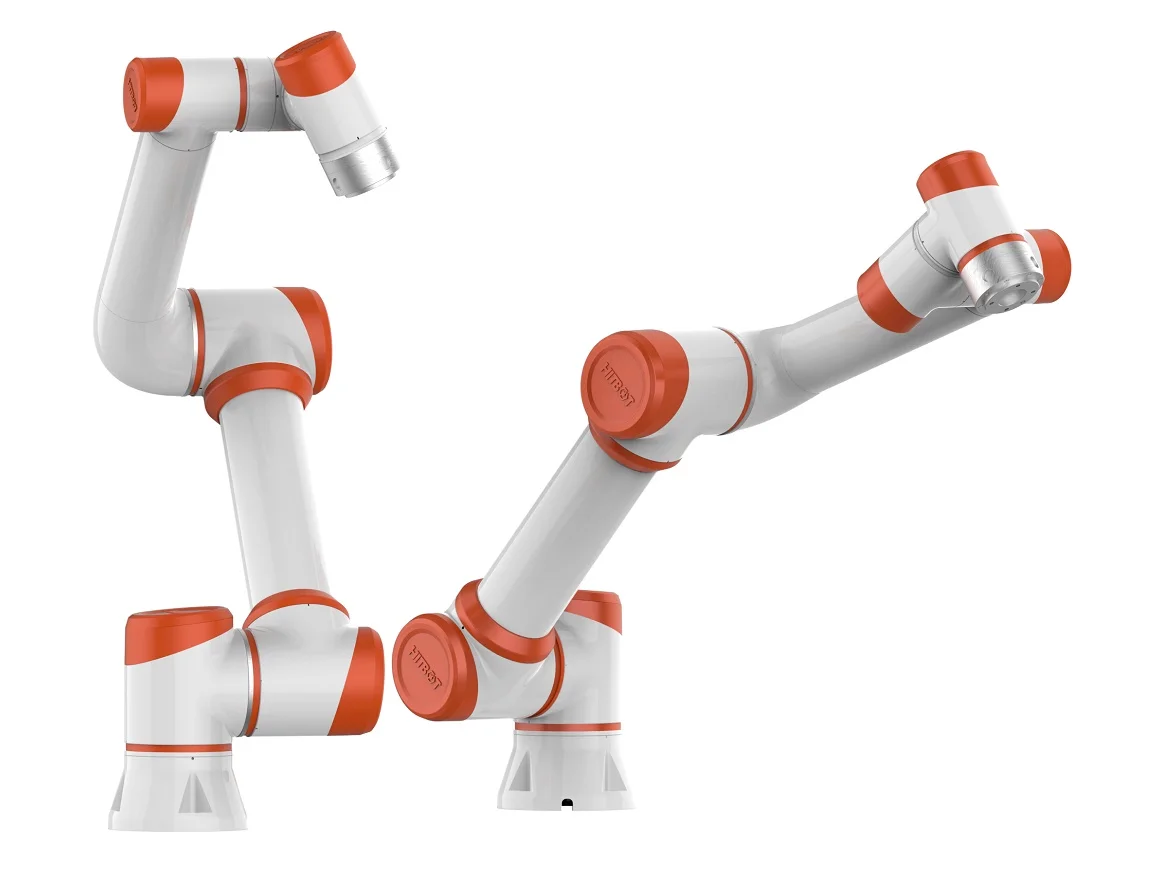

Low Cost Hitbot Industrial Manipulator Coffee Making Robot Arm Robot Hand 4 Axis Robot Arm For Industrial Smart Manufacturing

- $9000.00 / 1 - 49 pieces

$6000.00 / >=50 pieces - 1 piece

- Huiling-Tech Robotic Co., Ltd.

- Guangdong, China

- Mr Simon Chen

PRODUCT DETAIL

| Single package size: | 830X480X490 cm; | Warranty of core components: | 1 Year; |

| Selling Units: | Single item; | Noise: | <60dB; |

| Warranty: | One year; | Weight (KG): | 19; |

| Application: | For assembly, dispensing, screwdriving,; | Core Components: | PLC,Gearbox,Motor; |

| Power: | /; | Payload: | 5kg; |

| Single gross weight: | 46.000 KG; | Machinery Test Report: | Provided; |

| Showroom Location: | Canada,United States,Italy,Germany,Brazil,Peru,Saudi Arabia,Indonesia,Pakistan,India,Mexico,Russia; | Speed: | ±180°/s; |

| Degree of Freedom: | 6; | Repeatability: | ±0.1mm; |

| Voltage: | 220V/50Hz; | Brand Name: | HITBOT; |

| Marketing Type: | New Product 2021; | Dimension(L*W*H): | Footprint 150mm; |

| Reach: | 922mm; | Applicable Industries: | Hotels,Garment Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Food & Beverage Shops,Other; |

| Place of Origin: | Jiangsu, China; | Video outgoing-inspection: | Not Available; |

| Condition: | New; | Packaging Detail: | Box; |

| Weight: | 18.5kg; | Features: | Collaborative; |

| Production Capacity: | 20000 pieces/year; | Footprint: | 150mm; |

| IP classification: | IP54; | Product model: | Z-Arm S922; |

| Package Preview: | ; |

Product Overview

Easy Programming

How to easily program a robot even without coding skills and robotics knowledge? Don't worry, HITBOT Z-Arm S922 is quite clever at learning. Simply drag and drop its arm to the desired position, or use graphical blocks in the APP, HITBOT Z-Arm S922 will quickly remember and follow the exact path. The whole intuitive programming process only takes several minutes.

Quick Deployment

Compact and light, HITBOT Z-Arm S922 has its reducer, motor, encoder, and drive controller integrated as a whole, which greatly improves the convenience of installation and redeployment.

Flexible Application

Designed to handle payloads up to 5KG, HITBOT Z-Arm S922 can be trusted by different industries, such as automotive, electronics, food and beverage, healthcare and lab research, for various applications, like assembly, pick and place, screwdriving, dispensing, and gluing. As long as you have demands, HITBOT Z-Arm S922 can help you achieve in action.

Designed to handle payloads up to 5KG, HITBOT Z-Arm S922 can be trusted by different industries, such as automotive, electronics, food and beverage, healthcare and lab research, for various applications, like assembly, pick and place, screwdriving, dispensing, and gluing. As long as you have demands, HITBOT Z-Arm S922 can help you achieve in action.

Trusted Safety

HITBOT Z-Arm S922 is human-friendly. Even without fences, it can be deployed to work alongside people as it supports collision detection control. Operators can move freely around the robot without concerns for their safety or impacting production. HITBOT Z-Arm S922 helps you to create quite a safe working environment.

HITBOT Z-Arm S922 is human-friendly. Even without fences, it can be deployed to work alongside people as it supports collision detection control. Operators can move freely around the robot without concerns for their safety or impacting production. HITBOT Z-Arm S922 helps you to create quite a safe working environment.

Product Display

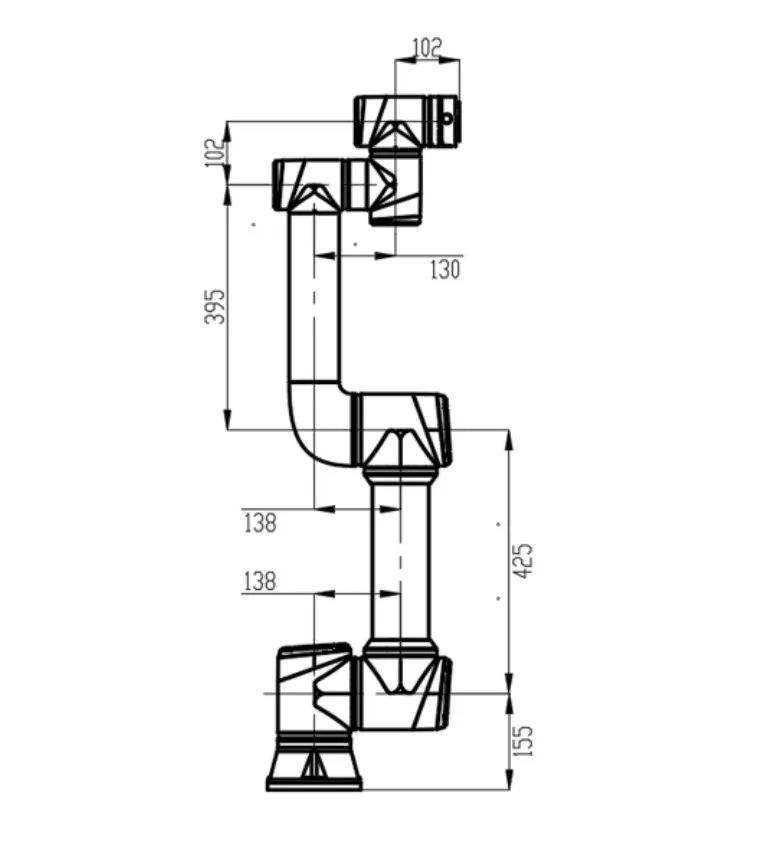

Size Diagram

PRODUCT SPECIFICATIONS

Model | Z-arm S922 | ||

Number of axis | 6 | ||

Maximum payload | 5KG | ||

Weight | 18.5KG | ||

Maximum reach | 922mm | ||

J1 rotation (1-axis) | ±175° | ||

J2 rotation (2-axis) | +85°,-265° | ||

J3 rotation (3-axis) | ±160° | ||

J4 rotation (4-axis) | +85°,-265° | ||

J5 rotation (5-axis) | ±175° | ||

J6 rotation (6-axis) | ±175° | ||

Speed | ±180°/s | ||

Repeatability | ±0.1mm | ||

Footprint | ±150mm | ||

IP classification | IP54 | ||

Noise | Less than 60dB | ||

End DI/DO ports | Digital input: 2 | Digital output: 2 | |

End AI/AO ports | Analog input: 1 | Analog output: 1 | |

Control box DI/DO ports | Digital input: 16 | Digital output: 16 | |

Control box AI/AO ports | Analog input: 2 | Analog output: 2 | |

I/O power supply | 24V/2A | ||

Power intput | 220V/50Hz | ||

Operating temperature | 0-45℃ | ||

Humidity | 90%RH (non-condensing) | ||

Teach pendant | Drag to Teach / Jog mode | ||

Communication | TCP | ||

Collision detection | Supported | ||

Collaboration | Collision detection (with custom collision level supported) | ||

SALES AND SERVICE NETWORK

Company Profile

Established in 2015, HITBOT is 5-year experienced collaborative robot manufacturer, mainly specializing in designing and producing light-weight table-top collaborative robot and electric robot grippers.

With over 10 years of technology research and development, HITBOT has successfully lowered the threshold of automation transformation for small and medium-sized enterprises from the dimensions of cost and applicability. HITBOT has got over 50 patents and utilized them to optimized the machine performance and user experience, such as the easiest way of programming by graphic teaching, APP teaching, drag teaching.

HITBOT has a production facility of over 10,000 square meters, achieving an annual output of 20,000 pieces. Starting overseas business in 2018, HITBOT cobots and grippers have all been certificated with CE and FC, and sold to over 20 countries such as the US, CA, JP, SG, UK, DE, and etc.

In the future, HITBOT will continue dedicating efforts in cobot innovation to promote realizing the transformation of Industry4.0 for small and medium-sized enterprises.

FAQ

1. Who are we?

We are based in Guangdong, China, start from 2015, sell to Eastern Asia(60.00%), Domestic Market(20.00%), North America(10.00%), Western Europe(10.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Robot arm,Robot gripper,Robot manipulator,Linear actuator,Industrial robot

4. Why should you buy from us not from other suppliers?

Established in 2015, HITBOT is 5-year experienced collaborative robot manufacturer, mainly specializing in designing and producing light-weight table-top collaborative robot and electric robot grippers.

5. What services can we provide?

Accepted Delivery Terms: FOB;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,PayPal;

Language Spoken:English,Chinese

VIEW MORE

YOU MAY LIKE