Low Cost Linear Motion Slides Linear Slides and Ball Screw Electric Linear Slides

- $100.00 / 1 - 9 pieces

$90.00 / >=10 pieces - 1 piece

- Jinan Levo Bearing Import & Export Co., Ltd.

- Shandong, China

- Ms Hongxia Liu

PRODUCT DETAIL

| width: | 178mm | Video external inspection: | if |

| Supply capacity: | 1000 sets per month | color: | Nickel White |

| Ball screw diameter and lead: | 20mm, 05mm | Motor brand and power: | Delta 75 750W |

| feature: | High precision and low noise | brand: | boo boo |

| strength: | 750w | place of origin; place of origin: | Shandong China |

| high: | 97mm | Applicable industries: | Manufacturing plants, machinery repair shops, other |

| Dimensions (L*W*H): | 767*178*97MM | Marketing Type: | New Products 2022 |

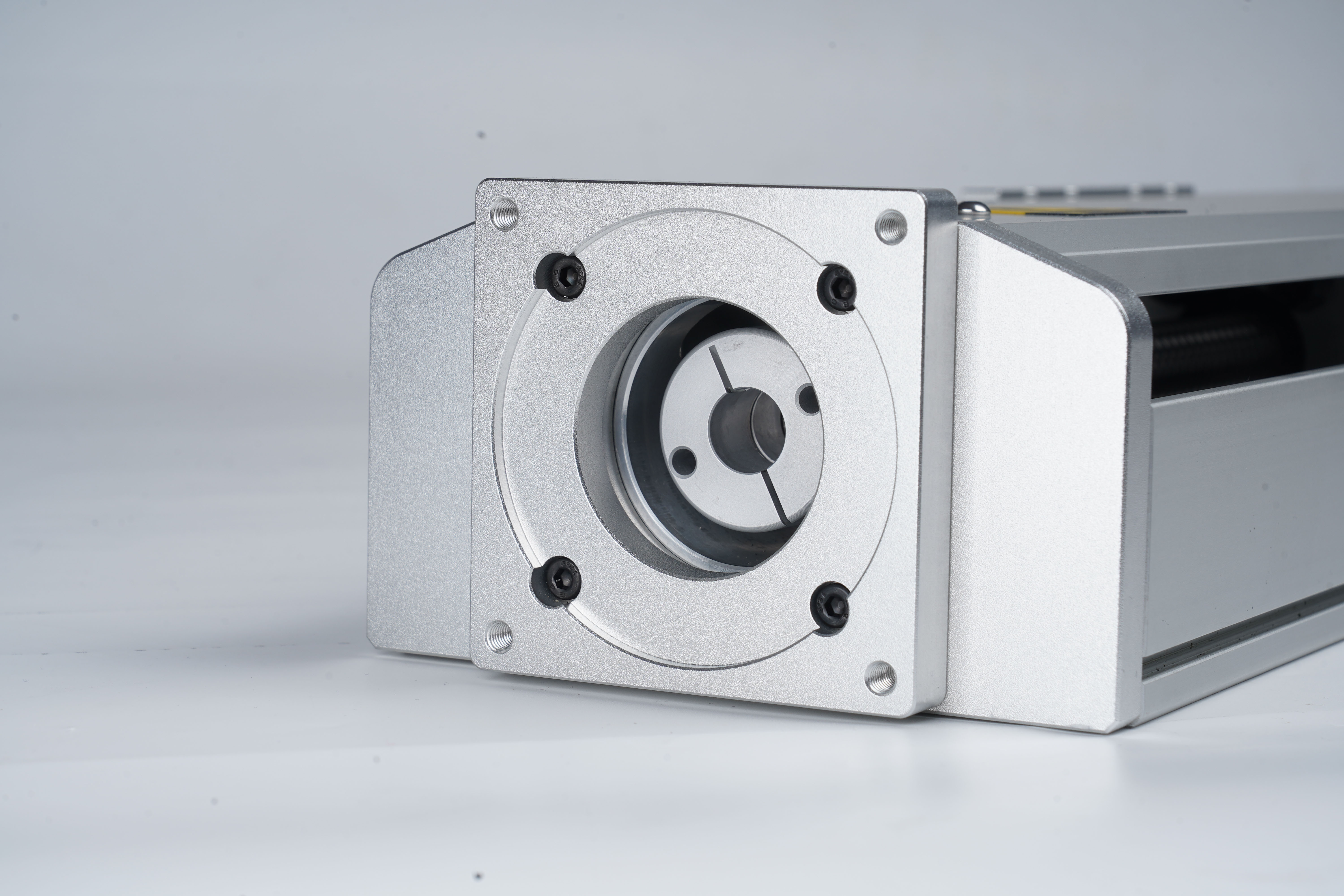

| application: | move/lift/cut/drill | Motor position: | Direct motor connection |

| Core Components Warranty: | 1 year | length: | 767mm |

| Core components: | bearing | Production capacity: | 98% |

| Health status: | new | port: | Qingdao |

| payment terms: | Western Union, T/T, MoneyGram, Payapl | Voltage: | 220v |

| Weight (kg): | 24.75 | Packaging Preview: | |

| Packaging Details: | Single color box + carton packaging | Mechanical test report: | Not available |

| Valid itinerary: | 500mm | Showroom location: | not any |

| Warranty: | 1 year | product name: | Linear module |

| custom made: | Brake or not / home position sensor or not |

Product display:

Product advantages

Material

The metal table, frame and cover plate of the linear module are all made of high-quality aluminum plate, which has the advantages of sturdiness, stability and load-bearing. In addition, the installation table of the module adopts the grinding process, and the cooperation between the transmission parts and the table is very good, so that the operation of the module is extremely stable.

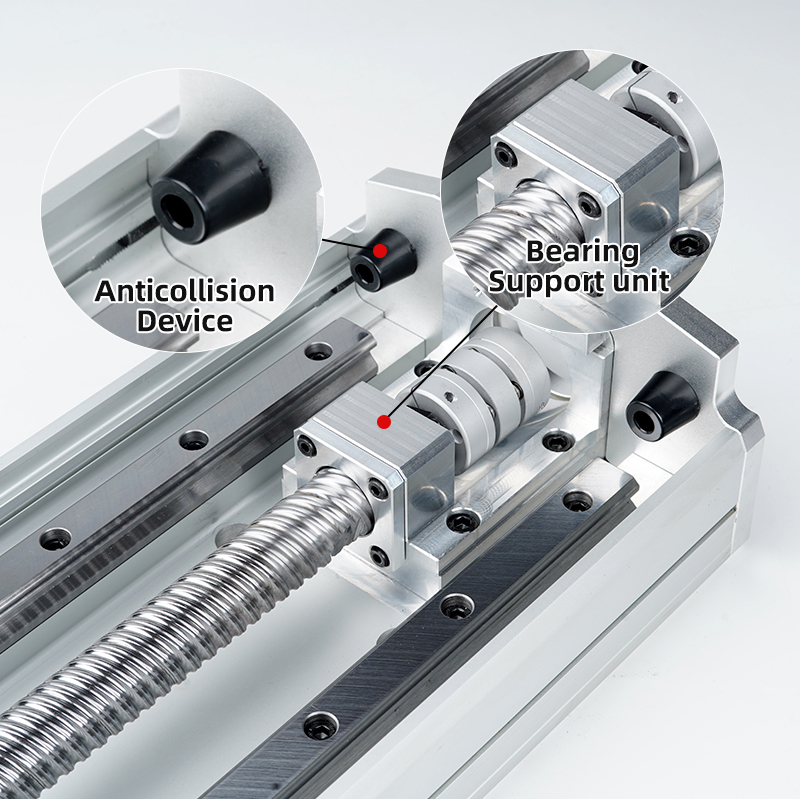

Transmission parts

The transmission part adopts high-quality and high-precision linear guides and ball screws, so that the linear module has low noise and good stability. In addition, we use a high-precision support unit on the fixed end of the drive ball screw, which will not shake under heavy load, ensuring its perfect running effect.

Specification

Combination application

Sample #1:

Three-axis drive

OEM order

Equipped with servo motor

This is a fully automatic packaging air conditioner production line customized for air conditioner manufacturers. The whole process realizes automation of grabbing, placing and packaging to improve production efficiency.

Sample #3:

This is a pneumatic automatic gripper arm, linear slide and actuator system

VIEW MORE