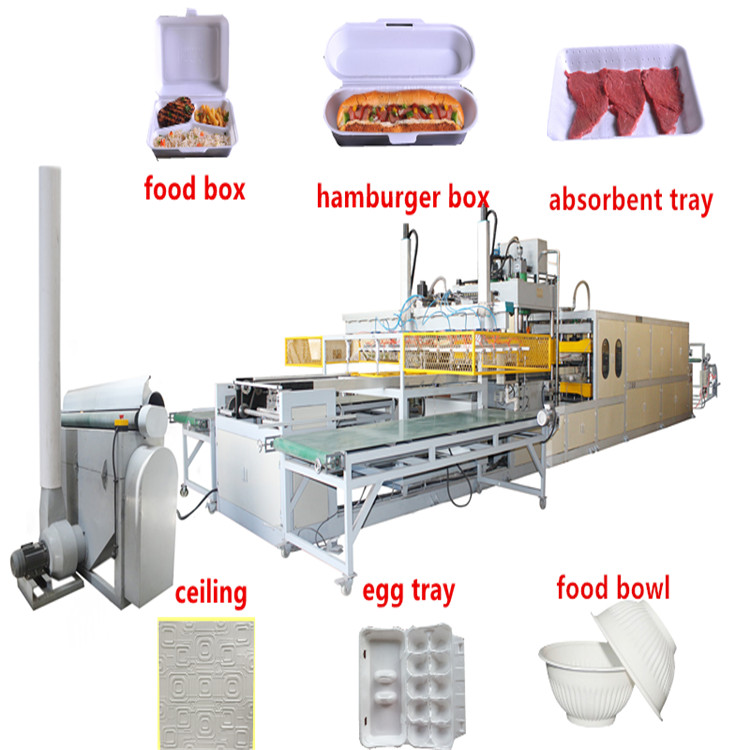

Low price foam food box plate making machine/egg tray machine

- $33000.00 /set

- 1 set

- Longkou Haiyuan Plastic Machinery Co., Ltd.

- Shandong, China

- Ms Elle Shung

| Air consumption(L/min): | 1 l/min | Dimensions (L*W*H): | 19000*6000*3000 |

| raw material: | GPPS, HIPS, talcum powder, butane gas | Mechanical test report: | if |

| capacity: | About 500,000 egg trays | After-sales service provided: | Video technical support, free spare parts, on-site installation, commissioning and training, on-site maintenance and repair services, online support |

| Water consumption (l/min): | 1 l/min | Forming length (mm): | 1400 mm |

| usage: | Widely used in food packaging, precision instrument packaging | manufactures: | foam egg tray, box, container, box, plate, tray, box |

| Type of machine: | Plastic thermoforming machine | Sheet thickness (mm): | 1 - 5mm |

| Applicable industries: | manufacturing plant, food and beverage factory, restaurant, home use, food store, food and beverage store, advertising agency | Health status: | new |

| Packaging Details: | 1. Foam food box plate-making machine/PE film low-cost packaging egg tray machine 2. Qingdao port low-cost foam food box plate-making machine/egg tray machine 3. Foam food box plate-making machine/egg tray machine low-cost total weight about 30 tons 4 .Low price foam food box plate making machine/egg tray machine needs three 40HQ | Forming width (mm): | 1100mm |

| Local service location: | Egypt, Vietnam, Algeria, Nigeria | Certification: | ce |

| Core components: | PLC, motor | Maximum molding height (mm): | 100mm |

| Warranty: | 1 year | Machine name: | foam egg tray machine |

| Production speed (cycle/min): | 900 | port: | Qingdao |

| Power(kW): | 180 | experience: | over 20 years |

| Core component warranty: | 1 year | Video shipment inspection: | if |

| Weight (ton): | 10 tons | Voltage: | 380v |

| Product Category: | snack box | Marketing Type: | 2019 Hot Products |

| Main selling points: | competitive price | brand: | Haiyuan |

| After warranty service: | Video technical support, online support, spare parts, on-site maintenance and repair services | Origin: | China |

| Heating power (kW): | 55 kW | Air pressure (MPa): | 10MPa |

| Controller: | PLC+touch screen | Automatic level: | fully automatic |

| Showroom location: | Egypt, Vietnam, Nigeria | Supply capacity: | 50 foam food box egg tray making machines per year |

| payment terms: | L/C, Western Union, T/T | Plastic Type: | hip, PS, EPS |

| Package preview: | Plastic Type: | polystyrene | |

| Processing type: | Plastic thermoforming machine |

Low price foam food box plate making machine/egg tray machine

Longkou Haiyuan Plastic Machinery Co., Ltd. specializes in ps foam thermoforming machinery. include:

1. PS foam thermocol tray/plate/dish making machine

2. PS foam lunch box machine

3.PS foaming bowl making machine

4. Takeaway food container production line manufacturing machine

5. PS foam suction tray/dish/dish machine

6. PS foam egg tray/wine tray making machine

7.PS foam burger box/pizza box making machine

8. PS foam ceiling machine

9. PS foam sheet extrusion line

Foam food box plate making machine/egg tray machine automatic production line includes 3 parts:

1. PS foam sheet extrusion line

2. Fully automatic vacuum forming machine

3 Shredder recycling machine

Foam food box plate making machine/egg tray machine semi-automatic production line includes 4 parts:

1.PS foam sheet extrusion line

2. Semi-automatic vacuum forming machine

3. Cutting machine

4. Crushing recycling machine

The difference between a semi-automatic production line and a fully automatic production line: only the difference of the blister machine:

The automatic vacuum forming machine is heating, forming, cutting and stacking at the same time, and the semi-automatic vacuum forming machine is heating and forming at the same time, which requires a cutting machine to complete the production.

1.PS foam sheet extrusion line

There are two hot-selling models of extruders in our factory, they are: HY-75/90 and HY-105/120

There are two hot-selling models of extruders in our factory, they are: HY-75/90 and HY-105/120

Technical process of PS foam sheet extrusion production line:

1. Material mixing --- 2. Material entering extruder 1 (foaming agent) --- 3. Net exchanger (filtering) --- 4. Material entering extruder 2 --- 5. Sheet from Die extrusion-- --6. Cooling and shaping---- 7. Traction -----8. Winding----9. Finished product----10. Package

The raw material is ordinary polystyrene granules. During the extrusion process, the foaming agent is injected under high pressure. After extrusion, foam cooling, shaping, and traction, it is wound into a finished PS foam sheet coil, which is passed through a vacuum forming system. Finally, the finished PS foam sheet can be made into various packaging containers. Such as ps foam thermocol plates, trays, dishes, boxes, containers, bowls, absorbent trays, dishes, plates, foam ceilings, etc.

scope

| parameter | unit | HY-75/90 | HY-105/120 |

| capacity | kg/h | 80-100 | 200-240 |

| Sheet thickness | mm | 1-4 | |

| paper width | mm | 640-1080 | |

| Foam rate | 10-22 | ||

| cooling method | Air-cooled water-cooled | ||

| cutting method | single | ||

| butane gas pressure | MPa | 0.9-1.2 | |

| Installed power | kilowatt | 150 | 180 |

| installation size | rice | 24*6*3 | 30*6*3 |

| power supply | 380v50hz 220v60hz | ||

2. Fully automatic vacuum forming machine

Foam food box plate making machine/egg tray machine low price integrated forming, cutting, stacking at the same time, foam products can come out automatically, it is vacuum forming as well as press forming and synthetic forming, it can be used for processing various plastic sheets. It uses PLC controller and touch screen to control the working procedure. It is easy to operate and has a high degree of automation.

The low price foam food box plate making machine/egg tray machine can produce containers of different shapes by changing the mould.

Such as: ps foam thermocol trays, plates, plates, boxes, bowls, foam absorbent trays, dishes, dishes, ps foam ceilings, egg trays, wine trays, etc.

scope:

| scope | unit | HY-1100 | HY-1250 | HY-1400 |

| Forming area | mm | 1100*1100 | 1100*1250 | 1100*1400 |

| cut height | mm | 160 | ||

| Productivity | dead/dead | 3-6 | ||

| installation size | rice | 19*6*3 | 21*6*3 | 24*6*3 |

| Installed power | kilowatt | 160 | 180 | 200 |

| power supply | 380V50HZ 220V60HZ | |||

3. Recycling machine

The recycling machine is mainly used to recycle ps expanded polystyrene products. It is an ideal equipment for waste recycling. The equipment has a compact structure and is easy to operate. The waste can be directly granulated without being crushed. At present, it is an ideal energy-saving device for recycling materials and reducing waste. equipment.

scope:

| scope | HY-125 |

| Screw diameter | 125mm |

| Installed power | 30 kW |

| aspect | 8*3*2mm |

| weight | 1.5 tons |

| power supply | 380v50hz 220v60hz |

4. Machine products:

PS foam thermocol plates, trays, plates, containers, boxes, bowls, ps absorbent trays, egg trays, wine trays, foam ceilings, etc.

Foam food box plate making machine/egg tray machine with low price and standard packaging for export:

Low Price Foam Food Box Plate Making Machine/Egg Tray Machine Related Brands: