Millet Legumes Gravity Separator Machine For Sale

- $8100.00 /set

- 1 set

- Kaifeng Hyde Machinery Co., Ltd.

- Henan, China

- Ms Nissi Yang

| Supply Ability: | 10 Sets per Month; | Certification: | ISO9001:2008 , CE; |

| Local Service Location: | Egypt,France,Viet Nam,Philippines,Brazil,Peru,Indonesia,Pakistan,India,Thailand,Malaysia,Kenya,Argentina,South Korea,Chile,UAE,Colombia,Algeria,Sri Lanka,Romania,Bangladesh,South Africa,Kazakhstan,Nigeria,Uzbekistan; | After Warranty Service: | Video technical support,Spare parts; |

| Place of Origin: | Henan, China; | Machinery Test Report: | Provided; |

| Core Components: | Motor; | Warranty of core components: | 1 Year; |

| Sieve Size(mm): | 2.48 squire meters; | Showroom Location: | Australia,Nigeria; |

| Model: | 5XZ-3; | Marketing Type: | Hot Product 2019; |

| Power (kW): | 7.45; | Use: | Grain & Beans Fine Sorting; |

| Packaging Detail: | Export standard seaworthy plywood case for LCL shipment. Plastic wrapped or loose package for container load of 5X Super Fine Seed Cleaner grain cleaning machine.; | After-sales Service Provided: | Field installation, commissioning and training; |

| Type: | Gravity Table; | Production Capacity (kg/h): | 1000 - 3000; |

| Dimension(L*W*H): | 2750*1550*2040mm; | Warranty: | 12months,1 Year; |

| Keywords: | Grain Processing Equipment; | Main market: | America Africa; |

| Product name: | 5XZ-3 Gravity Separator Machine; | Applicable Industries: | Farms; |

| Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; | Selection Rate: | ≥98.5%; |

| Brand Name: | Hyde; | OEM Service: | Grain Cleaning Screen Customized; |

| Capacity: | 3 T/H; | Impurity Removing Efficiency: | ≥99%; |

| Port: | Qingdao/Tianjin/Shanghai; | Key Selling Points: | Long Service Life; |

| Video outgoing-inspection: | Provided; | Color: | White and Blue; |

| Condition: | New; | Package Preview: | ; |

5XZ Gravity Table

Product Application

1) Function: fine cleaning, sorting, separating to remove bad, immature, insect damaged, moldy and germinated seeds, impurities, and admixtures such as same-size stones but with different specific weight.

2) Application: granular grains and seeds.

3) Capacity: 3t/h, 5t/h, 10t/h, 15~20t/h (wheat).

Working Principle.

Seeds and grains can be separated and graded by the suspension and friction characteristics.

Seeds flow over the inclined vibrating screen covered rectangular deck, in which pressurized air is forced through causing the material to be suspended and stratify according to its specific weight. The heavy particles float uphill while the light particles travel downhill.

Rectangular deck makes the particles travel a longer distance, ensuring the cleaner separation of light and heavy particles and the lowest percentage of middlings, improving the quality of the end product.

Feature.

Optimal effects rely on the precise adjustment of feed rate, screen deck inclination (lengthwise and sidewise), vibration speed and air volume.

Structural features:

1) Heavy duty and robust steel structural frame to absorb the vibrations.

2) Fans are dynamically balanced with individual adjustable controller for each fan for precise control of air flow and easy maintenance.

3) Cellular vertical air distribution device mounted under the deck make the air lifting evenly.

4) Square woven mesh screen made of steel wire with no bottom fabric ensures air passing through no dead band.

5) Variable feed speed, deck inclination, vibration speed and air volume by individual control units.

6) Safe guards to all moving parts ensure the safe operation.

7) Environmentally friendly with screen dedusting cover, low noise.

Special features:

1) Built-in fans are air-conditioner fans with lower noise, higher pressure and larger amount of wind.

2) Larger motor for heavy seed.

3) Self-lubrication system can be added.

4) Stainless steel available for edible products.

Model | 5XZ-3 | 5XZ-5 | 5XZ-10 | New Type 5XZ-10 | 5XZ-20 |

Rated Capacity (T/H) | 3 | 5 | 10 | 10 | 15-20 |

Dimension(L*W*H) mm | 2750*1550*2050 | 3840*2110*2040 | 2750*1550*2050 | 2750*1550*2050 | 2750*1550*2050 |

Total Weight (Kg) | 1000 | 1400 | 2300 | 2200 | 3500 |

Total Power (kW) | 7.45 | 9.55 | 19.9 | 17.57 | 30.3 |

Amplitude (mm) | 7 | 7 | 7 | 7 | 7 |

Dip Angle (°) | 30 | 30 | 30 | 30 | 30 |

Frequency (Hz) | 300-800 | 300-800 | 300-800 | 300-800 | 300-800 |

Screen Area (㎡) | 2.48 | 3.66 | 5.36 | 5.40 | 8.42 |

Selection Rate (%) | ≥98.5% | ≥98.5% | ≥98.5% | ≥98.5% | ≥98.5% |

Impurity Removal Rate (Light) | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% |

Impurity Removal Rate (Heavy) | ≥95% | ≥95% | ≥95% | ≥95% | ≥95% |

Machine Parts

Name: Working Table

T The nest important part of the Gravity Separator is the sieve deck because it is the main separating surface. It consists of a carefully constructed wooden frame to counteract vibration problems with a steeless screen or cloth overcover which is the surface on which the separation takes place.

Main Features

Name: Finger Plate

On the open end of the deck are mounted two cutting fingers which are adjustable to channel different fractions of the finished product according to their value. On the heavy side of the deck towards the feed end is the rock trap which is used to bleed a heavy trash product from the machine to avoid contamination of good heavy product

Machine Parts

Name: Adjustable hadle and panel for air blower

Air regulation is one of the most important adjustments to

be made on a gravity separator. The most common mistake in air regulation is the use of too much air. Separation is not made by "blowing" the light material from the heavy but by using a controlled air flow to create the stratified layers which are then separated by the vibrating action of the deck

Main Features

Name: Material Outlet

It is consisted of three outlet, which is heavy Discharge, Middle discharge and Light discharge to have a good effect.

Contact US

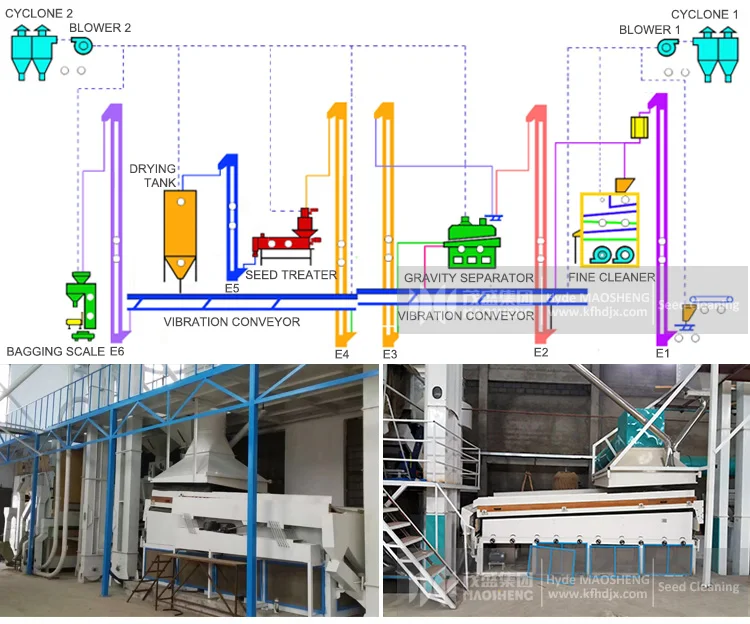

Application of 5XZ Gravity Table

5XZ series gravity separator is widely used to remove impurities, admixture, insect damage and immature kernels from cereal grains such as wheat, barley, oilseed rape, peas, beans, cocoa beans, hazelnuts, linseed.

5X Fine Seed Cleaner

97.8% Response Rate

5XW Indented Cylinder

93.7% Response Rate

Destoner

99.8% Response Rate

1) 40 YEARS manufacturing experience since 1976.

2) CHINA TOP 10 Grain Processing Machinery Manufacturing Company.

3) Member of 13 China national standards DRAFTER in grain processing industry.

4) 75 PATENTED technologies and products.

5) 600,000 square meter production area.

6) Over 100 experienced engineers, research staff and technicians.

7) State-of-the-art facilities. Advanced imported CNC machines for function parts.

8) Full range of service, from single machine to turnkey systems in grain and flour industry.

9) Machinery and equipment quality tested by domestic and global market, rich installation and trouble-shooting experience.

State Leader Visit

With 40 years' growth, Maosheng Group company has become one of CHINA TOP 10 Grain Processing Machinery Manufacturer. In addition, Maosheng is the host of CHINA National Grain Processing Technology Research Center.

Kaifeng Hyde Machinery, separated in 2000 as a branch company, mainly manufactures a full range of advanced grain and seed processing machines.

National Patents

Member of 13 China national standards DRAFTER in grain industry. 79 patents including 4 inventions (till 2018).

Pre-sales Service.

1.. Technical Consulting Service

Our wide product range enables us to provide flexible, efficient and reliable equipment and complete solutions for customers according to different requests and budgets.

2. Company and Production Line Visit

Before placing orders, customers are warmly welcome to visit Hyde and our facility.

In-sales Service.

1. Reliable delivery time.

2. Strict quality control by in-production 100% check and test.

3. User manual and spare parts provided for free.

After-sales Service.

1. Fast technical guidance for construction, installation and commissioning.

2. Necessary training for daily maintenance on site.

3. 12 months warranty.

4. Lifelong regular technical service.

5. Timely solutions to problems..

FAQ

Q: What do you need to know for fast communication and quotation?

A: It would be highly appreciated if you can provide details of your processing material specs, capacity and efficiency request, screen specification, motor power supply voltage and special brand needed, and other working conditions.

Q: Can you make the machines as per our special requirement?

A: Yes, OEM/ODM service available.

Q: What about the lead time?

A: 10~30 workdays, depending on the type of machine and parts availability.

Q: What is your payment terms?

A: T/T, L/C, Western Union, Cash accepted.

30% deposit with purchase order, 70% balance paid before shipment.

Q: How can you guarantee the quality?

A: Quality control by incoming material inspection, 100% in-production check and random check after packaging.

Spare parts and technical solutions provided timely for machine failure.

Q: How do we visit your company?

A: Hyde Machinery is located in Kaifeng City, Henan Province, China.1 hour drive from nearest Zhengzhou airpor