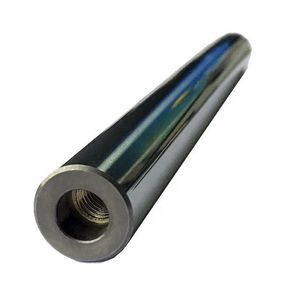

Multi-purpose tool shank carbide internal thread locking anti-vibration tool shank

- $35.00 /piece

- 1 piece

- Zigong Dingli Alloy Material Co., Ltd.

- Sichuan, China

- Ms Hua Li

| surface: | polishing | Supply capacity: | 5000 pieces per month |

| grade: | YG15 | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,VISA |

| Packaging Preview: | ID: | M3-M16 | |

| diameter: | 6~32mm | Certification: | GS |

| port: | Chongqing, Shanghai, Guangdong, Qingdao, Shenzhen, Hong Kong, Ningbo, etc. | Material: | Tungsten Carbide |

| place of origin; place of origin: | Sichuan, China | type: | boring bar |

| TRS: | 3500~4500 N/mm2 | Outer diameter: | 6~32mm |

| length: | 100~400mm | hardness: | Human Resources Administration 87.5 |

| Packaging Details: | Plastic bags or plastic boxes in wooden boxes/cartons/tin boxes, etc. | brand: | Dingli |

| density: | 13.95~14.5 g/cm3 | product name: | Carbide boring bars |

Multipurpose tool holder

>>Ultra-Cemented Carbide Rods are manufactured with a unique cemented carbide formulation for toughness and durability to achieve vibration resistance, high hardness and high rigidity for long and deep hole machining (up to 12D)

>>All specifications have internal cooling holes, which are beneficial to deep hole processing and have good performance.

The processing depth of the straight shank structure can be adjusted according to the requirements

>>Multi-purpose toolholder (with special thread link adapter for turning and milling, ST boring bar) increases insert life and improves productivity.

>>Tool rod thread is made by grinding process, the thread is more stable and durable, not easy to be damaged or collapsed.

- Carbide grade:

Zigong Dingli Alloy Co., Ltd. is located in the new industrial parkZigong, Sichuan, China's famous cemented carbide production base. ThisfactoryMainly engaged in the production and development of various cemented carbide products, such asRod tubes, carbide boring bars and flat bars.In China, our goal is to become a manufacturing center for extruded bars, carbide boring bars, standard tools, non-standard tools and hard machining tools, and to establish a good and healthy corporate image in the industry.

The main production equipment:

Currently, companies can. In general, our products can be used to make molds, electronics, automobile engines and accessories, military equipment, petroleum machinery, machinery manufacturing, etc. We have stable customers such asUnited States, Russia, Indonesia, South Korea, Japan, Australiaand many more.

Testing Machine:

Our company was established in July 2011. The company's product quality and reputation have reached the domestic middle and upper level, second only to several most competitive cemented carbide enterprises. We continue to improve technology and introduce advanced equipment, which greatly improves the professionalism and production scale.

Production flow chart:

Package

1> Put the goods packed in plastic bags or plastic boxes into wooden boxes/cartons/iron boxes, etc.

2>Other packaging will be accepted according to your needs.

FAQ

Q1: How long is your delivery time?

A1: It depends on the specific situation. However, it may take 10 to 15 days on average.

Q2: Do you provide samples?

A2: Yes, we provide samples. However, buyers need to pay for shipping. Also, whether the sample is free or not depends on the quantity you purchase.

Q3: How do you package the product?

A3: Generally, we use wooden boxes, plastic boxes or carton boxes. We also put some soft material inside to prevent possible damage to the product.

Q4: How much prepayment do I need to pay?

A4: If the product you purchased is in stock, you need to pay in full; if the product is out of stock, you need to pay about 50% of the full payment, then we will start the production process. However, you still need to pay the rest of the cost before we deliver the product.

Q5: What payment methods do you accept?

A5: In addition to the payment methods shown above, you can also discuss with us which method you would like to pay.

Other Products

-

2023 new solid carbide drill pipe/alloy rod/tungsten carbide rod$0.68 - $0.84 / piece

2023 new solid carbide drill pipe/alloy rod/tungsten carbide rod$0.68 - $0.84 / piece -

Block gauge set 32PCS 38PCS 47PCS 83PCS 87PCS 103PCS 112PCS 122PCS, individual block gauge$5.00 / piece

Block gauge set 32PCS 38PCS 47PCS 83PCS 87PCS 103PCS 112PCS 122PCS, individual block gauge$5.00 / piece -

140mm long inverted tapered special serdi carbide guide, carbide guide drill pipe$14.80 - $26.00 / piece

140mm long inverted tapered special serdi carbide guide, carbide guide drill pipe$14.80 - $26.00 / piece -

High precision inverted cone 190mm long serdi carbide guide, carbide pilot drill pipe$23.00 / piece

High precision inverted cone 190mm long serdi carbide guide, carbide pilot drill pipe$23.00 / piece -

unground tungsten cemented carbide single straight hole tube$0.50 / piece

unground tungsten cemented carbide single straight hole tube$0.50 / piece