NETZSCH shaft seals for progressive cavity pumps or progressive cavity pump shaft seals

- $10.00 /piece

- 1 piece

- Guangdong Standard Fluid Systems Co., Ltd.

- Guangdong, China

- Ms June Zhang

| port: | Foshan, China | Pump Parts and Accessories: | Wheel cover |

| Packaging Details: | Single product carton packaging Multiple product wooden box packaging, no more than 30 kg per box | Supply capacity: | 5000 pieces per month |

| model: | NM021 | Package preview: | |

| place of origin; place of origin: | Guangdong, China | payment terms: | Western Union, T/T |

| brand: | Netzsch | Standard or non-standard: | standard |

Mg1/mg12/mg13

Brand: STD seals

Application: screw pump, chemical pump, water pump, impurity pump

Applicable industries: smelting, papermaking, oil refining, fine chemicals, sewage treatment, etc.

Features:

Sealing surface: graphite, hard alloy, SIC, etc.

Auxiliary seal: nitrile, ethylene propylene, fluorine rubber, etc.

Metal composition: 304, 316L, etc.

Structural features: single end face, unbalanced, arbitrary rotation, rubber bellows

Working parameter version:

Specifications: 10-100mm

Pressure: ≤1mpa

Temperature: -20°C–150°C

Linear speed: ≤10m/s

Applicable medium: sewage, oil and weak corrosive medium

notes:

Mechanical seal precision parts, during the installation process, do not smash the sealing element!

Non-assembled mechanical seal

1. Assemble the static part of the mechanical seal into the pump chamber gland.

2. When the mechanical seal adopts a V-shaped ring structure, special attention should be paid to the V-shaped opening must face the pressure direction of the medium (or sealing fluid) during installation.

3. The mechanical seal element set on the pump shaft (the V-shaped hole must also face the direction of pressure) determines the position of the spring seat according to the model specification and adjusts it as required to make the spring pressure meet the design requirements. So as to ensure the normal working pressure of the sealing surface. Tighten the screws evenly.

4. Install the mechanical seal with one-way rotation (that is, ring or hook spring transmission), especially pay attention to the rotation of the spring, and its rotation direction should be consistent with the rotation direction of the shaft to make the spring tighter. From the mechanical seal to the end of the static ring, judge the rotation direction of the shaft, clockwise is right, counterclockwise is left

2. Operation and Precautions

1. The mechanical seal is absolutely not allowed to run dry. Before the equipment is started, the pump must be completely emptied so that the medium is filled with the sealing chamber before the equipment can be opened.

2. The operation of the equipment should be carried out in strict accordance with the following procedures:

3. Before the equipment is running, the flushing water should be started, and after 5 minutes, the host should be started;

4. If the flushing water is not turned on, it will cause dry friction of the sealing surface, high temperature, burning of the sealing ring and coking of the sealing ring, resulting in complete failure of the seal. This phenomenon is more prominent in two-ended and faceted structures.

5. During the operation of the equipment, it should be checked frequently whether the flushing water is unblocked and whether the pressure meets the requirements; during the operation, the flushing water cannot be interrupted or stopped.

6. The best operation mode of the pump is to work continuously. If it must be shut down, the return sediment in the pipeline and pump chamber should be flushed. If you want to stop, you must first stop for 5 minutes and then flush the water can be turned off

instructions

Standard Factory Availability

1) ST D's factory has a variety of accessories, we offer quick turnaround to help reduce equipment downtime, you don't need to have a lot of inventory.

2) For spare parts, fast shipment is possible, ensuring that production is uninterrupted or reduced to a minimum of downtime. With good service and very competitive price, customers can earn time profit from cooperating with us.

very competitive price

As customers pay more and more attention to operation and maintenance costs, we need to prioritize the price and availability of spare parts when evaluating plant savings and efficiency.

Using their engineering knowledge and production capabilities, STD companies are able to produce spare parts of good quality and competitive prices (spare parts for NETZSCH, SPEEDEX, MONO, VISCOTEC, STD, etc.)

quality assurance

STD is a professional R & D and manufacturer of single screw pumps and spare parts. The product quality has been tested and recognized by customers in the professional market, and has won the recognition and praise of customers.

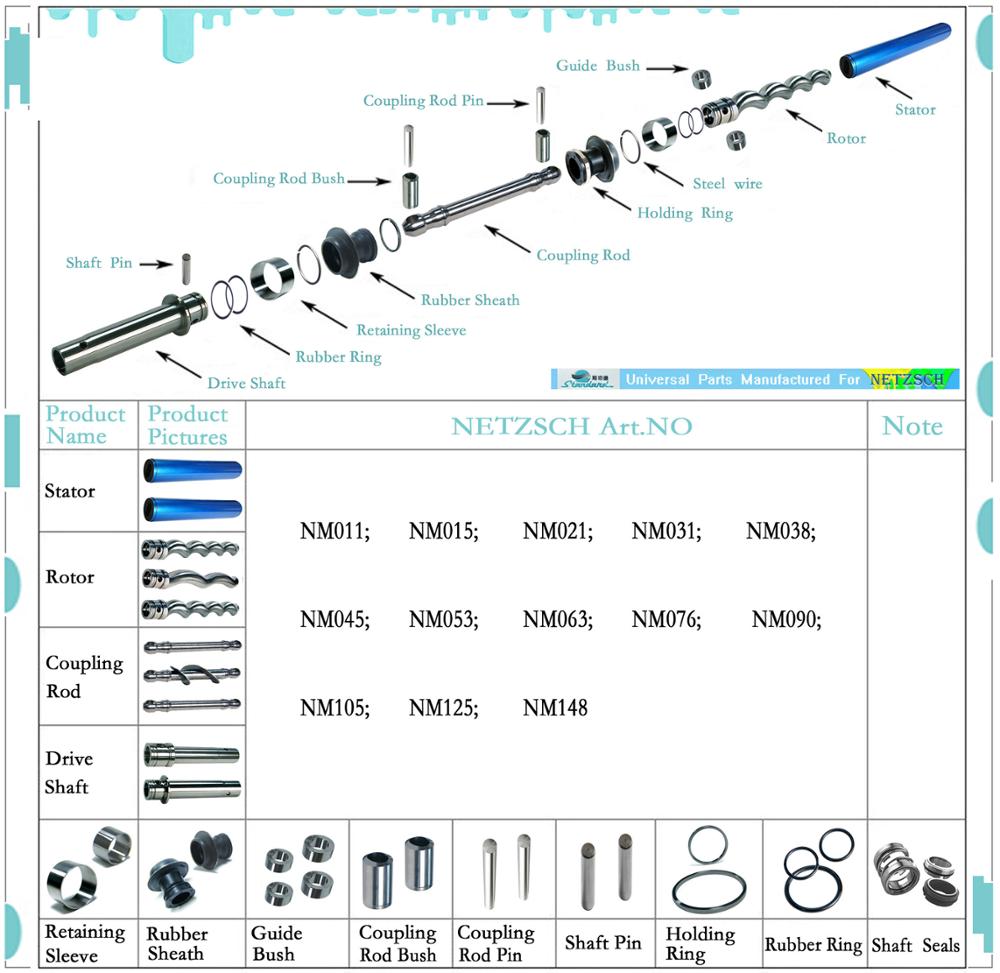

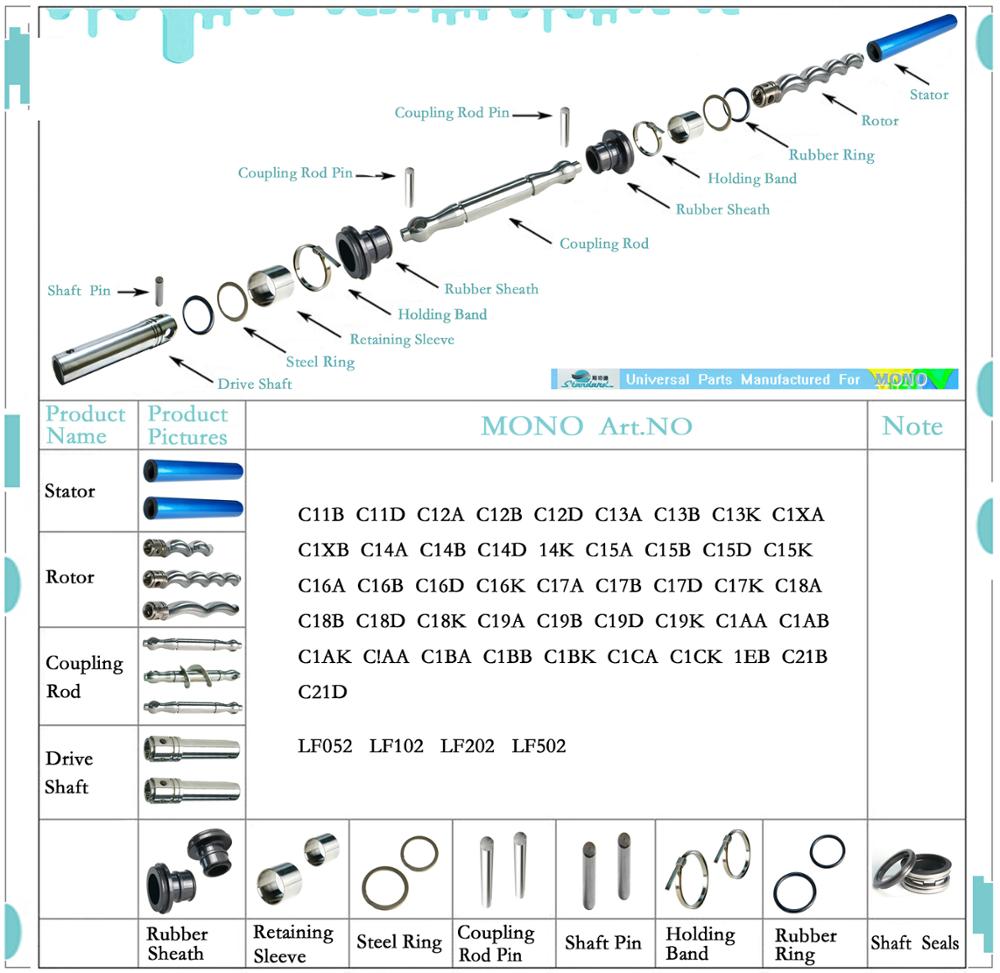

STD Common Parts Overview

STD has a solid reputation for the quality of its equipment and parts. In recent years it has been our mission to use our manufacturing and engineering expertise to expand our product offering to include a range of high quality STD common parts for many other brands of Progressive Cavity (PC) pumps.

We offer STD universal parts that can be used with other brands of single screw pumps in the following series. For others not listed, please contact STD

1) NETZSCH™ 2) SEEPEX™ 3) MONO™

International excellent brand screw pump accessories supply

STD uses its own expertise, manufacturing capabilities and channels to provide a full range of screw pump accessories for major global brands (Germany Netzsch, Seepex, Mono, etc.), these accessories are excellent in performance and durable, including: stators, rotors, drive shafts, Coupling, PIN, PIN or complete set of rotating parts, etc.

We can provide universal spare parts of NETZSCH brand

We can provide universal spare parts of SEEPEX brand

We can supply MONO brand general spare parts

certified

1) What products does STD offer?

STD provides global solutions for screw pumps, screw pump accessories, and fluid system products.

Product range overview of STD

Progressive cavity pumps for conveying and metering low to high viscosity media with or without solids

Macerators are used to macerate solid and fibrous components in media

Control systems for monitoring, regulating and controlling processes

Services: consulting, commissioning, maintenance, NETZSCH,SEEPEX, withmononucleosisGeneral spare parts, repairs and various service contracts

2) Does STD offer custom pumps?

Yes, this is our specialty, we customize our modular systems with different designs and material combinations for each application. This means we develop the best technical and most economical solution for your needs.

3) Can STD spare parts be ordered online?

Yes, it is possible to order STD Progressive Cavity Pumps and spare parts online as well as general accessories for other brands (NETZSCH, SEEPEX.MONO). To order, please contact us.

4) How soon can my STD pump be delivered?

Typically, standard pumps are delivered within 4 to 6 weeks. In urgent cases, the delivery time may be between 2 and 5 days. Please contact us. Tel: 0086 -189 4242 4342

5) Packaging; Transportation

1) Standard export packing: We pack the pumps and accessories in wooden cases and put them in containers. Shipping by sea and air. .

2) The marking on the packing box is carried out according to the international standard

3) Please check the packaging and integrity of the goods when receiving the goods, and report to the carrier immediately if there is any damage.

4) If you have special packaging requirements, please inform us.

6) Product quality assurance

According to international standards, the whole pump is guaranteed for 1 year,

6 months warranty on spare parts

Buyer Note:

1) Can the screw pump run dry?

No, the conveying elements are always in contact with each other, which means that dry running must be avoided in progressive cavity pumps. STD dry running protection device provides reliable protection.

2) What temperature is suitable for using STD pump?

STD Progressive Cavity Pumps can be used in temperatures ranging from -20 °C to 150° C (-4 to 302° F).

Company Profile

Guangdong Star Fluid System Co., Ltd. is the largest professional manufacturer of screw pumps, screw valves, and exhaust system screw products in South China

Screw pumps, screw valves, and exhaust system screw products have advanced technology, perfect structure, various forms, complete specifications, and durability, and are widely used in sewage treatment, chemical industry, papermaking, food processing, pharmaceuticals, energy, environmental protection, 3D printing and other industries .

The company has a team of engineers with rich experience, mature technology, high quality and trustworthy design, manufacture, testing and after-sales service of screw pumps. Provide customers with high-quality products, excellent solutions and efficient services in the field of fluid systems.

While producing and developing screw pump products, it also provides global screw product general accessories (including German Netzsch, Seepex, Viscotec, British mono and other brand accessories) and maintenance customization services, and provides free technical consulting services and improved optimized designs. Our excellent processing ability, rich practical experience and mature technical advantages provide a stable guarantee for our products.

our service

1 Our company's screw pump series products have reasonable prices, high-quality services, and quality inspections. OEM is welcome.

2 We have a dedicated quality supervision department to ensure the quality of mass production.

3 If there is a quality problem with the product, we will deal with it as soon as possible, find out the reason, and take responsibility.

4 If you are interested in our products and company, please leave us a message or email us, we will reply you within 24 hours

Why choose us?

1 Factory direct sales, no intermediate links, competitive price

2 Our machines are all original machines imported from Europe, the quality of the products produced is stable, and no inferior equipment is used.

3 Make sure delivery on time, purchasing, we can provide the best service quality control, shipping, documents, etc.

4 We provide samples and OEM service.

5 We will reply your inquiry within 24 hours.

6 More than 20 years of experience in the industry, as well as a professional team, make our customers feel at ease in cooperating with us

7 Please contact us by email, we will send you more pictures for you to choose our products.

How to order STD screw pump?

1) Sample approval

2) Customers arrange 30% deposit after receiving our PI (Proforma Invoice),

3) We start the mass production and finish the production within the agreed delivery time

4) We send the shipping documents to the customer

5) The customer arranges the balance payment

6) We arrange the shipment and send the original documents or telex the goods

|

Address: No. 2 Hengfeng Road, Science and Technology Industrial Park, Nanhai District, Foshan City, Guangdong Province |  |

|

| Tel: 0086-18942424342 | |||

| WeChat:0086-18942424342 | |||

| WeChat: 0086-18942424342 | |||

| Contact: Ms. Zhang Jun | |||

| Showroom: https://screwpump.en.alibaba.com | |||

| www.screwpump.top | |||

More styles are available in our showroom!>>>>>www.screwpump.en.alibaba.com

Other Products

-

SEEPEX Coupling Bush for Screw Pump or Coupling Bush Progressive Hollow Pump$2.00 / piece

SEEPEX Coupling Bush for Screw Pump or Coupling Bush Progressive Hollow Pump$2.00 / piece -

NETZSCH Spare Parts Guide$2.00 / piece

NETZSCH Spare Parts Guide$2.00 / piece -

Screw pump eccentric screw pump rubber stator$45.00 / piece

Screw pump eccentric screw pump rubber stator$45.00 / piece -

MONO progressive cavity pump or progressive cavity pump rubber boots rubber sleeves and universal joint sleeves and boots$5.00 / piece

MONO progressive cavity pump or progressive cavity pump rubber boots rubber sleeves and universal joint sleeves and boots$5.00 / piece -

SEEPEX Spare Parts Retaining sleeve$1.00 / piece

SEEPEX Spare Parts Retaining sleeve$1.00 / piece