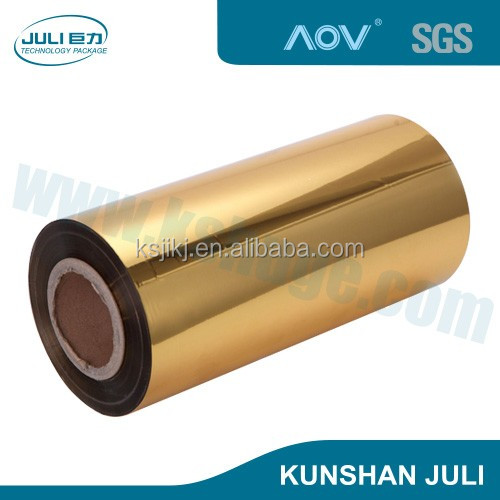

PET metallized thermal film/PET gold plastic thermal lamination film

- $2.77 / >=1000 kilograms

- 1000 kilograms

- Kunshan Juli Packaging Material Technology Co., Ltd.

- Jiangsu, China

- Mr Steven GU

| Supply capacity: | 1,000 metric tons of recycled metallized plastic film per month | brand: | cohesion |

| product name: | EVA pre-glue heat lamination micron BOPP film | Paper core: | 1" and 3" |

| model: | G-1208 | type: | art and design |

| length: | 150m to 4000m | usage: | Paper product lamination |

| Lamination temperature: | 85~105℃ | width: | 200mm--1800mm |

| port: | Shanghai, Ningbo, Shenzhen, etc. | thickness: | 15 to 40 microns |

| payment terms: | L/C, Western Union, T/T | raw material: | PET film & EVA glue |

| pack: | Cartons and pallets | Packaging Details: | Gold-plated metallized PET film: Laminated film for carton packaging; cartons will be packed on pallets; one 20ft container loads ten pallets. |

| type: | Magazine | Certificate: | ISO9001:2000, SGS, AOV |

| Origin: | Jiangsu, China | audience: | aldult |

EVA pre-glue heat lamination micron BOPP film

advantage:

1. Location: only 60 kilometers away from Shanghai.

2. Quality and service: good quality and competitive price and after-sales service.

3. Major: Nearly 12 years working experience in this field.

4. Product support: powerful production equipment and professional R&D team.

5. Certificates: ISO 9001, SGS, REACH, RoHS6, etc.

application:

Widely used for book covers, reviews and magazines, brochures, posters, food wrapping paper, boxes, cartons and more.

Item Specifications:

1. Glossy BOPP film: 15-28 microns

2. Matte BOPP film: 15-28 microns

3. PET film: 16 microns

or as needed

Width: 200mm---1800mm

Length: 150m-4000m

Paper core (inner diameter): 25.4mm (1''), 76mm (3")

Connectors: <2

Corona treatment surface: A (inside); B (outside); A/B (both sides);

Surface tension (corona treatment): > 38dyne

Application manual:

Composite temperature: 85~105℃

Composite pressure: 5~15Mpa

Composite speed: 8~40 m/min

Advantages of Thermally Laminated BOPP Films (Glossy and Matte):

1. Enhance the value of finished products with high clarity and ultra-gloss finish. Prevent the film from being compressed, blistered and peeled. Protection from harmful substances and waterproofing make the prints last longer.

2. A variety of papers and inks are available, even powdered paper is suitable for lamination. After corona treatment on the surface, it is suitable for spot UV and hot stamping.

3. There is no need for glue adjustment, glue application, drying and other processes, saving costs. No special technique is required for operation, and the film can be used in both dry and wet lamination machines.

4. Environmental protection and pollution-free working environment. Since no toxic gas or volatile substances are emitted, it is harmless to health and safe to use.

Detailed specifications:

| Specifications | |||||||||

| Specification | 18 glossy | 20 glossy | 25 glossy | 27 glossy | 18 Matt | 20 Matt | 25 matte | 27 Matt | |

| Thickness (microns) | according to | 12 | 12 | 15 | 15 | 12 | 12 | 15 | 15 |

| Evergreen | 6 | 8 | 10 | 12 | 6 | 8 | 10 | 12 | |

| all | 18 | 20 | 25 | 27 | 18 | 20 | 25 | 27 | |

| Width (mm) | 360;390;440;540;590;780;880;1080;1320;1400;1600;1800. Or according to customer requirements. | ||||||||

| Length (m) | 200-4000 | ||||||||

| Corona treated surface | Single-sided, double-sided, or according to customer requirements. | ||||||||

| Connector | less than 2 | ||||||||

| tensile strength | MD:2.4*106dyne/cmCD:5.3*106dyne/cm | ||||||||

| paper core | 25.4 mm (1')/76 mm (3') | ||||||||

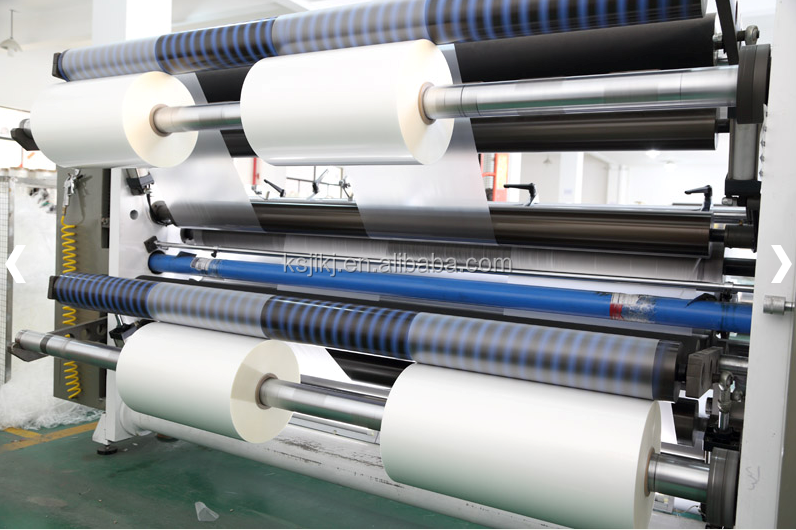

Production progress:

Due to the day and night operation of our three production lines, our output

It can reach 600 metric tons per month.

Our workshop:

Package:

exhibition: