PP PE HDPE LDPE LLDPE plastic granulator granulator granulator

- $2600.00 /set

- 1 set

- LAIZHOU TAIHE CHEMICAL MACHINE CO.,LTD

- Shandong, China

- Ms lynn leng

PRODUCT DETAIL

| Local service locations: | not any | Plastic processing: | HDPE, HDPE/PP, PE/PP, LLDPE, PP, LDPE |

| Showroom location: | not any | type: | Granulation production line |

| Voltage: | customer request | Dimensions (L*W*H): | depends on model |

| payment terms: | L/C, Western Union, T/T, MoneyGram | Marketing Type: | normal product |

| Key words: | Plastic granulator | After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services |

| Power (kW): | depends on model | Type of machine: | plastic granulator |

| Supply capacity: | 100 sets per quarter | Packaging Details: | Suitable conveying and protecting machines |

| capacity: | 100-500kg/hour | brand: | three dimensional |

| Function: | Plastic recycling granulator | Screw speed(rpm): | 1 - 57 rpm |

| weight: | 3000 kg | After-sales service provided: | Engineers available to repair machinery overseas, free spare parts, on-site installation, commissioning and training, on-site maintenance and repair services, online support, video technical support |

| Applicable industries: | Clothing store, building supply store, manufacturing plant, machinery repair shop, food and beverage factory, household, retail, food store, print shop, construction, energy and mining, food and beverage store, advertising agency | Core components: | engine |

| Screw design: | single | product name: | Plastic granulator |

| Output (kg/h): | 100 - 500 kg/h | Health status: | new |

| Video outbound inspection: | if | Warranty: | 1 year |

| port: | Qingdao | Certification: | EU CE certification |

| Package preview: | usage: | Plastic granulator | |

| Origin: | Shandong Province, China | Finished goods: | Plastic particles |

| application: | PP PE Plastic Granulator | Core component warranty: | 1 year |

| Material: | PP PE HDPE LDPE LLDPE | Mechanical test report: | if |

Product Description

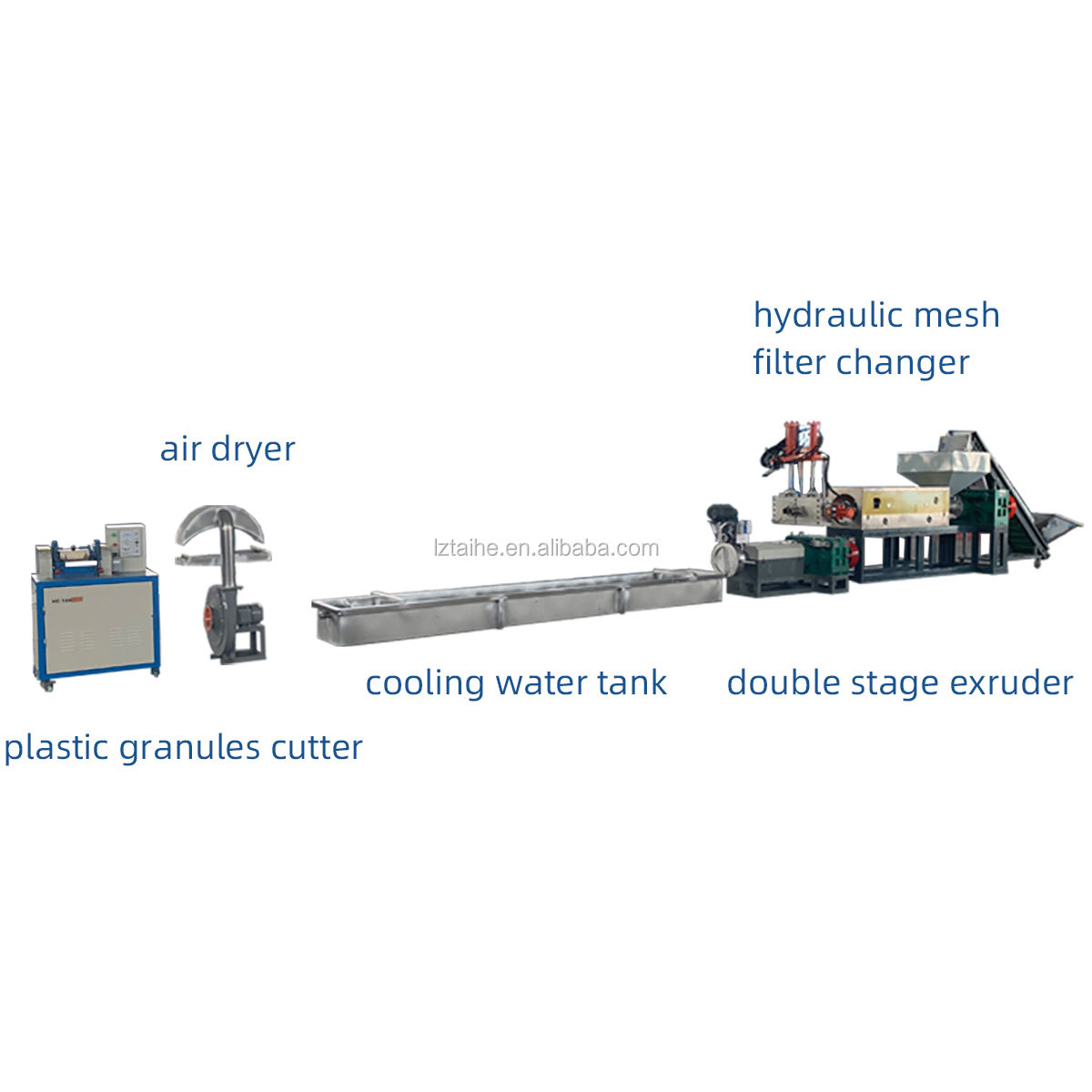

PP PE HDPE LDPE LLDPE plastic granulator granulator granulator

1. Application:

Applicable plastic materials: PP, HDPE, LDPE, LLDPE, etc. Material sources: PE bags, printed LDPE films, films (rolls, loose, bundles), agricultural film waste, polypropylene (non-woven fabrics), woven bags

2. Advantages of plastic granulator:

1. Significantly increase production

1. Significantly increase production

2. Continuous production

3. Flexible granulation method

4. The finished granules are well plasticized and have no pores

5. The main components (reducers, motors, frequency converters) are all well-known domestic brands, with guaranteed quality, long service life and good performance.

5. The main components (reducers, motors, frequency converters) are all well-known domestic brands, with guaranteed quality, long service life and good performance.

We also have more models, if you are interested in any products, please feel free to contact us.

Model | 125 | 135 | 150 | 180 | |||

capacity | 150 kg/h | 200 kg/h | 250 kg/h | 350 kg/h | |||

The diameter of the first stage screw extruder | 125mm | 135mm | 150mm | 178mm | |||

Second stage screw extruder diameter | 105mm | 125mm | 135mm | 150mm | |||

Motor power of the first stage extruder | 30 kW | 37 kW | 45 kW | 55 kW | |||

Second stage extruder motor power | 11 kW | 15 kW | 15 kW | 22 kW | |||

mesh filter changer | Electric Screen Filter Changer/Hydraulic Screen Filter Changer | ||||||

Comment | We have more models/support OEM | ||||||

detailed picture

Strong Magnetic Conveyor

Iron removal

Motorized Screen Filter Changer

Hydraulic Screen Filter Changer

first stage extruder

Second stage extruder

air dryer

remove water

Plastic pellet cutting machine

storage bin

more types

VIEW MORE

YOU MAY LIKE