Perforated aluminum sheet for custom design decoration

- $5.65 / 1 - 9 square meters

$3.33 / >=10 square meters - 1 square meter

- Hebei Weiyue Wire Mesh Products Co., Ltd.

- Hebei, China

- Mr Jia David

PRODUCT DETAIL

| normal width: | 1220mm, 1250mm, 1500mm, 1570mm | port: | Tianjin |

| model: | Wy056 | thickness: | 0.1-10mm |

| Warranty: | over 5 years | Origin: | Hebei china |

| type: | curtain wall | product name: | aluminum for walls |

| design style: | modern | Packaging Details: | plastic film+wooden box |

| Package preview: | After-sales service: | Online technical support, on-site installation, on-site training, on-site inspection, free spare parts, return and exchange | |

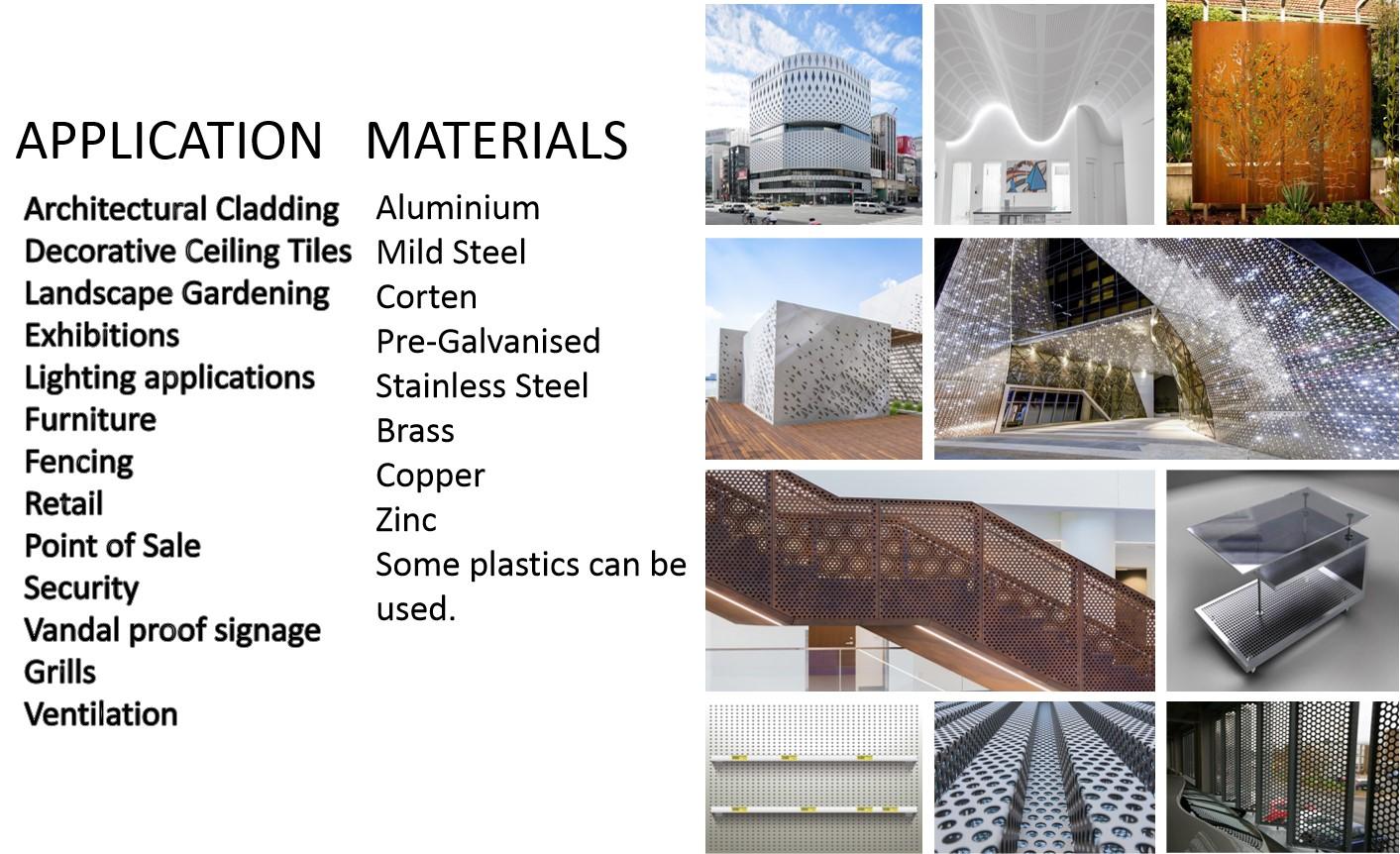

| application: | Building exterior walls, supermarkets | design: | Custom Aluminum Wall Panels |

| Project solution ability: | Graphic design, 3D model design, overall project solution, cross-category integration | payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

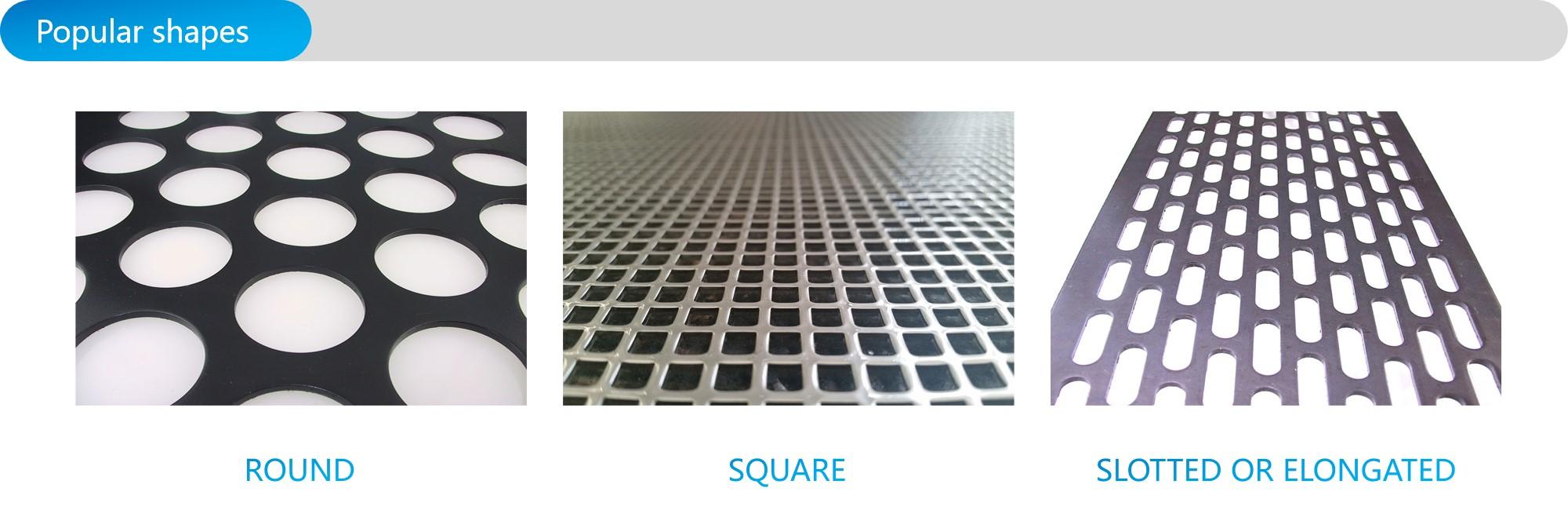

| Supply capacity: | 20000 square meters per week | Hole shape: | Square hole. Round |

| Material: | aluminum | length: | 10-30000mm |

| Hole size: | 0.1-20mm | Surface treatment: | powder coating |

| brand: | Weiyue |

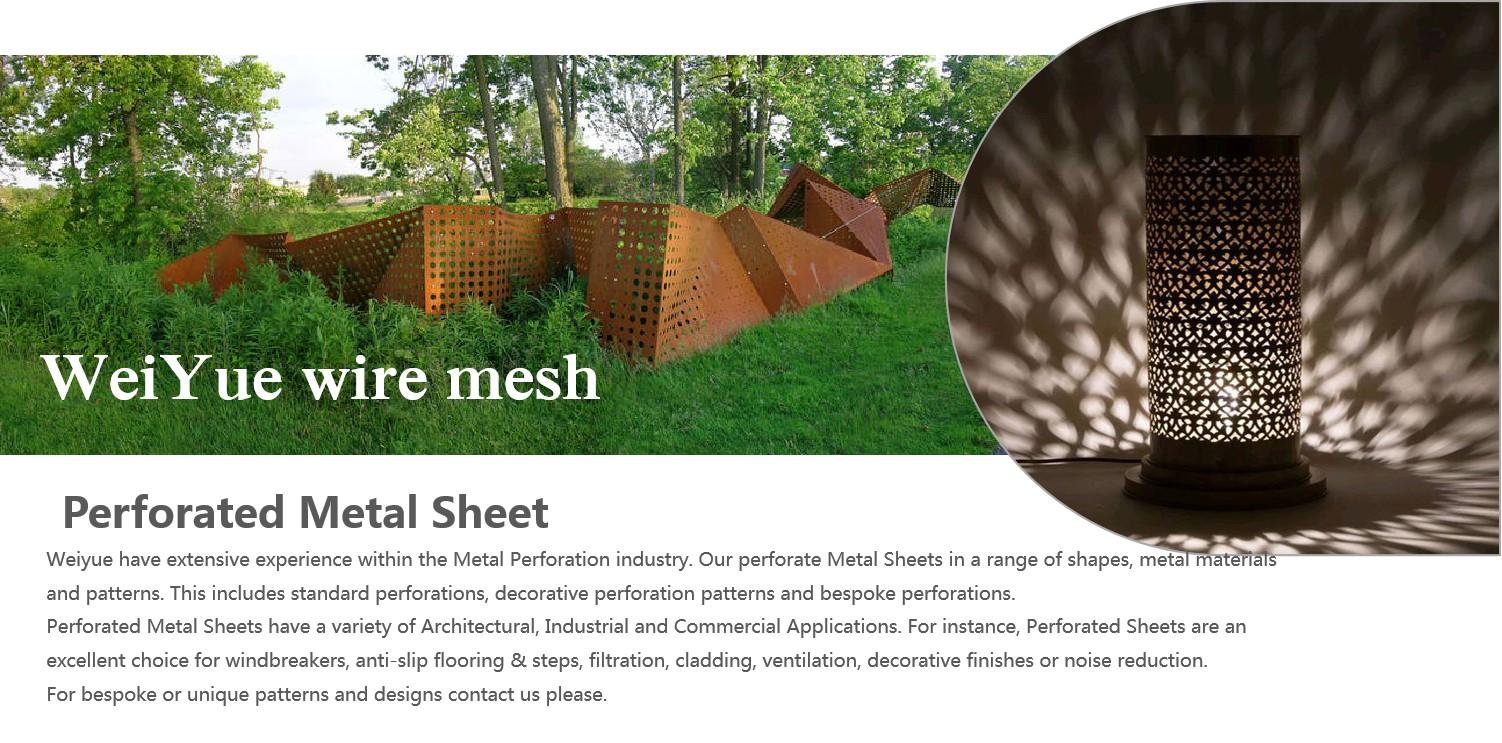

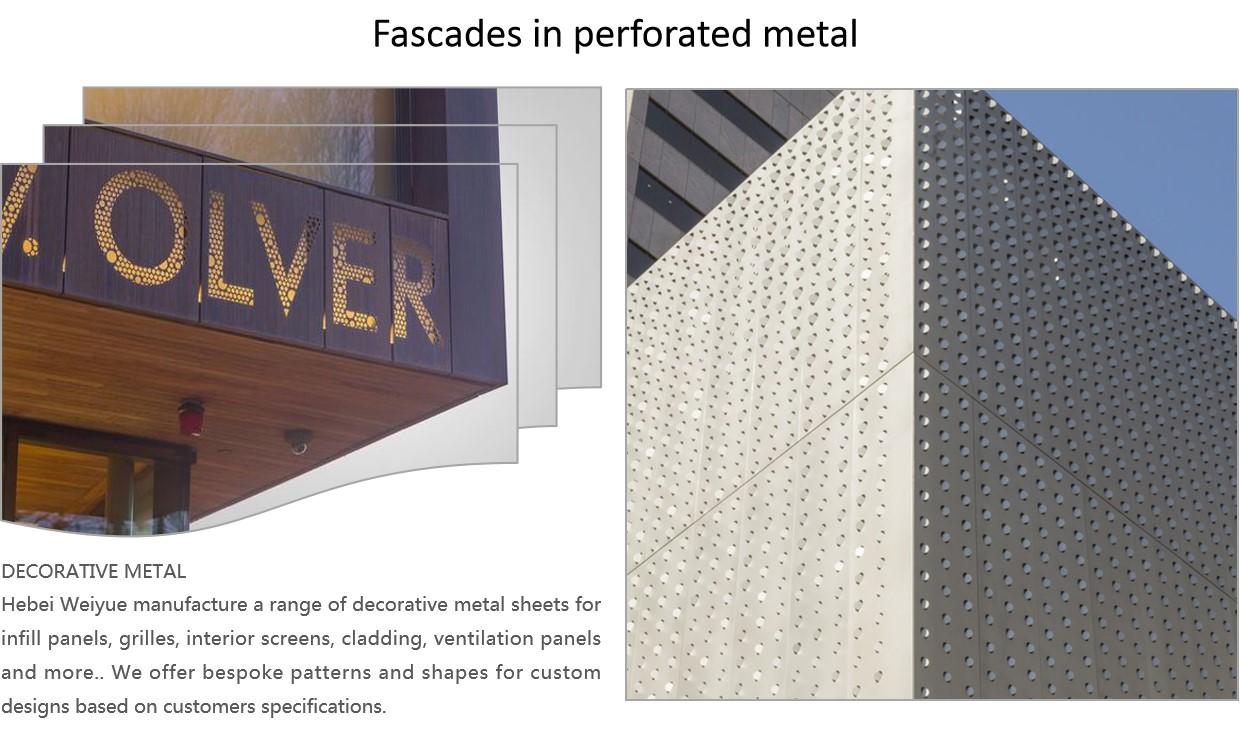

Product Description

We have some round punched sheets in stock, the size is 1m x 2m,

Please contact me for more information.

Specification

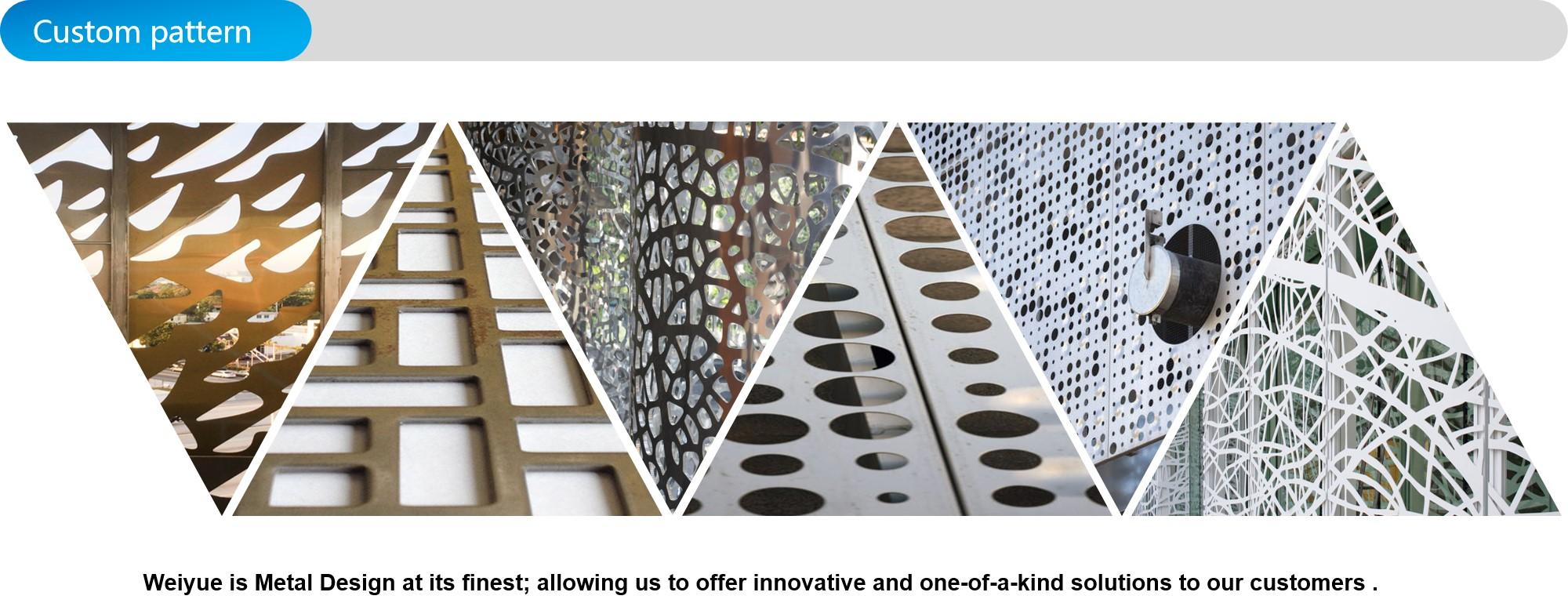

our products | perforated metal mesh |

size | 1) Thickness: 0.3mm-12mm 2) Net length: 1.8m - 2.44m 3) Mesh width: 0.8m - 1.22m 4) Perforation area percentage: from 7% to 83% |

Opening form | Rhombus, circle, square, triangle, hexagon, etc. |

surface treatment | Electro-galvanizing, hot-dip galvanizing, PVC plastic wrapping, oxidation treatment, etc. |

feature | Corrosion resistance, aging resistance, durability, etc. |

Package | 1.LCL: Wrapped with plastic film and put on pallet 2.FCL: nude 3. Other special packaging according to customer requirements. |

Finishing type

Metal finishing is a demanding task that can have a vital impact on the appearance and durability of the final product. For best results, we recommend that you rely on our finishing services. We offer various types:

ArnoldHorizontalization

Anodizing is an electrolytic process used to increase the thickness of the naturally occurring oxide layer on many metal surfaces. Typically used with aluminum, anodizing utilizes the inherent properties of aluminum oxide to create a hard, corrosion-resistant surface. Anodized aluminum has an attractive metallic sheen and can be clear or dyed in a variety of colours.

Clear Coat (Anodized)Clear anodizing is a process that creates a thin coating of aluminum oxide on aluminum metal without the use of dyes or pigments.electrophoresisElectrophoresis is an electrocoating or electrocoating process used to deposit paint or varnish coatings.platingThe most common method of galvanizing is the electrochemical deposition of zinc alloys. Because this process produces a relatively thin layer of galvanization, painting is generally recommended for exterior applications to provide the best corrosion resistance.hot dip galvanizedParts pass through a bath of molten zinc, which provides a thicker zinc coating at a higher cost than electroplating. Hot-dip galvanizing produces a characteristic crystalline pattern or "spangle" on the surface.brushGalvanized steel is dipped in a phosphate bath to provide additional corrosion protection and improve paint adhesion.paint lockGalvanized steel with a zinc coating, deposited by electron deposition followed by chemical treatment to improve adhesion of painted or powder coated finishes.platingElectroplating refers to a variety of processes that deposit a metallic coating on the surface of another metal. Plating materials can be selected for their aesthetics, corrosion resistance, hardness, and various other purposes. Examples include gold, silver, chromium, zinc, tin, cadmium, etc. Plating techniques also vary, including electroplating and electroless plating methods. Contact us to discuss plating materials and methods for your project.powder coatingPowder coating is an electrostatic process used to spray dry powdered materials such as polyester, polyurethane or epoxy resins. The piece is then heat cured, allowing the materials to flow together to create the final finish. Powder coating is usually thicker and more durable than paint, but can be a bit more expensive depending on the project. Available in a variety of colors. Large sheets and coils, corrugated parts, finished components and even special designs – Precision Perforation can apply almost any surface treatment to perforated parts, as long as we determine that the surface treatment is suitable for the material. Contact us to discuss your finishing ideas and questions.

Our culture

product display

VIEW MORE

YOU MAY LIKE