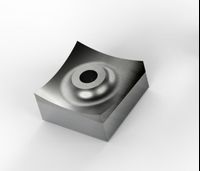

Plastic extruder with a 25 mm screw

- $200.00 / 1 - 100 sets

$199.00 / >=101 sets - 1 set

- Ningbo Asia Screw Machinery Co., Ltd.

- Zhejiang, China

- Ms Dilisa Luo

PRODUCT DETAIL

| Main selling point: | Patented product | Health status: | new |

| Marketing Type: | New Products 2020 | Weight (kg): | 1 |

| application: | extrusion | port: | Ningbo |

| Material: | ABS | Showroom location: | Canada, Turkey, France, Germany |

| Warranty: | 1.5 years | payment terms: | wire transfer |

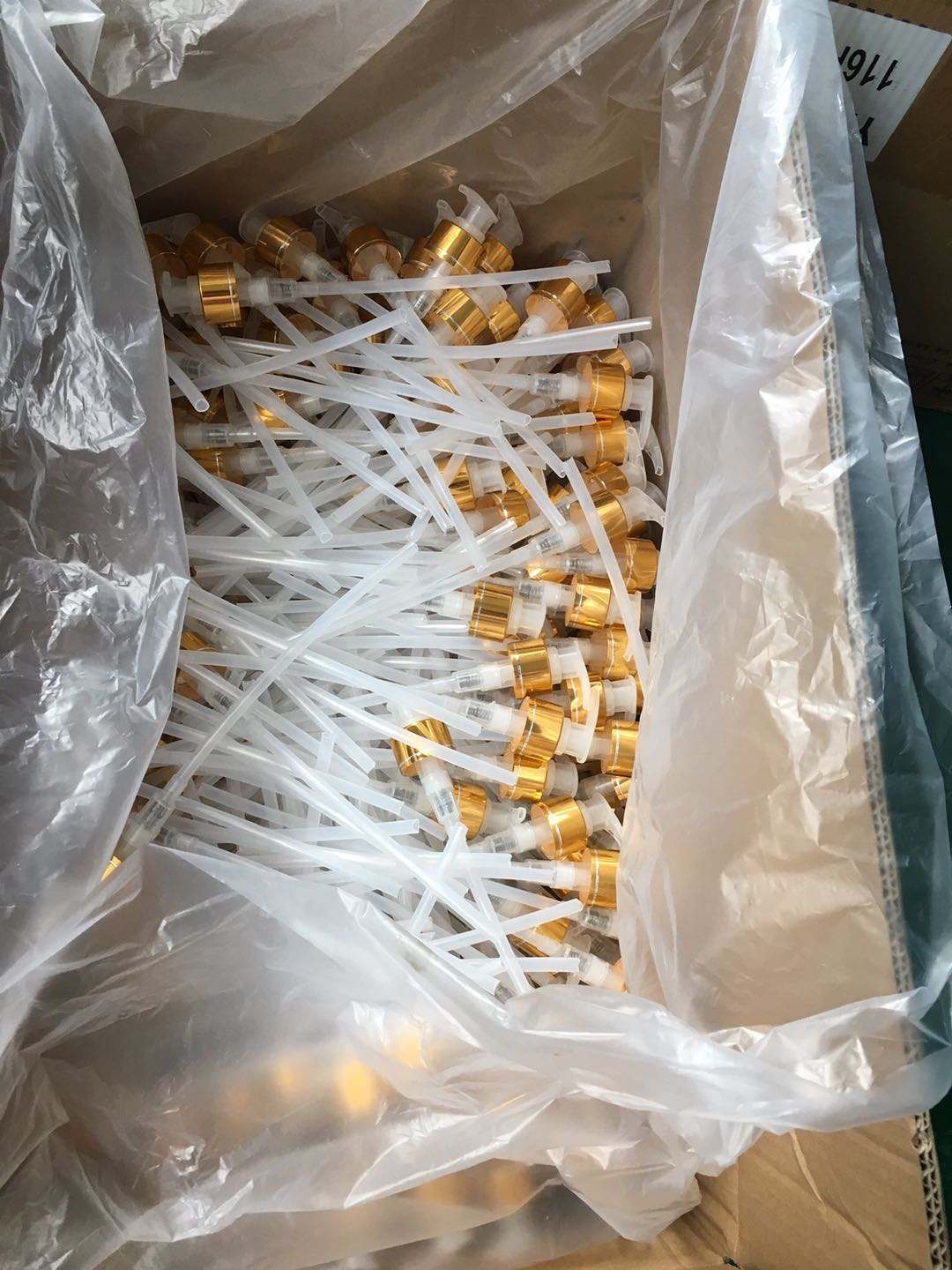

| Plastic Processing: | PE PP PVC ABS PA etc. | Packaging Preview: | |

| Applicable industries: | Hotel, mechanical repair shop, home | Packaging Details: | wooden box |

| Mechanical test report: | if | Video external inspection: | if |

| Supply capacity: | 20 sets per month | place of origin; place of origin: | philosophical |

| Spare Parts Type: | tighten |

Product Description

We have different kinds of extruders, dies,

what do you need

what do we have

Manufacturing Technology

As a common single screw laboratory extruder, the single screw laboratory extruder is used in the plastics processing industry. what is its principle

and structure? Next, analyze the conveying section, compression section and metering section of the extruder

Principle of small single screw extruder. The effective length of the micro single-screw extruder is generally divided into three types

part. The effective length of the three sections is determined according to the screw diameter, pitch and screw depth.

Generally, each section is divided into one-third. The small plastic extruder adopts a first-level overall design to strengthen plasticization

Function to ensure high speed, high performance and stable extrusion, special barrier integrated mixing design to ensure mixing

High shear, low melt plasticizing temperature ensures high performance, low temperature and

Low pressure metered extrusion of materials. Design concept and features: high speed and high output

Flatness and straightness.

and structure? Next, analyze the conveying section, compression section and metering section of the extruder

Principle of small single screw extruder. The effective length of the micro single-screw extruder is generally divided into three types

part. The effective length of the three sections is determined according to the screw diameter, pitch and screw depth.

Generally, each section is divided into one-third. The small plastic extruder adopts a first-level overall design to strengthen plasticization

Function to ensure high speed, high performance and stable extrusion, special barrier integrated mixing design to ensure mixing

High shear, low melt plasticizing temperature ensures high performance, low temperature and

Low pressure metered extrusion of materials. Design concept and features: high speed and high output

Flatness and straightness.

VIEW MORE

YOU MAY LIKE