Rotary Multi-Station Disposable Container Screen Printing Machine Plastic Cup Automatic Screen Printing Machine

- $5800.00 / 1 - 4 sets

$5500.00 / >=5 sets - 1 set

- Hangzhou Taoxing Printing Machinery Co., Ltd.

- Zhejiang, China

- Mr Wayne Wang

PRODUCT DETAIL

| Video external inspection: | if | payment terms: | L/C,Western Union,T/T |

| port: | Shanghai/Ningbo | company advantage: | 20 years |

| Core components: | programmable logic controller | Auto grade: | semi-automatic |

| Packaging Details: | wooden box | Certification: | Chief Executive |

| Voltage power: | 220v | Packaging Preview: | |

| After-sales service provided: | Online support, free spare parts, video technical support | Gas source: | 6bar |

| color: | 1 color | Warranty: | 1 year |

| Package: | wooden packaging | usage: | Tube Printer, Cup Printer |

| printing speed: | 1200PCS/hour | weight: | 130kg |

| Main selling point: | high accuracy | application: | printing bottle |

| Dimensions (L*W*H): | 730*580*128(mm) | Core Components Warranty: | 2 years |

| Plate type: | screen printing machine | Mechanical test report: | if |

| Maximum print size: | 380*200(mm) | Supply capacity: | 100 desktop manual cold laminating machines per month |

| Voltage: | 220V , 110V | Colors and Pages: | monochrome |

| transportation: | ocean | place of origin; place of origin: | Zhejiang, China |

| Health status: | new | brand: | peach star |

| Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Manufacturing Plants, Machinery Repair Stores, Food and Beverage Plants, Farms, Restaurants, Home Use, Retail, Food Stores, Printing Stores, Construction Works, Energy and Mining, Food and Beverage Stores, Advertising Agencies |

machine description

Disposable Container Screen Printing Machine for PP PET PVC Paper Plastic Cups

application

Semi-automatic cylindrical printing machineSuitable for surface printing of cylindrical objects and oval objects, such as glass bottles, blow molded bottles, cosmetic tubes, aluminum water bottles, drum sticks, glass straws, etc.

TX-8T Screen Printer Specifications | ||||||

Maximum print area rounds: | 120mm diameter | |||||

Maximum print area ellipse: | 380mm arc length | |||||

Maximum print length: | 200mm | |||||

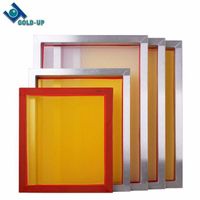

Maximum screen frame size: | 430*280mm | |||||

Print cycle speed: | 1200/hour | |||||

power supply: | 110V/220V 50-60Hz 60W | air pressure: | 5-6Ba | |||

aspect: | 73x58x128cm | weight: | 130KG | |||

main feature

1. Pneumatic control with shock absorber

2. Microprocessor control - PCB

3. Vertical part lifting belt height adjustment

4. Rodless cylinder controls the printing stroke

5. X/Y/R positioning pendant table

6. Linear ball bearings on hardened shafts

7. The scraper is inclined, inclined and height adjustable

8. The screen frame angle and inclination are adjustable

9. Synchronized bottle inflation system with regulator

10. Adjust the scraper pressure with a pressure gauge

11. Motor graders and casters

12. Foot switch control

Machine Details

Circular printing unit with opening and closing device

Pneumatic print head with fine adjustment and automatic lift for screen changing and cleaning

Screen printing head

Simple operation, automatic lifting and lowering of squeegee, ink, worktable, balance squeegee, ensure printing pressure

balanced.

balanced.

Frame clip

The worktable and screen frame can be up and down, left and right, front and rear fine-tuning, high printing accuracy

Easy and fast adjustment

Easy and fast adjustment

printing samples

coffee cup printing | paper cup printing | Red wine glassprint | Oval Object Printing |

VIEW MORE

YOU MAY LIKE