Rubber Interlock Tiles Floor Vulcanizing Curing Press Making Machine

- $4000.00 /set

- 1 set

- Qingdao Steady Machinery Co., Ltd.

- Shandong, China

- Mr Bob Cheng

PRODUCT DETAIL

| Packaging Detail: | Rubber Tiles Floor Vulcanizing Curing Press Fixed into container and proper treatment for big size machine. Fumigation Free Box with Pallet base for small size. Size: depends on concrete model purchased; | Power (kW): | 6-20; |

| Supply Ability: | 20 Sets per Month Rubber Tiles Floor Vulcanizing Curing Press professional maker; | Core Components: | PLC,Motor,Pressure vessel,Pump; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Voltage: | 380V/50HZ; |

| Applicable Industries: | Manufacturing Plant; | Machine Type: | Plate Vulcanizing Press; |

| Warranty of core components: | 1.5 years; | Place of Origin: | Shandong, China; |

| Local Service Location: | United States,Romania,South Africa; | Keywords: | rubber tiles vulcanizing press; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,PayPal, Ali E-pay; | Video outgoing-inspection: | Provided; |

| Dimension(L*W*H): | (L)3230*(W)1150*(H)2400mm; | Brand Name: | STEADY; |

| Condition: | New; | After-sales Service Provided: | Engineers available to service machinery overseas,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; |

| Package Preview: | ; | Machinery Test Report: | Provided; |

| Application: | Vulcanizing Rubber Products; | Certification: | ISO ,CE, Gost; |

| Showroom Location: | United States,Romania,Australia; | Weight: | 1500-90000kg; |

| Name: | Rubber Tiles Floor Vulcanizing Curing Press; | Port: | China Port; |

| Warranty: | 1.5 years; | Key Selling Points: | Long Service Life; |

| Marketing Type: | New Product 2020; |

Company Profile

Product Description

Rubber Interlock Tiles Floor Vulcanizing Curing Press Making Machine is rubber press machine used to make rubber tiles.

The machine has different size for choice according to customers rubber tile size.

Below pictures are rubber floor paving effect for reference. If you have any desired pattern, just send us photos.

Machine Making Procudure

1. Design and making drawing.2. Processing machine parts strictly as per drawings, every process must have checking and control by

worker themselves.

3. QC team checking quality and precision degree.

4. Installaton the rubber hot press machine.

5. Commissioning

6. Packing while book shipping.

7. Delivery, loading container.

worker themselves.

3. QC team checking quality and precision degree.

4. Installaton the rubber hot press machine.

5. Commissioning

6. Packing while book shipping.

7. Delivery, loading container.

Rubber Tile or Other Rubber Products Making Procedure

Up mold and down mold consist a pair mold. When use the machine make the production. 1. Put rubber raw material into every cavity

of the down mold.

2. Press the mold close button on the machine.

3. The machine will close the mold, gives pressure and temperature.

4. When the set work time get out, the machine will open the mold automatically.

5. Workers get the finished rubber products out.

6. Do the next working cycle.

of the down mold.

2. Press the mold close button on the machine.

3. The machine will close the mold, gives pressure and temperature.

4. When the set work time get out, the machine will open the mold automatically.

5. Workers get the finished rubber products out.

6. Do the next working cycle.

Detailed Images

We pay all effort in every detail production, from parts machining to installation and commissioing, to delivery, this ensures our machines are popular in international market.

Heating Plate Technology

Heating plate machining, drilling, grinding and heat treatment, ensures surface hardness and quality in use.

PIston Processing

Piston adopts chilled hard cast iron, high precision machining and fine grinding treatment. Ensures the piston is super wear-resistant and durable in service life.

Valves

All valves adopted are international quality, which ensures the valves moments are accuracy, reliable, trustworthy, and long servive life.

Electronics

electronics adopts Schneider or CHNT brand. And our wire layout desing is very scientific.

So the machine electronics is very reliable even in the harsh working condition.

So the machine electronics is very reliable even in the harsh working condition.

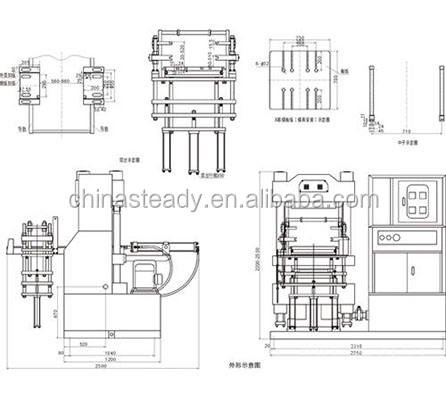

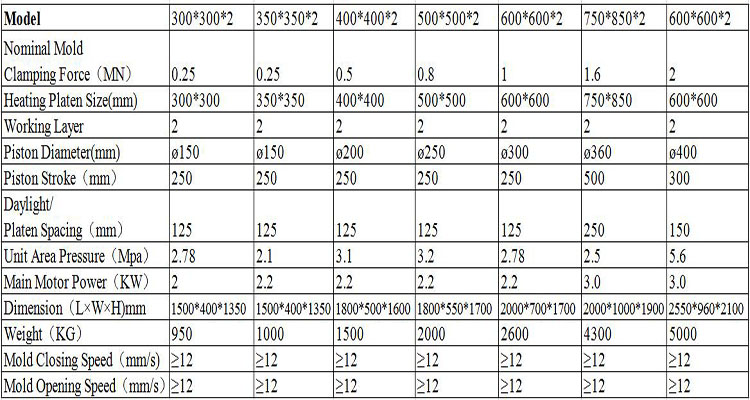

Size Information

Below sizes are just for reference, please us the rubber tiles sizes you want to make, we can give our proposal for you.

Related Products

Certifications

Packing&Shipping

If the ordered quantity is not enough to a full container load, we'll use fumigation free wooden box with pallet base to ship the machine. Which is strong in long time sea transportation even with transshipment. If the rubber press machine ordered get to full container load, we'll directly use container comet to my factory to load them.

Related Goods Loading

Customer Photos

After Sales Service

Technical Support

Training customers‘ how to use the machine and how to make the production. And machine maintenance. And according to customers'

condition, we can help customers decide what configuration machine to use.

condition, we can help customers decide what configuration machine to use.

VIEW MORE

YOU MAY LIKE