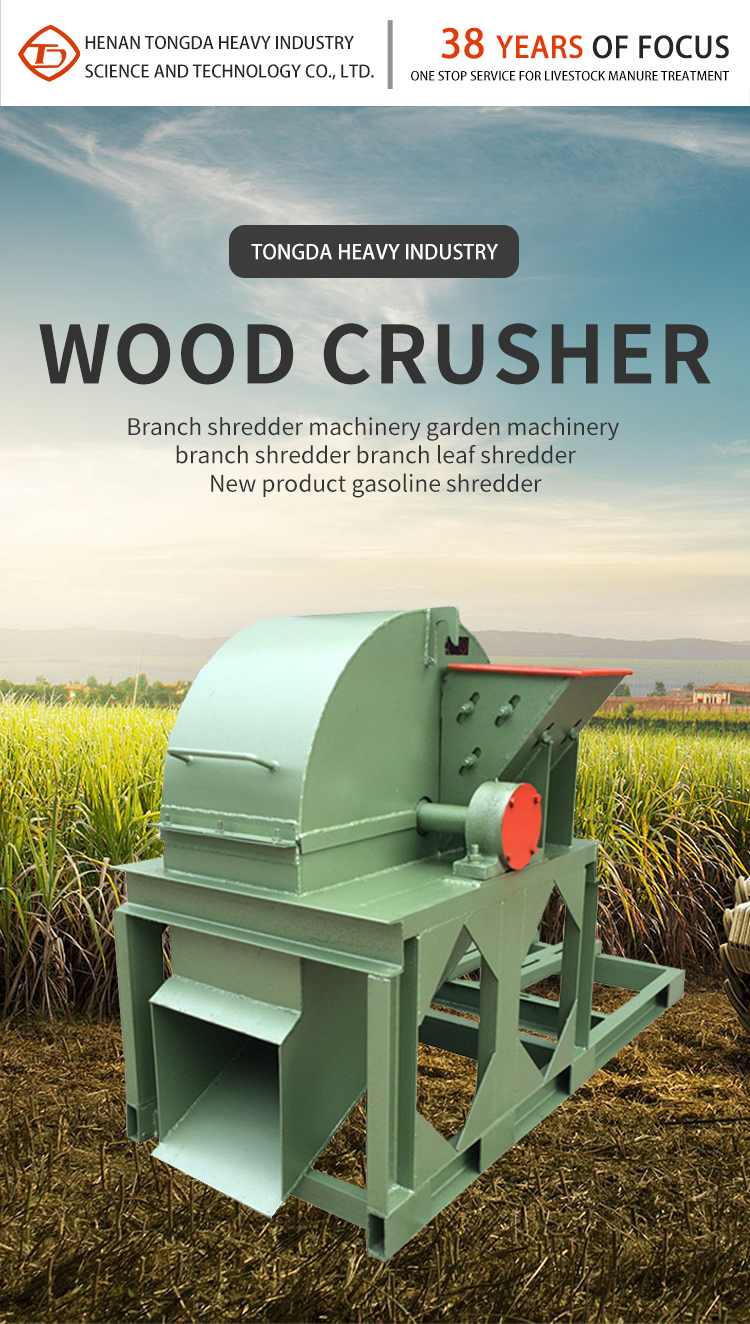

Sawdust Portable Hammer Mill Wood Shredder Biomass Shredder

- $950.00 / 1 - 9 sets

$750.00 / >=10 sets - 1 set

- Henan Tongda Heavy Industry Science And Technology Co., Ltd.

- Henan, China

- Ms TD- Billie

| Main selling points: | high productivity | Mechanical test report: | if |

| Name: | wood crusher | pack: | 3500(mm) |

| Supply capacity: | 100 sets per month | Core component warranty: | 1 year |

| Power type: | electrical | Packaging Details: | Competitive Price Vertical Fertilizer Pan Mixer For Sale Suitable For Shipping By Sea Or Land Or As Customer Requirements |

| payment terms: | Western Union, D/P, D/A, T/T | Video shipment inspection: | if |

| Marketing Type: | New Products 2020 | After-sales service provided: | online support |

| suitable: | wood | Core components: | PLC, gearbox, motor |

| color: | customizable | Local service location: | not any |

| Voltage: | 380 | Applicable industries: | farm, home use, construction |

| strength: | 18.5-2*90KW | brand: | Mastery |

| Health status: | new | port: | Shanghai, Qingdao |

| place of origin; place of origin: | Henan, China | Showroom location: | not any |

| Weight (kg): | 1000 | Warranty: | 1 year |

| Raw materials: | waste wood |

The wood shredder has a compact structure. All-material thickened steel plate parts, wear-resistant, high-quality, hydraulically forced deceleration, stable performance, high safety, and high production efficiency. Fragments of a woody material such as logs, branches, trunks, reed stalks, leftovers, etc. Complete functions, strong crushing capacity and good crushing effect.

Wood flour machine structure and crushing principle:

1. The wood flour machine is composed of three parts: the body, the middle body and the lower body.

2. The crushing knife is composed of 7-type knife, 1-type knife and centrifugal knife.

3. The auxiliary machine is composed of fan, powder collector and dust collector.

4. The crushing cavity of the main machine adopts 7 knives, 1 knives, and centrifugal knives. There are coarse crushing, fine crushing and centrifugal reciprocating crushing. The motor drives the rotor of the crusher to run at high speed, so that the machine generates high-speed airflow and produces high-strength crushed materials. Impact force, compression force, cutting force, friction force, realize unique crushing function.

5. During the cutting and crushing process of the three blades, the rotor generates high-speed airflow that rotates with the direction of the blades. The material is accelerated in the airflow, repeatedly impacted and cut by friction. At the same time, they are subjected to three crushing effects. The pulverized material enters the analyzer along with the airflow. Analysis, due to the centripetal force when the airflow is subjected to the centrifugal force of the analyzer rotor, when the centrifugal force is greater than the centripetal force, the fine particles will enter the powder collector with the airflow for collection, and the coarse particles will enter the centrifugal gun crushing chamber and continue to crush until you are satisfied. fineness.

| Model | 420 | 500 |

| Cutter diameter(mm) | 400 | 450 |

| number of blades | 4 | 4 |

| Spindle speed(mim/h) | 2800 | 2600 |

Other Products

-

The latest design of organic urea fertilizer production equipment$3100.00 - $6300.00 / set

The latest design of organic urea fertilizer production equipment$3100.00 - $6300.00 / set