Single Column CNC Servo Electronic Press Auto Parts Pressure Test Single Arm Press

- $5000.00 /set

- 1 set

- Dongguan Hongjin Test Instrument Co., Ltd.

- Guangdong, China

- Mr Hongjin Test Machine

PRODUCT DETAIL

| Voltage: | 220~380V | Maximum (kg): | 100~30000 |

| Repeatability (mm): | 0.01 | Power(Kw): | 0.4~11KW |

| place of origin; place of origin: | Guangdong, China | Customization support: | OEM,ODM,OBM |

| Maximum (mm): | 200~500 | Packaging Details: | Export fumigation-free wooden box |

| brand: | Hong Jin | port: | Shenzhen, Guangzhou |

| brand: | Red Brocade | Fast forward/rewind (mm/s): | 0~50/0~30 |

| Press fit (mm/s): | 0~35/0~15 | Warranty: | 1 year |

| Allowable range (kg): | 1~100/300~30000 | Supply capacity: | 5 groups per day |

| Package preview: | Setting unit (mm): | 0.01 | |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram, Paypal |

Product Description

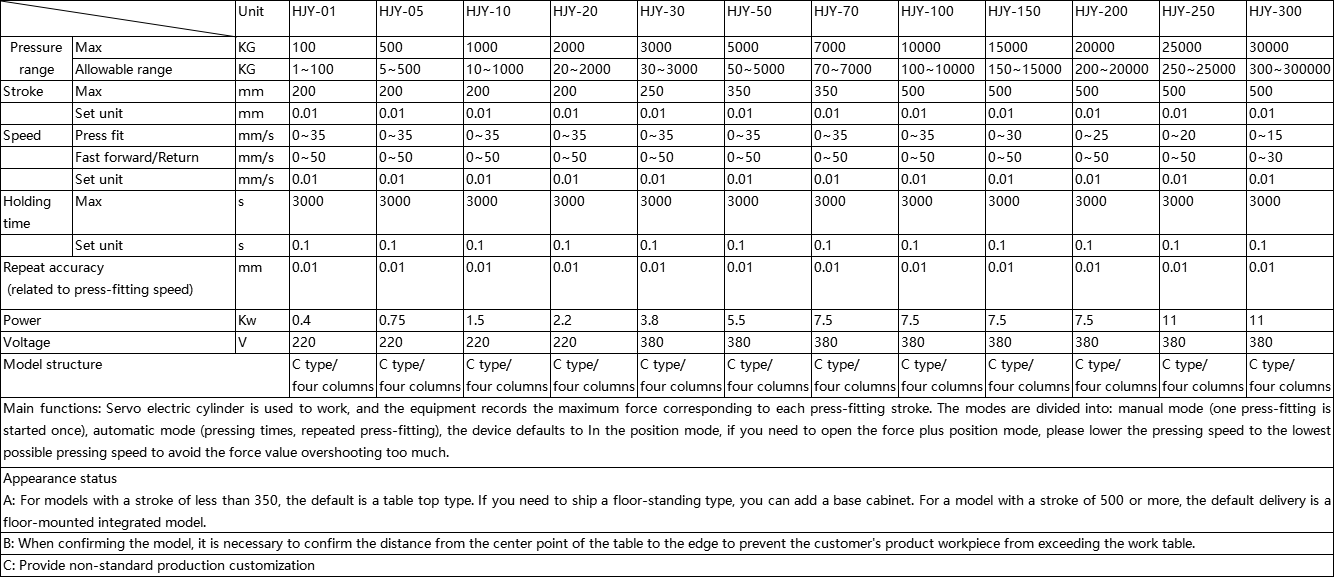

Precision CNC servo electronic presses are referred to as electronic presses/servo presses. Its working principle is that the servo motor drives the high-precision ball screw to perform precision press-fitting operations. It can realize the full closed-loop control of the pressing force and pressing depth in the stamping assembly operation. Application fields: precision assembly application of auto parts, precision assembly application of electronic products, precision assembly application of core components of IT and photography technology, precision pressure test application. The equipment is composed of base body sheet metal, precision servo electric cylinder, servo system, control system and so on. The special plane has high working efficiency, stable operation, low noise, high pressure precision and convenient control.

feature

1. Improve productivity The stroke length can be set to the lower limit value required for production. A speed suitable for processing content can be maintained. 2. The product has high precision. Through closed-loop feedback control, the accuracy of the set displacement is always guaranteed. Suppress product burrs and prevent defective products. 3. Low noise and long mold life. Through the low noise mode (that is, reducing the contact speed between the slider and the plate), the noise is greatly reduced compared with ordinary mechanical presses. Moreover, the mold vibration is small and the service life is long. 4. Controllability of slider movement Users can use this function to program the slider movement mode suitable for the processing technology, which can effectively improve the accuracy and stability of the product, improve the life of the mold and production efficiency, and can realize silent punching and even enlarged processing Range (such as magnesium alloy). Suitable for processes such as stamping, punching, deep drawing, embossing and bending, as well as characteristic curves of different materials. If the slider can be stopped for holding pressure, the purpose is to improve the molding quality of the workpiece. 5. Energy saving and environmental protection The flywheel, clutch and other energy-consuming parts of the traditional mechanical press are eliminated, the transmission parts are reduced, and the mechanical transmission structure is simplified; the amount of lubricating oil is less, and the stroke is controllable; due to the low power consumption, compared with the hydraulic press , and the operating cost is also greatly reduced. Much cleaner, no greasiness problem.

Product parameters

strength | 0.4~11Kw |

Voltage | 220~380V |

model structure | Type C/Four Posts |

Repeatability (related to pressing speed) | 0.01mm |

product display

VIEW MORE

YOU MAY LIKE