Small plastic injection products manufacturing company

- $1.35 / >=1000 pieces

- 1000 pieces

- Shenzhen Wt Hardware And Plastic Limited

- Guangdong, China

- Mr Henry Yang

PRODUCT DETAIL

| Plastic molding type: | injection | Package preview: | |

| payment terms: | L/C, Western Union, T/T, MoneyGram, Alipay, paypal, Trade Assurance | Maximum part weight: | 5800g/13 lbs |

| Package: | standard carton | Surface treatment: | Polished/textured/glossy/matte/painted |

| product material: | ABS/ PC/ PP/ nylon+glass fiber/PE/acrylic | Mold life: | 500,000 shots |

| Plot format: | STEP/STP/IGS/XT/STL/CAD/PDF/DWG etc. | brand: | WT |

| Certification: | ISO9001:2008 | Origin: | Guangdong, China (Mainland) |

| model: | custom made | Mold material: | P20/718/738/NAK80/S136 |

| Processing services: | forming | Supply capacity: | 100000 pieces per month |

| Maximum part size: | 1500*1500mm*1000mm | port: | Shenzhen |

| Packaging Details: | Product packaging method: 1-Wrapped in plastic bags or pearl cotton protective packaging materials. 2-Put in 5-ply standard export carton with rigid protective layer. 3- Seal the carton with tape. 4- Loaded on pallets with protective rigid corners. 5- Loading container for sea transportation. Remarks: If you need express such as DHL, FEDEX or UPS, no pallet is required | can choose colour: | Customized colors such as Pantone/RAL |

Buyer's Guide

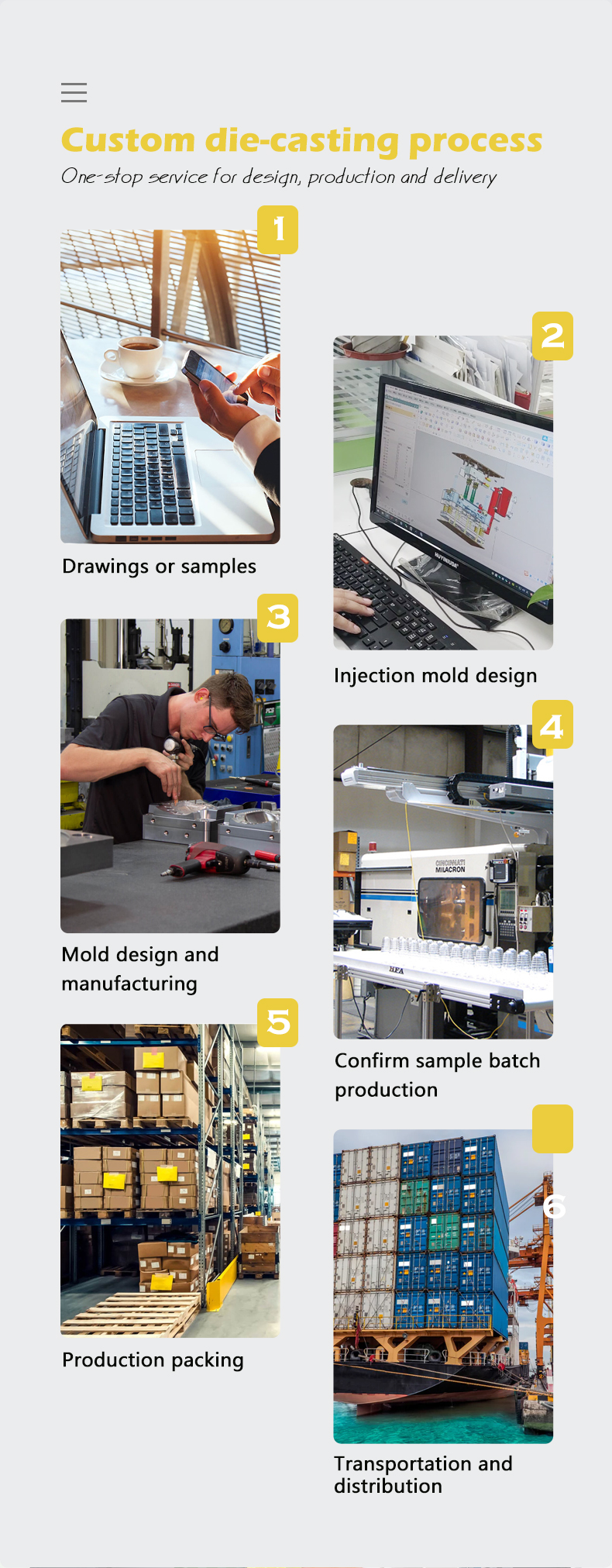

Shenzhen Water Hardware Plastic Co., Ltd. was established in 2011, is a professional

(Injection molds, injection molded products, mold research, development, production, sales and service

casting molds and casting products,).

Our products include: auto parts molds (armrest boxes, air-conditioning sockets, carbon tanks, inspection mirrors), digital electronic box molds, office supplies molds, medical equipment accessories molds, coffee machine accessories molds, two-shot molds, plastic molds, etc. In addition, we are obtaining ISO9001 certificate, and our products are exported to clients in countries and regions such as the United States, Canada, Germany, Hungary, United Kingdom, Italy, Netherlands, Spain, Singapore, Hong Kong, Australia, Japan, Korea, etc.

We also welcome OEM and ODM orders, our project engineers can provide the following services, from project management, structural design technology to mold design, molding process control, die casting, etc. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements, you are welcome to visit our factory and establish a cooperative relationship.

(Injection molds, injection molded products, mold research, development, production, sales and service

casting molds and casting products,).

Our products include: auto parts molds (armrest boxes, air-conditioning sockets, carbon tanks, inspection mirrors), digital electronic box molds, office supplies molds, medical equipment accessories molds, coffee machine accessories molds, two-shot molds, plastic molds, etc. In addition, we are obtaining ISO9001 certificate, and our products are exported to clients in countries and regions such as the United States, Canada, Germany, Hungary, United Kingdom, Italy, Netherlands, Spain, Singapore, Hong Kong, Australia, Japan, Korea, etc.

We also welcome OEM and ODM orders, our project engineers can provide the following services, from project management, structural design technology to mold design, molding process control, die casting, etc. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements, you are welcome to visit our factory and establish a cooperative relationship.

FAQ

1. Does your company make molds by yourself?

Yes, we are a manufacturer with about twenty years of molding experience.

2. How many kinds of molds can you make? Do you only make molds?

We can manufacture many kinds of molds, such as injection molds, blow molds, stamping molds, die-casting molds and silicone rubber molds. In addition, we can also produce the final parts for you.

3. What software will you use to check the drawings?

What formats of drawings can you check? Both our designers and engineers use AUTO CAD and Soliworks software to check 2D and 3D drawings We can check drawings in PDF, Al, DWG(CAD) and STP(3D) or IGS(3D) formats.

4. Can you send me free samples?

Yes, but you should charge the freight yourself. We can refund the fee if you place bulk order.

5. How to pack the molds and products?

For the mould, we will first apply a layer of anti-rust oil, then cover a layer of film on the mold, and finally pack

Packed into fumigation-free wooden boxes, as for the products, we will pack them into standard export cartons or according to customer requirements.

6. I only have samples on hand, can you also make products for me?

2. How many kinds of molds can you make? Do you only make molds?

We can manufacture many kinds of molds, such as injection molds, blow molds, stamping molds, die-casting molds and silicone rubber molds. In addition, we can also produce the final parts for you.

3. What software will you use to check the drawings?

What formats of drawings can you check? Both our designers and engineers use AUTO CAD and Soliworks software to check 2D and 3D drawings We can check drawings in PDF, Al, DWG(CAD) and STP(3D) or IGS(3D) formats.

4. Can you send me free samples?

Yes, but you should charge the freight yourself. We can refund the fee if you place bulk order.

5. How to pack the molds and products?

For the mould, we will first apply a layer of anti-rust oil, then cover a layer of film on the mold, and finally pack

Packed into fumigation-free wooden boxes, as for the products, we will pack them into standard export cartons or according to customer requirements.

6. I only have samples on hand, can you also make products for me?

Yes, you can send us samples, we can help you make 3D models according to the samples, and finally, we can help you develop items for mass production.

7. My request at the beginning is small batch, can you help me customize my products?

Yes, we can start with smaller quantity because we are a manufacturer.

7. My request at the beginning is small batch, can you help me customize my products?

Yes, we can start with smaller quantity because we are a manufacturer.

VIEW MORE

YOU MAY LIKE