Structural insulated panel MGO SIP Sandwich panel Panel

- $35.00 / >=100 pieces

- 100 pieces

- Zhangjiagang Jiarun Building Materials Technology Co., Ltd.

- Jiangsu, China

- Ms Ailsa Li

PRODUCT DETAIL

| application: | office building | Types of: | sip |

| port: | Shanghai | place of origin; place of origin: | Jiangsu, China |

| usage: | Insulation Wall Panel | connect: | T&G, G&G, four sides closed |

| Packaging Details: | standard wooden pallet | brand: | SC |

| design style: | modern | Supply capacity: | 5000 pieces per day |

| Standard size: | 1220*2440mm, or customized | Function: | sound insulation |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Environmentally friendly: | No asbestos, no radiation |

| feature: | Fire resistance for more than 3 hours | Insulation type: | EPS, XPS, PU, PUR, PIR, etc. |

| Warranty: | 3 years | After-sales service: | online technical support |

| thickness: | 25-300mm | surface: | Mgo board, fiber cement board, OSB board |

| Project solution ability: | overall project solution |

Product Description

Magnesium Oxide Silicone Rubber

MGO SIP Panel Structural Insulation Panel

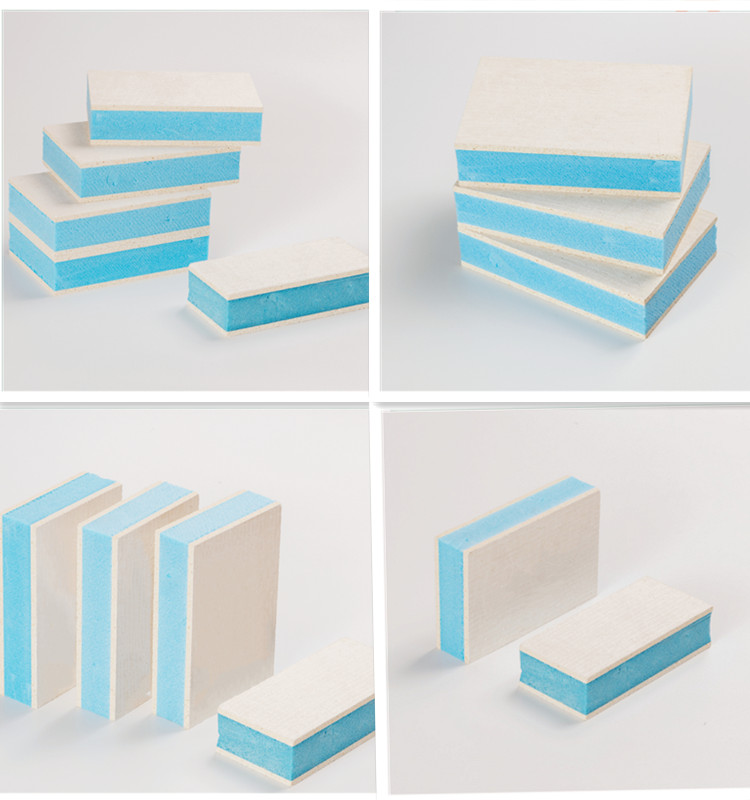

MGO SIP Panel Structural Insulation Panel is a Composite Building Material

It consists of a sandwich of two structural panels with insulating foam in between

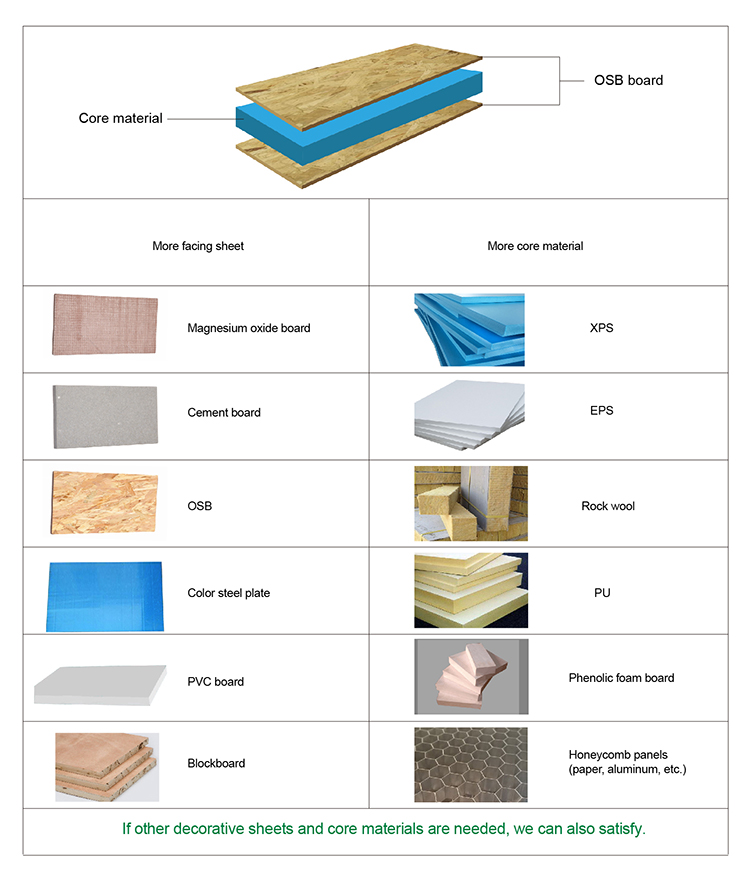

Panel skin options include

* Magnesium Oxide Board (MGO Sulphate Board)

* Fiber cement board (FCB)

* Oriented Strand Board (OSB)

Insulation core options include

* Expanded polystyrene (EPS)

* Extruded polystyrene (XPS)

* Polyurethane (PU)

* Polyisocyanurate (PIR)

* Polyurethane (PUR)

application

MGO SIP Panel Structural Insulation Panels are high performance insulation walls

Applications range from ceilings to floors and everything in between

MGO SIP Panel Structural Insulation Panel is a Composite Building Material

It consists of a sandwich of two structural panels with insulating foam in between

Panel skin options include

* Magnesium Oxide Board (MGO Sulphate Board)

* Fiber cement board (FCB)

* Oriented Strand Board (OSB)

Insulation core options include

* Expanded polystyrene (EPS)

* Extruded polystyrene (XPS)

* Polyurethane (PU)

* Polyisocyanurate (PIR)

* Polyurethane (PUR)

application

MGO SIP Panel Structural Insulation Panels are high performance insulation walls

Applications range from ceilings to floors and everything in between

Substrate | Mgo board+EPS+Mgo board,Mgo board+XPS+Mgo board | ||||

Width (mm) | 600, 1100, 1220 | ||||

Length (mm) | 1100, 2100, 2440, 2600, 2700, 2800, 2900, 3000 | ||||

Thickness (mm) | 25mm-300mm | ||||

Insulation type | EPS, XPS, PU, PUR, PIR,....etc | ||||

fire protection | more than 3 hours | ||||

application | Exterior walls, interior walls, explosion-proof panels, floors, partitions, roofs, prefabricated houses | ||||

Advantage | 100% asbestos free, light weight, easy to install, fireproof, moistureproof, Waterproof, anti-corrosion, energy saving, environmental protection | ||||

technical date | unit | EPS sandwich panel | XPS sandwich panel |

density | kg/m3 | 18-20 | 36-40 |

Thermal conductivity, 90 days, 10℃ | Width/m | ≤0.04 | 0.027-0.03 |

Compressive Strength at 10% Deformation or Yield, (Perpendicular) | kPa | ≥100 | ≤300 |

tensile strength | kPa | ≥100 | ≤300 |

temperature limit | ℃ | -50,+75 | -50,+75 |

Coefficient of linear thermal expansion | mm/mm | / | 0.07 |

water absorption | volume percentage | / | ≥1.00%n |

Capillarity | zero | / | zero |

structure | T&G | cam lock | both sides closed |

T&G

gems and gems

both sides closed

VIEW MORE