The construction material of the sculpture, fireproof calcium silicate board

- $30.00 /piece

- 1 piece

- NICHIAS Corporation

- Tokyo, Japan

- Ms Sachiho Nezu

PRODUCT DETAIL

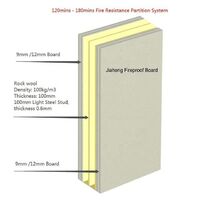

| application: | Aluminium industry, running water tank, holding furnace bath, etc. | Packaging Details: | tray |

| payment terms: | letter of credit, wire transfer | Supply capacity: | 10 pieces per week |

| design style: | industrial | brand: | Tongbao |

| port: | Yokohama Port Narita Airport | Warranty: | not any |

| model: | p15-02 | After-sale service: | other |

| place of origin; place of origin: | Japan | Project Solving Ability: | other |

Product Description

TOMBO NO.4720 LUMIBOARD™ is a diatomaceous earth based calcium silicate thermal insulation material with excellent heat resistance. It has excellent machinability and is ideal as an insulating material for transfer, casting and holding systems such as runners, spouts, floats, header material for hot top rings and die casting holding furnaces in direct contact with molten aluminum.

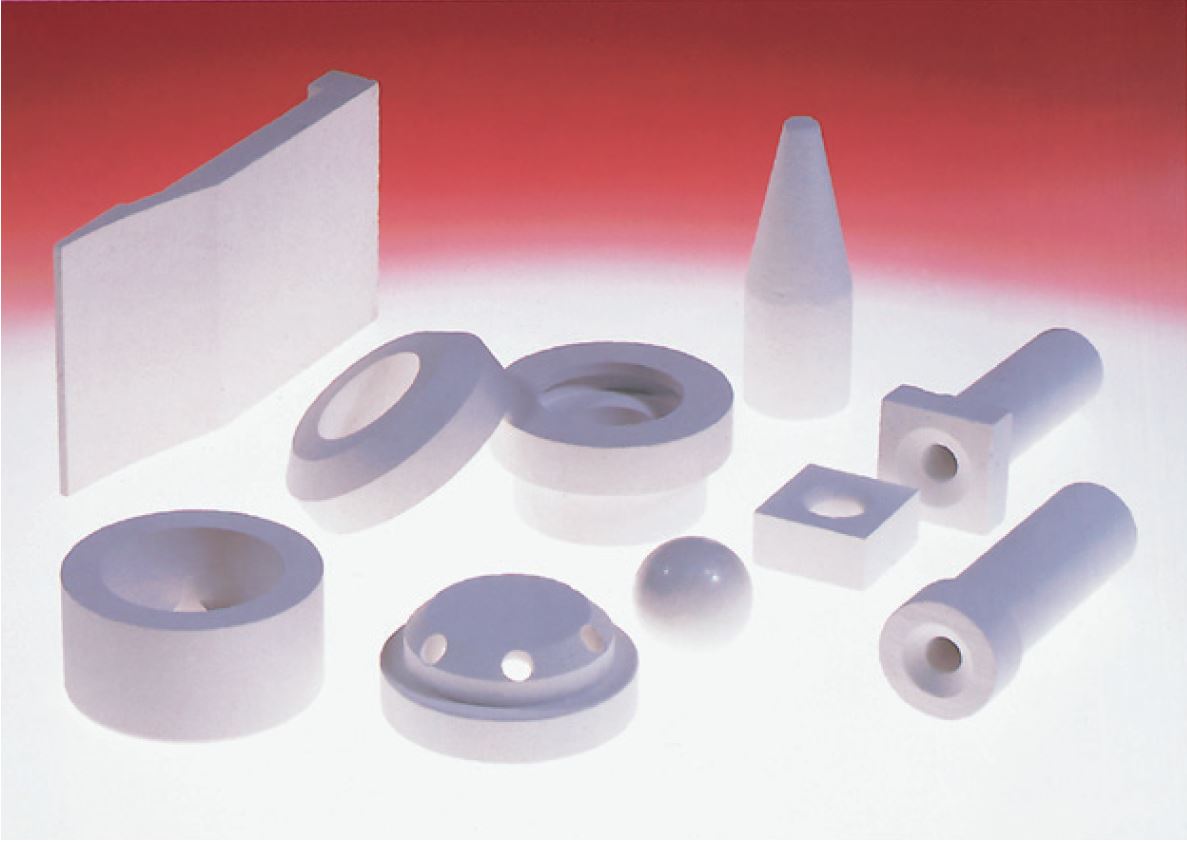

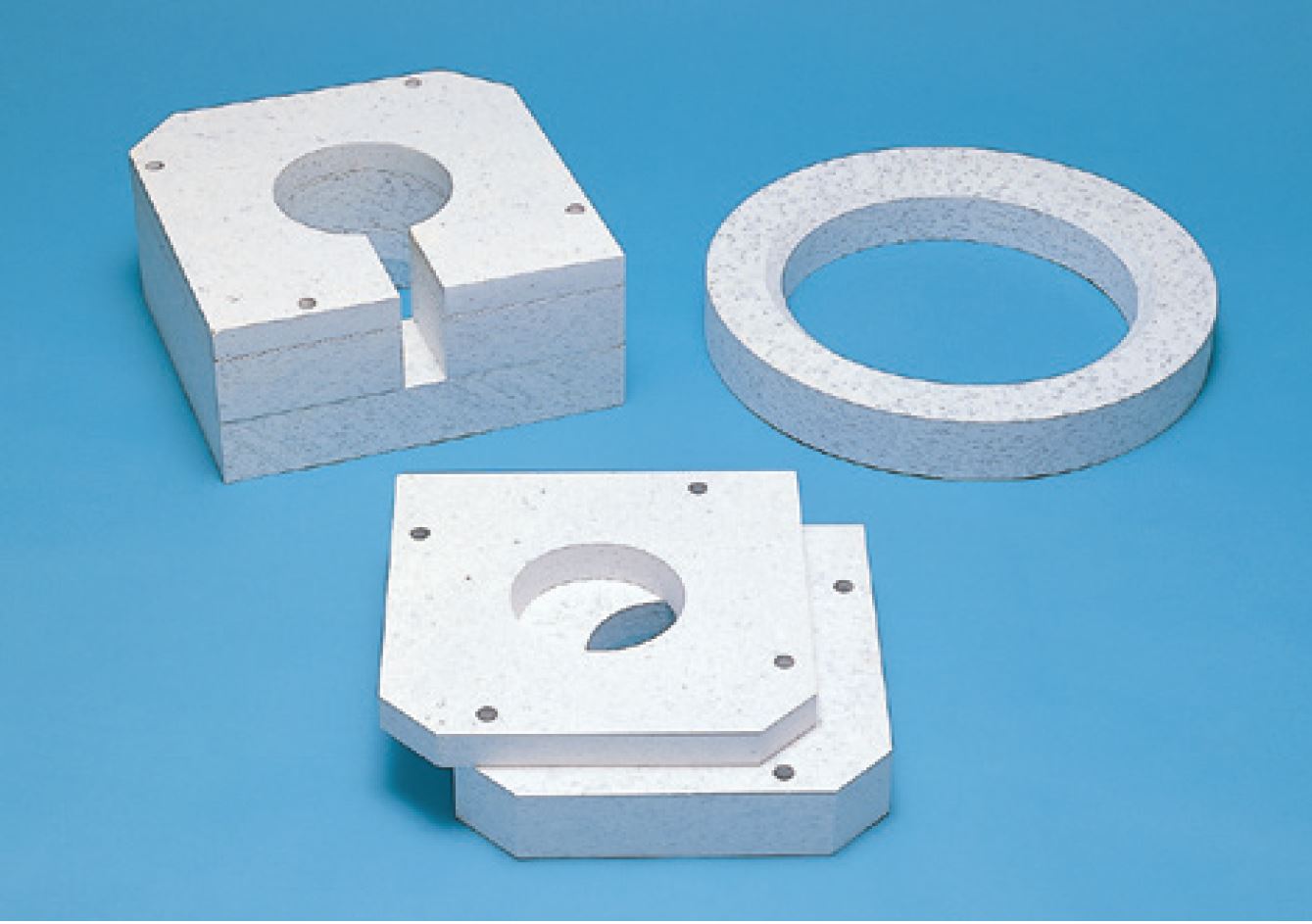

■Advantages ・Low thermal conductivity, low heat capacity When LUMIBOARD™ is used in the launder between the melting holding furnace and the die casting machine, the transfer of molten aluminum can be reduced with a minimum temperature. When LUMIBOARD™ is used in the lining of holding furnaces, energy savings can be achieved by raising the temperature in less time than conventional castables. ・Excellent machinability LUMIBOARD™ can be machined into various shapes such as floats, spouts, hot top ring headers, etc. due to its excellent machinability. ・Easy Removal of Solidified Metal LUMIBOARD™ is not wetted by molten aluminum, so it is easy to remove solidified metal.

■Application of washing tank, holding furnace tank, float, spout, hot top ring header, etc.

■Type We have various types of LUMIBOARD™, and we can recommend the most suitable type for the application. Please feel free to contact us.

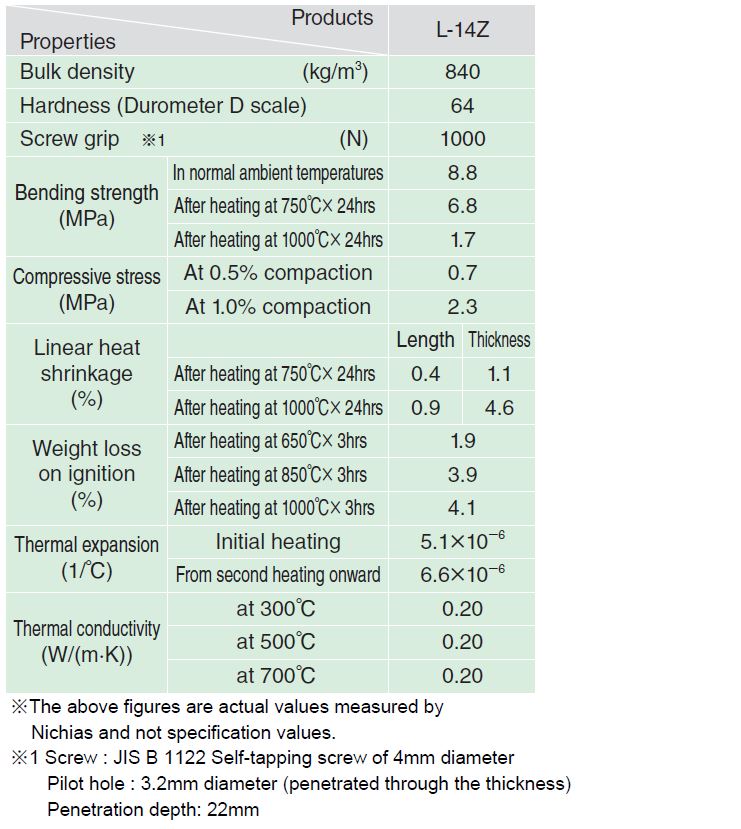

■Physical properties

■Precautions for drying and preheating ・Since the product is shipped dry, when LUMIBOARD™ comes into contact with molten aluminum, moisture absorption during storage and water absorption of caulk during installation may cause cracks. Dry LUMIBOARD™ with an electric stove, heater, or put LUMIBOARD™ in the oven before use. ・Dry the molded product for a heat-retaining furnace bath at about 150°C before raising the temperature. Please raise the temperature at a rate of 25°C per hour, and hold it for 6 to 12 hours at the following points (200°C, 400°C, and 600°C).

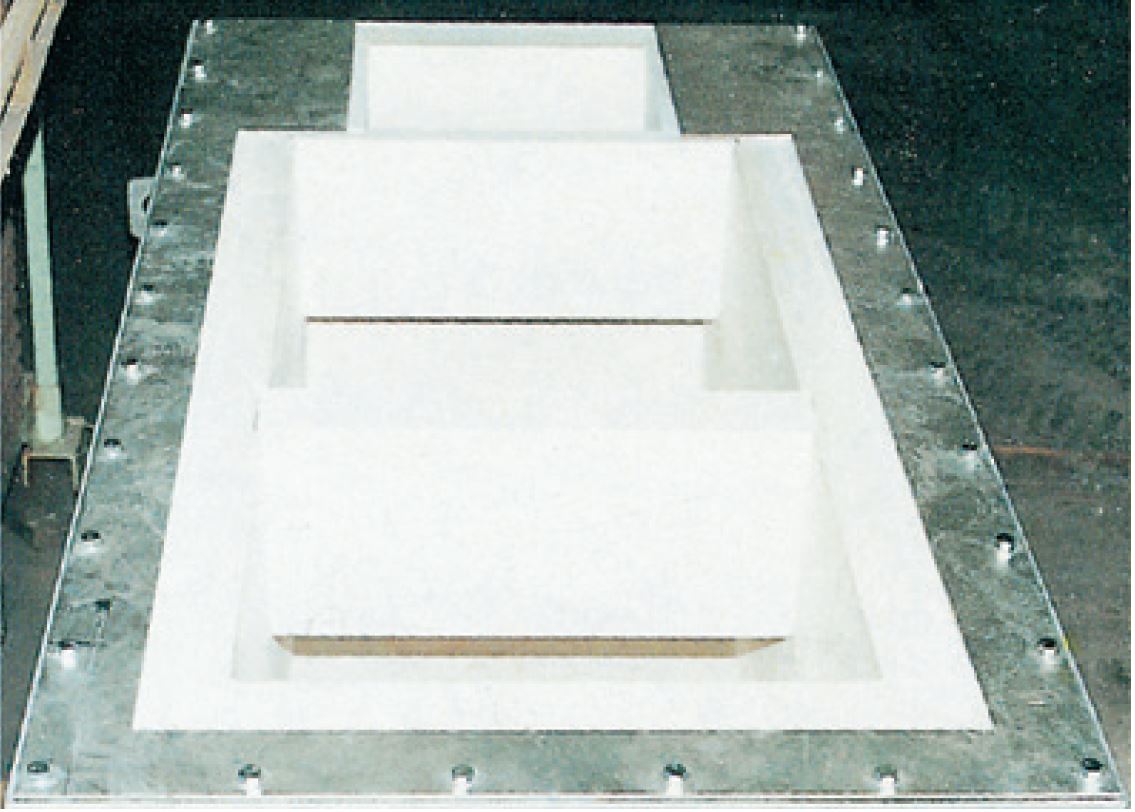

■Application example of holding furnace

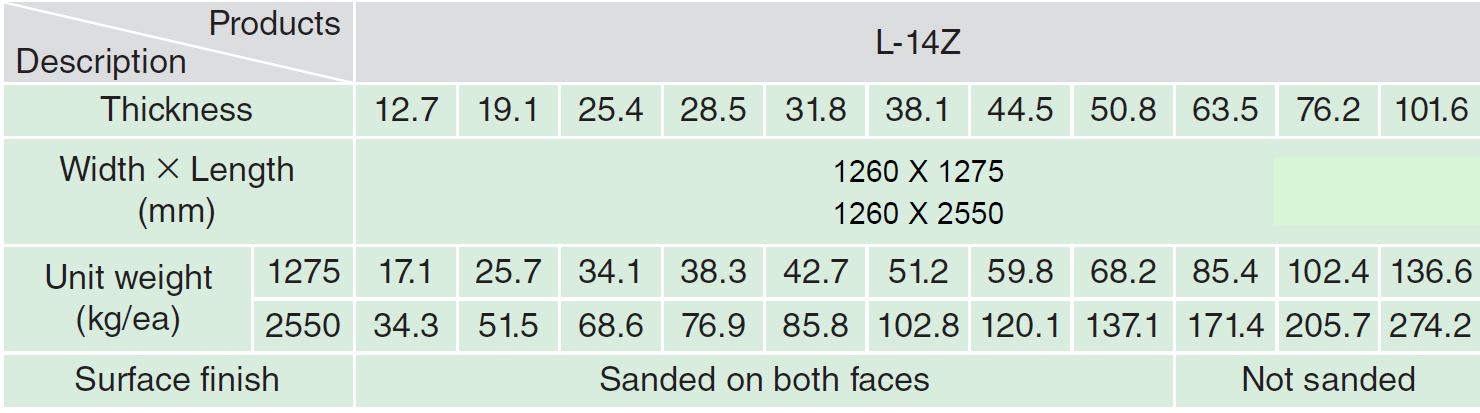

■Standard size

product name | TOMBO No.4720-L14Z LUMIBOARD calcium silicate board |

brand | Tongbao |

place of origin; place of origin | Japan |

VIEW MORE

YOU MAY LIKE