Under-tile waterproof decoupling membrane decoupling pad

- $1.00 / >=3000 square meters

- 3000 square meters

- Weifang Berry Waterproof Material Co., Ltd.

- Shandong, China

- Mr Richard Chan

| type: | Under-tile waterproof decoupling membrane decoupling pad | product name: | uncoupled membrane |

| Function: | Building waterproofing | application: | bathroom, hotel |

| feature: | Anti-aging | Supply capacity: | 1,000,000 square meters/month |

| Certificate: | International Organization for Standardization | Material: | Multiple layers of different materials |

| usage: | bathroom | place of origin; place of origin: | China |

| Warranty: | 5+ years | Reel size: | Width: 1m Length: 5m, 10m, 20m, 30m |

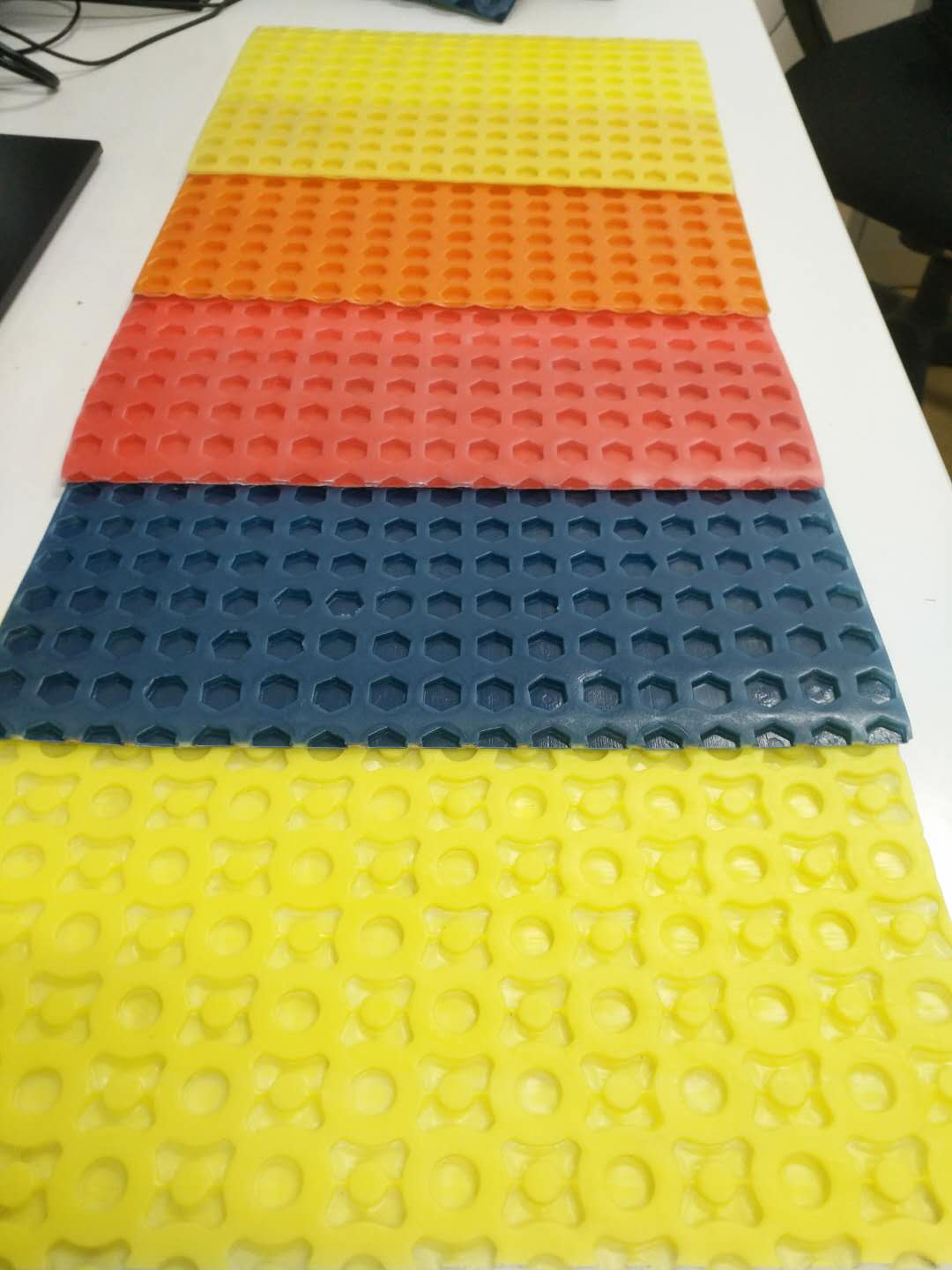

| design style: | modern | color: | yellow, orange, red, blue |

| After-sale service: | Online technical support | payment terms: | letter of credit, wire transfer |

| Packaging Preview: | Project Solving Ability: | Graphic Design, 3D Model Design |

This plastic film system is geometrically configured to provide an air space between the tile and the substrate to allow independent movement between the two and limit the transfer of stress. "BLOSAM UM503 is a polyethylene film with a grid structure of square cavities, each recessed dovetail structure, and anchor fleece laminated to the underside. The anchor fleece is embedded in a thin mortar to provide a mechanical bond to the substrate. The tiles are installed on the UM503 using the thin layer method, so that the mortar UM503 is mechanically fixed in the square shrinkage cavity of the floor mat. Specifically designed for tile and dimension stone installation, the UM503 is used as a decoupling layer, waterproofing membrane and steam management layer, Accommodates moisture under tile coverings. In addition, the UM503 has all of these features while still providing adequate support/load distribution to tile coverings. These four essential features allow for successful tile installation on a variety of substrates, including plywood / OSB, concrete, plaster, heated floors, etc.

This integration of decoupling, waterproofing, load sharing and steam management functions enables consistent results.

product | uncoupled membrane |

Material | Polyethylene (PE) Film; Polypropylene (PP) Nonwoven |

Reel size | 1mx30m/1mx20m/1mx10m |

weight | 550g/sgm |

thickness | 3.0mm |

Package | wrapped in plastic film |

color | orange; yellow; green; blue; or other |

A. Decoupling

It provides decoupling through its open rib structure, allowing in-plane motion, effectively counteracting differential motion stresses between the substrate and the tile, thereby eliminating the major cause of cracking and delamination on the tile surface.

B. Waterproof

It provides reliable waterproofing in interior and exterior applications. Its polyethylene composition protects the substrate from moisture penetration, which is especially important in today's built environment where most substrates are moisture-sensitive.

C. Steam management

A distinguishing feature of this uncoupled membrane is the presence of free space created by the configured channels on the underside of the mat. The free space provides a path for excess moisture and steam to escape from the substrate, which could otherwise damage the tile layer above. Therefore, it effectively manages the moisture under the tile covering.

D. Load distribution

It is virtually incompressible within the tile assembly, achieving the benefits of decoupling without sacrificing point load distribution capabilities. The ability of the membrane installation to support and distribute heavy loads while maintaining the integrity of the tile surface has been proven through extensive laboratory and field testing, including applications exposed to vehicular traffic.

Waterproof membrane for thin tile and stone installation in accordance with US ANSI108.10.

property | testing method | Require | Performance |

Fungal and Microbial Resistance | Film should not support mold growth | go through | |

seam strength | ASTM D751 | 16 lbs / 2 inches wide | 36 lbs / 2 inches wide |

Breaking strength | ASTM D751 | 170 psi | 1084 psi |

Dimensional stability | ASTM D1204 | 0.7% maximum length change | go through |

Waterproof | ASTM D4068 | No moisture penetration | go through |

7 days shear strength | ASTM C482 | 50 psi | 87 psi |

7 days flooding | ASTM C482 | 50 psi | 77 psi |

4 Week Shear Strength | ASTM C482 | 50 psi | 96 psi |

12 Week Shear Strength | ASTM C482 | 50 psi | 90 psi |

100 days flooding | ASTM C482 | 50 psi | 120 psi |

water vapor permeability | ASTM E96 | 0.75 perm |