Vulcanizing machine with portable conveyor belt ZLJ-650/ Vulcanizing machine

- $2600.00 /set

- 1 set

- Qingdao Antai Mining Machinery Co., Ltd.

- Shandong, China

- Mr Robbie Wang

| Health status: | new | Cooldown: | about 5 minutes |

| port: | Qingdao Port | Vulcanization temperature: | 145°C or according to conveyor belt |

| year: | 2019 | Heating plate angle: | 18/22/30 |

| Certification: | CE ISO SGS | Packaging Details: | Seaworthy wooden box |

| Dimensions (L*W*H): | 1080x1220x630 | Vulcanized plate: | 1420mm-830mm |

| Belt Width: | 500-3000mm | strength: | 12.18kw |

| type: | Vulcanizing machine | Warranty: | 2 years |

| Package preview: | Voltage: | 220v/360V or customized | |

| Material: | aluminum alloy | payment terms: | L/C, T/T |

| Name: | Vulcanizing machine | brand: | Aetna |

| weight: | 410 kg | Packaging Details: | Seaworthy wooden case or customized. |

| After-sales service provided: | Video technical support, engineers can service machinery overseas | Supply capacity: | 200 sets per month |

| place of origin; place of origin: | Shandong China | heating time: | less than 20 minutes |

Portable conveyor belt vulcanizing machine ZLJ-650/vulcanizing machine

Qingdao Antai Mining Machinery Co., Ltd.--China vulcanizing machine manufacturer

ZLJ conveyor belt curing machine is made of high-strength aluminum alloy. Our machines have great advantages over others by using our company's own products ONE-PIECE HEATING FILM and RUBBER PRESS BAG. This makes the machine work smoothly, with high thermal efficiency and uniform temperature. Also, the automatic electric control box can provide a uniform pressure of 0-2mpa. It is easy to operate, portable, and has superior performance. It is widely used in metallurgical mines, cement plants, power plants, ports, docks, building materials, and chemical industries. It is the best equipment for splicing and repairing conveyor belts.

500, 650, 800, 1000, 1200, 1400, 1600, 1800, 2000, 2200 (mm).

●According to the length of the conveyor belt joint, it is divided into:

250, 300, 350, 400, 500, 600, 700, 800, 1000, 1200 (mm).

●According to the shape of the hot plate: rectangle -72°, parallelogram -90°.

●By voltage: 220V, 380V, 440V, 660V or customized.

●According to the cooling method, it can be divided into:

Rapid water cooling and natural cooling.

| ZLJ Conveyor Belt Vulcanizer Technical Parameters | |||||

Title here.

●Heating method: electric heating.

●Boost type: hydraulic type.

●Power supply voltage: 1140V, 660V, 450V, 415V, 380V, 220V, 50Hz or customized.

●The heating power per unit area of a single heating plate is ≥7000W/㎡.

● Equipped with a digital temperature control system, the vulcanization temperature can be adjusted from 0-199℃.

●Heating time (from room temperature to 145°C) ≤ 25 minutes.

●Vulcanization pressure can be set to ≤2MPa.

●Automatic control of temperature rise, heat preservation and temperature limit protection.

main feature

1.According to the applicable tape width, it is divided into: 500, 650, 800, 1000, 1200, 1400, 1600, 1800, 2000, 2200, 2400 (mm).

2. According to the length of the tape, it is divided into: 250, 300, 350, 400, 500, 600, 700, 800, 1030, 1200 (mm).

3. Heat plate shape: rectangle or parallelogram.

4. Voltage: 220v, 380v, 660v, 1140, etc.custom made.

5. According to the configuration, it can be divided into fast water cooling type and natural cooling type.

6. Heating method: electric heating.

7. Pressurized type: hydraulic type.

8. Equipped with a digital temperature control system, the curing temperature is adjustable from 0-199°C.

9. Heating time (from room temperature to 145°C) ≤ 20 minutes.

10.Cooling time: about 5 minutes.

11. The vulcanization pressure can be set to ≤2MPa;

12. Automatic control of temperature rise, heat preservation and temperature limit protection.

main part

Product name: Rubber water pressure bag

Card:AetnaThe original: China

The rubber water pressure bag is another self-developed product of Antai Company in 2005. The company invested 8 million yuan in research and development. The technology is mature and it is well received by domestic and foreign markets.

clean appearance;

The compression area is large. Withstand high pressure within 3Mpa and provide uniform pressure;

Portable and easy to operate.

main part two

Name: One-piece one-piece rubber heating film

Card:Aetna

The original:China

We successfully developed ONE-PIECE integrated rubber heating film in 2006. The heating film is the same size as the heating plate.

clean appearance;

Safe and reliable;

Excellent temperature uniformity;

structural durability;

Emergency maintenance time is short.

main part three

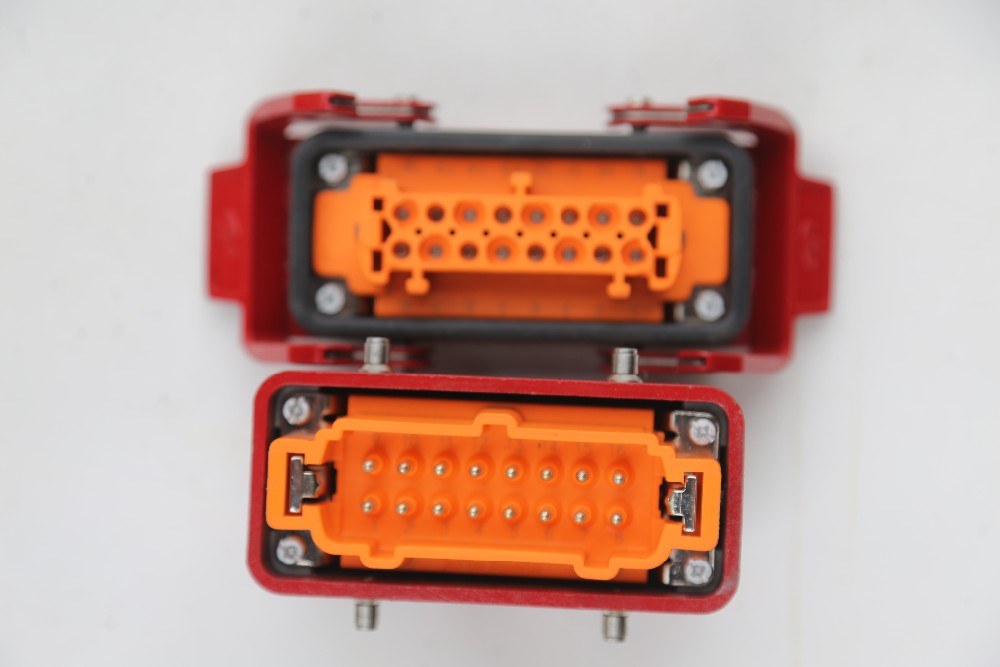

Name: control box

Card:Aetna

The original:China

Self-developed control box. Clear operation buttons and indicator lights. Automatic and manual operation modes.

Main Part IV

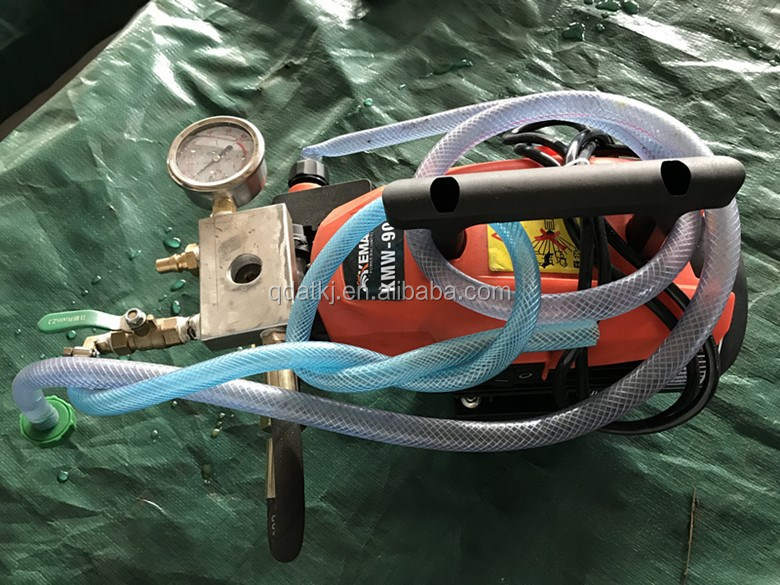

Name: pressure pump

Card:Aetna

The original:China

Improved pressurized water pump, compact and portable.

Provide enough pressure around 1Mpa.

pre-sale service

* Inquiry and consultation support.

* Sample testing support.

* Check out our factory.

After-sales service

* Training how to install the machine, training how to use the machine.

* If there is any problem with the accessories during the warranty period, they will be replaced with new ones for free.

Qingdao Antai Mining Machinery Co., Ltd.--Conveyor belt vulcanizing machine made in China

Qingdao Antai Mining Machinery Co., Ltd. was established in 2000. It is a branch of Antai Heavy Industry Group. Based on 30 years of experience in design and development in the field of industrial equipment and more than 17 years in the field of thermal splices for heavy-duty conveyor belts, the group has managed to achieve a stable position in both areas. Domestically and internationally.

Over the years, the company's strict quality control and customer-centric guiding ideology have provided great help for the development at home and abroad. As one of the largest sustainable development companies in China,Our company's quality standard is recognized by the Ministry of Industry and Information Technology as the industry standard for conveyor belt vulcanizationAfter a series of rigorous evaluation tests.

We have our own R&D team. In 2010, Antai Mining Machinery successfully developed advanced vulcanizer heating elements and pressure elements with independent intellectual property rights, which reduced the product failure rate. At present, our heating and pressure components have been widely used by domestic vulcanizing machine manufacturers, greatly improving the international competitiveness of domestic vulcanizing machines.

Packaging and delivery details.

Title here.

Packaging and transportation: Our packing box adopts fumigation-free box, which is neat in appearance, easy to load and unload, and meets the customs export standard.

Any question or you are interested in vulcanizing machine, please feel free to contact me.

1. Whatsapp: 0086-18669717536;

2. WeChat/Facebook: 18669717536;

3.ins:chloe.zhang.1253

4. Zalo: 0086 186 6971 7536